Lathe with waste collecting function

A waste collection and function technology, applied in the field of lathes, can solve problems such as blockage and affect the normal use of the lathe, and achieve the effect of avoiding blockage and reducing the pressure of manual work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

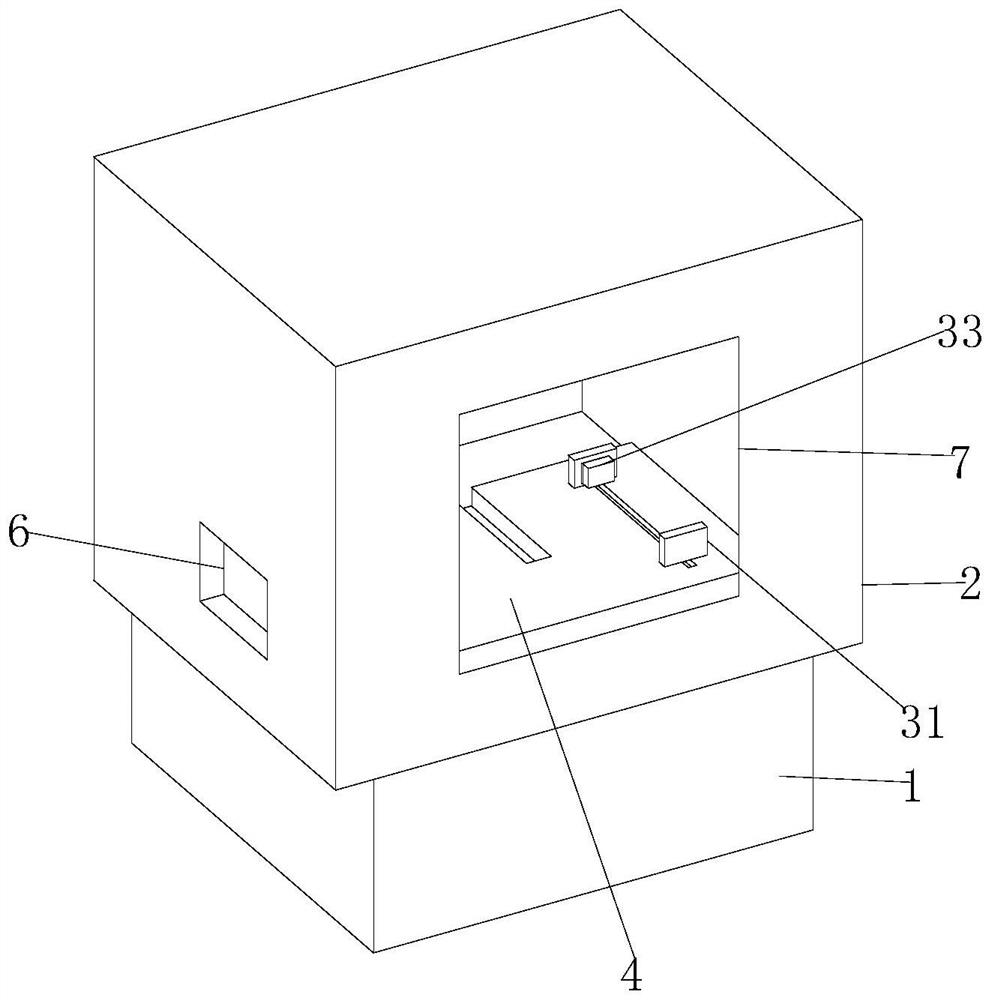

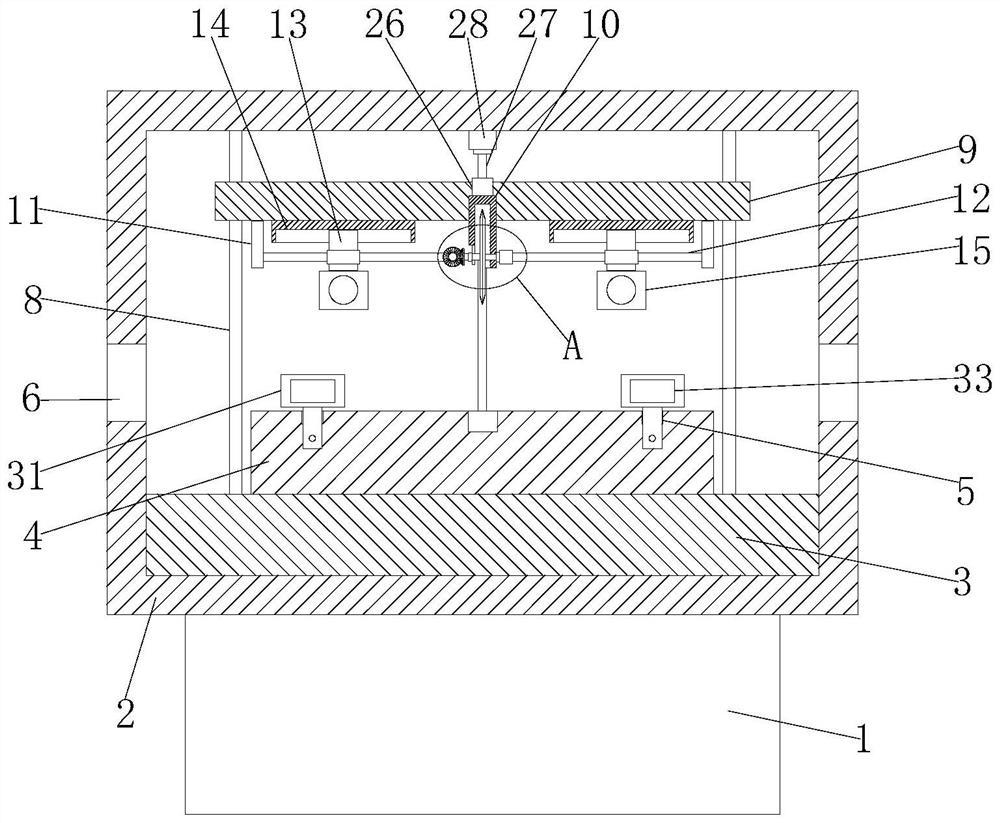

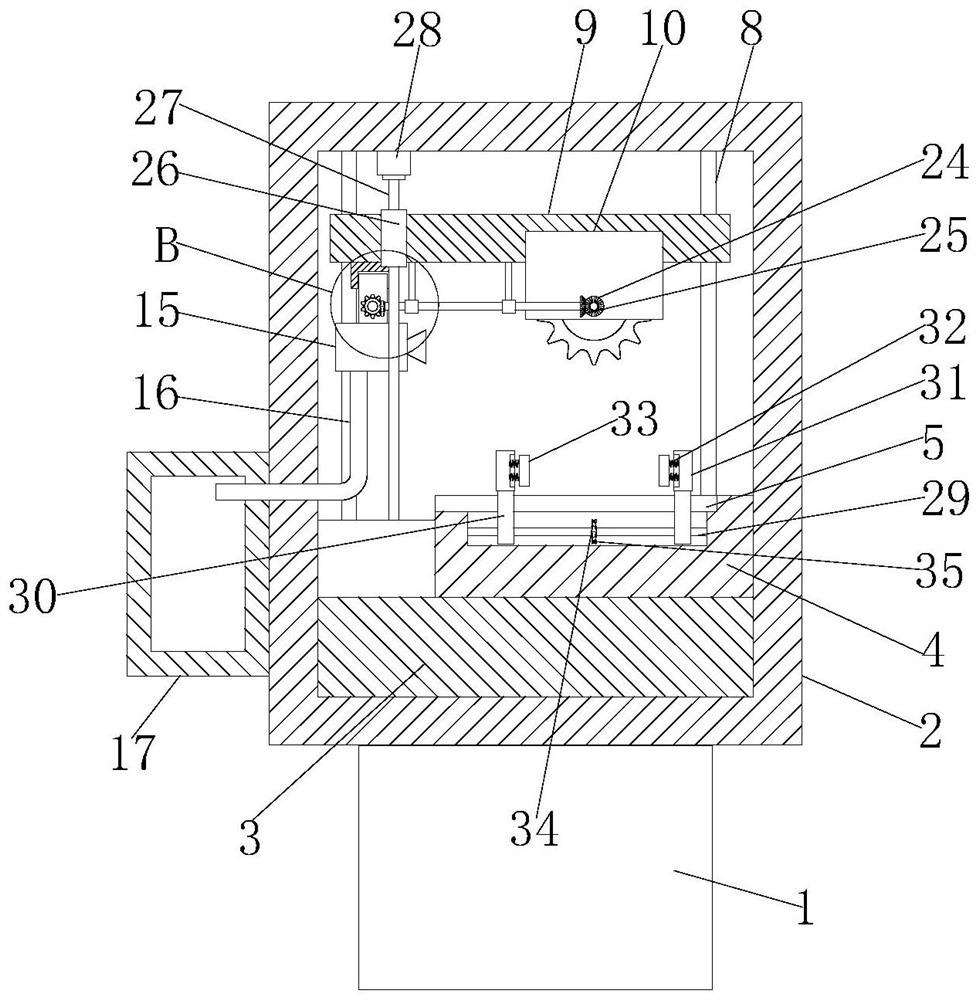

[0027] refer to Figure 1-7 , a lathe with waste collection function, comprising a base 1, the top of the base 1 is fixedly connected with an outer protective cover 2, the bottom inner wall of the outer protective cover 2 is fixedly provided with a backing plate 3, and the top of the backing plate 3 is fixedly arranged There is a workbench 4, and two chutes 5 are provided on the workbench 4, and a clamping mechanism is arranged in the chute 5. The left and right sides of the outer protective cover 2 are provided with feed troughs 6, and one side of the outer protective cover 2 is provided with The glass window 7 and the top of the backing plate 3 are fixedly connected with four limit rods 8, and the sliding sleeves on the four limit rods 8 are provided with the same limit top plate 9, and the bottom of the limit top plate 9 is fixedly connected with an installation sleeve 10, The installation cover 10 is provided with a cutting mechanism, the bottom of the limit top plate 9 is...

Embodiment 2

[0039] The difference from Embodiment 1 is that the chain 35 is connected with a second sprocket 36, the second sprocket 36 is fixedly sleeved with a linkage shaft 37, and one end of the linkage shaft 37 is fixedly connected with a third bevel gear 38. The third bevel gear 38 is meshed with a fourth bevel gear 39, and the fourth bevel gear 39 is fixedly sleeved on the drive screw 27. By setting the fourth bevel gear 39, the third bevel gear 38 can be rotated, and the second sprocket 36 The fixed sleeve is provided with a trigger shaft 40 , and a knob 41 is fixedly connected to the trigger shaft 40 .

[0040] Working principle, when in use, the workpiece is first placed on the workbench 4 through the trough 6 on the outer protective cover 2, and then the first motor 21 is started, and the first motor 21 can rotate the rotating shaft 22. Grinding wheel 23 just can cut workpiece, and the first bevel gear 24 on the rotating shaft 22 can rotate the second bevel gear 25 and connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com