Three-connecting-rod manipulator actuator fault detection method based on event triggering mechanism

A technology of fault detection and event triggering, applied in manipulators, manufacturing tools, etc., can solve problems such as transmission delays, achieve the effects of saving communication bandwidth, ensuring system performance, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

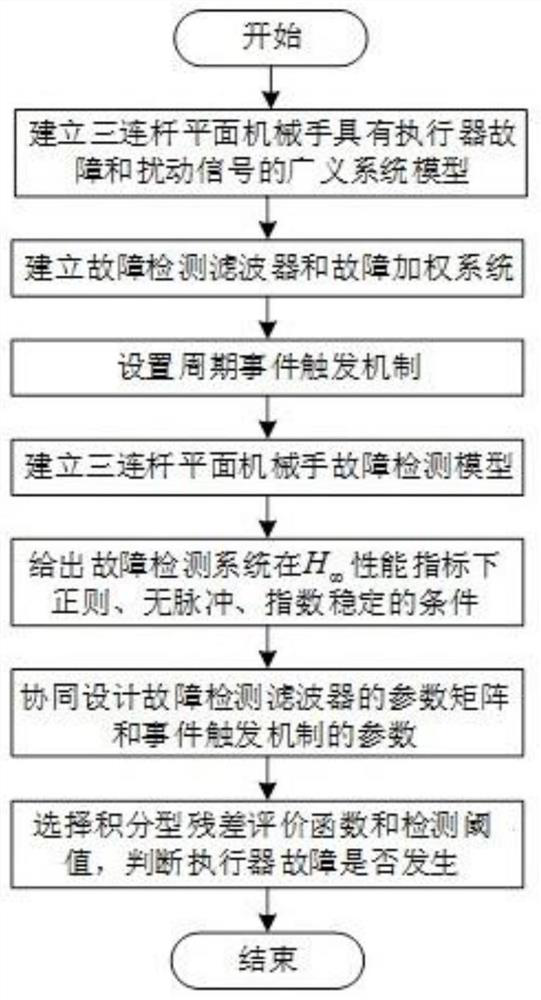

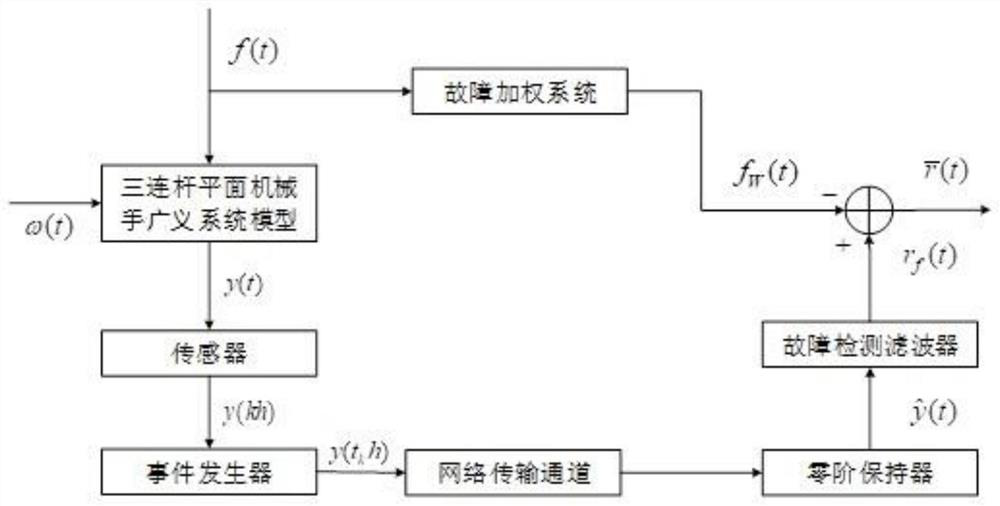

[0053] A fault detection method for a three-link manipulator actuator based on an event-triggered mechanism, such as figure 1 , figure 2 and image 3 As shown, including the following steps:

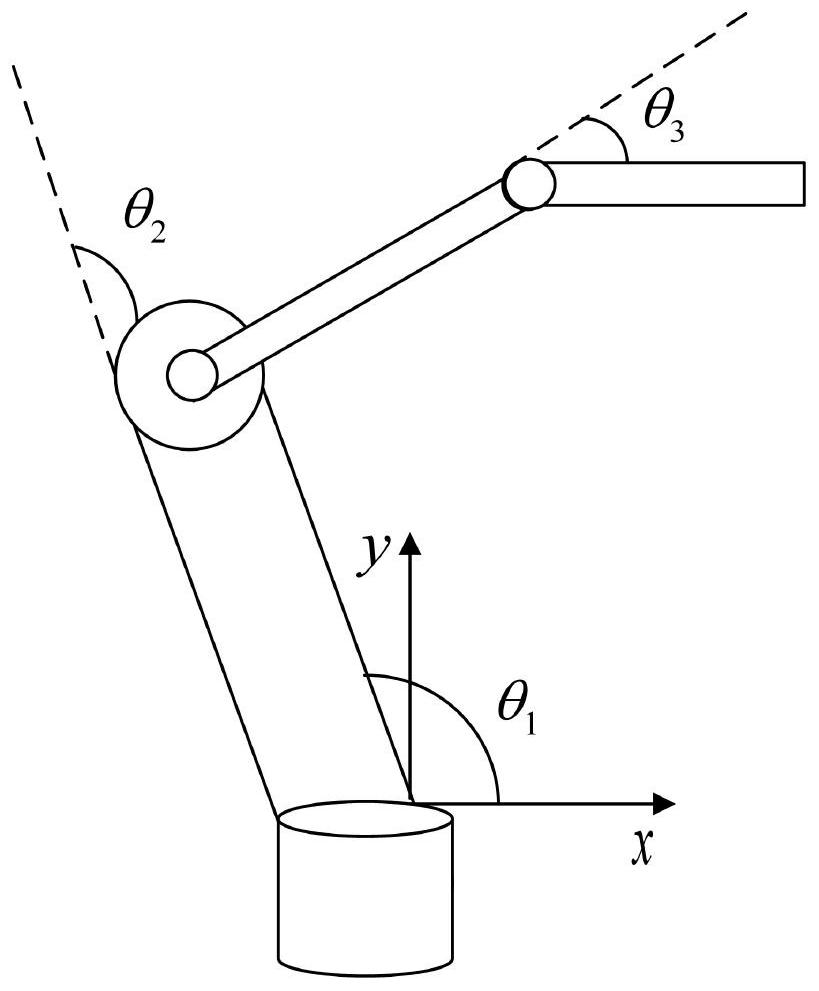

[0054] Step 1: Establish the nonlinear dynamic model of the three-link planar manipulator in the joint coordinate system, and then convert it into a linear model in the Cartesian coordinate system, and then select the linearized balance point, considering the actuator failure parameters and external disturbances Input parameters to design a generalized system model of a three-link planar manipulator:

[0055] Set the three-dimensional model for the three-link manipulator and set the joint coordinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com