Rubber frame ultrasonic cleaning device and method for liquid crystal screen production and processing

A technology for cleaning devices and liquid crystal screens, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve problems such as inability to clean, and achieve the effects of simple operation and increased practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

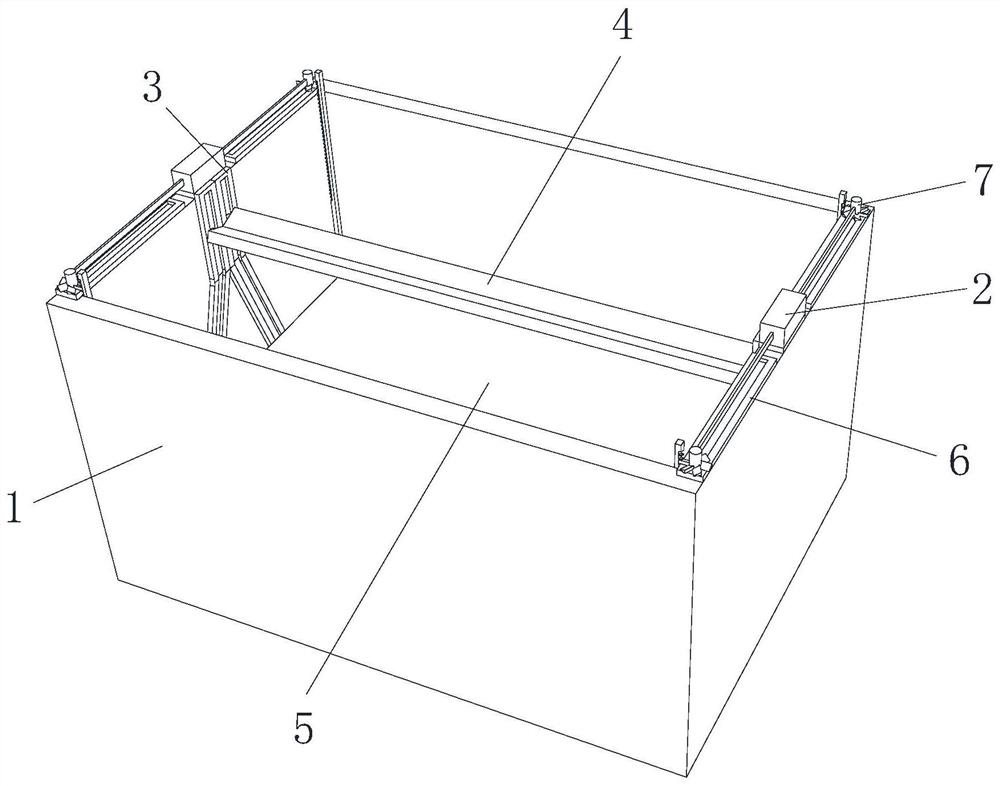

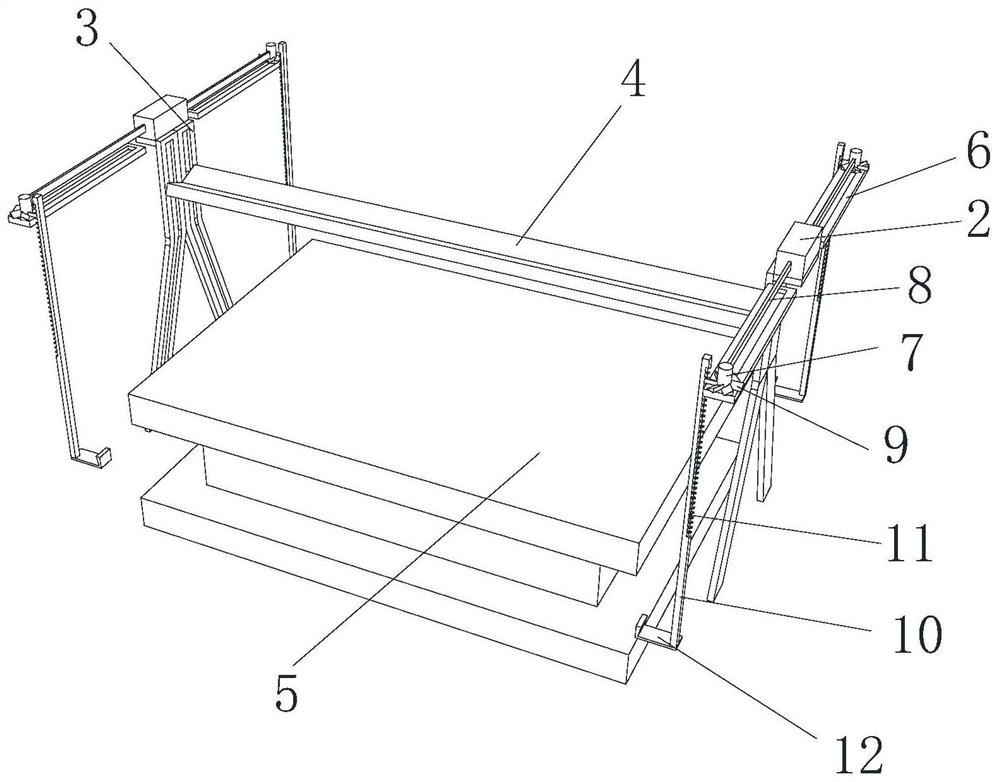

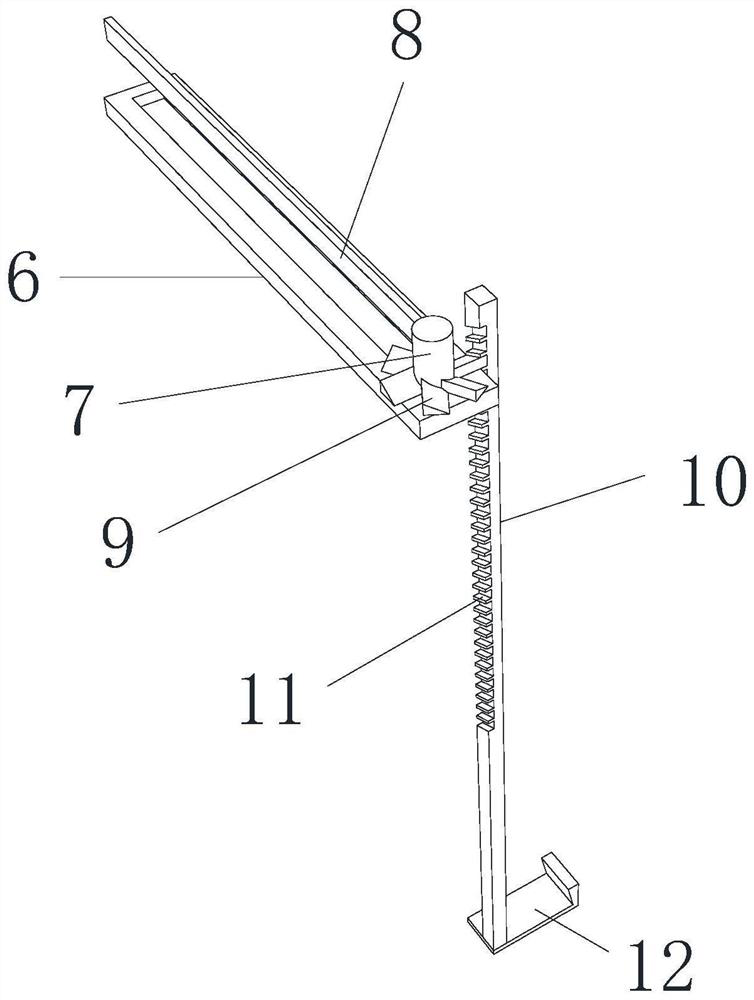

[0031] Embodiment: the plastic frame ultrasonic cleaning device that liquid crystal screen production and processing is used, as figure 1 - Figure 5 As shown, the cleaning box 1 is included, and the upper surface of the cleaning box 1 is symmetrically provided with installation boxes 2 for operation. 3. A bearing plate 4 is movably clamped between the guide rails 3 on both sides. A control device for controlling lifting and rotation is installed on the cleaning box 1 at the side of the installation box 2. A useful On the telescopic platform 5 that is buffered and kept stable, a winding device for controlling the operating position is provided in the installation box 2, and the guide track 3 is located on the side wall of the cleaning box 1 at a position corresponding to the installation box 2 and the cleaning box 1 are fixedly connected, and there are two guide rails 3 on each side, and the two guide rails 3 on the same side are combined in a Y shape, and the positions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com