Patents

Literature

34 results about "Actuator fault detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

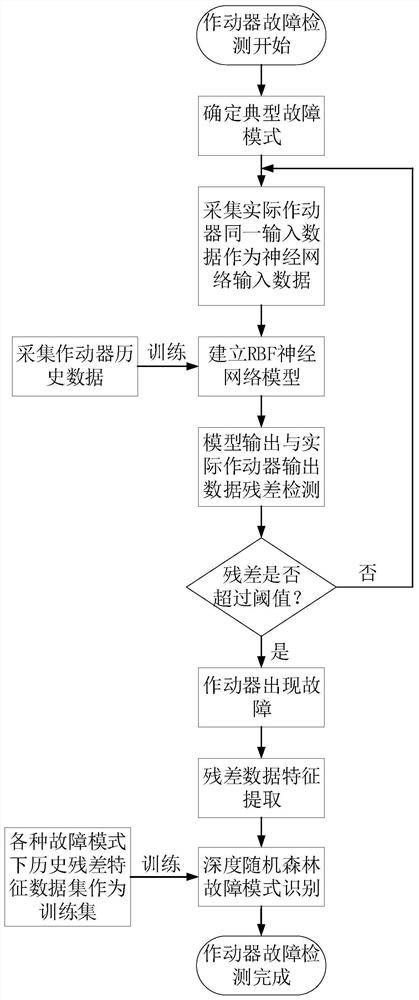

Aircraft actuator fault detection and diagnosis method based on depth random forest algorithm

ActiveCN108594788AAccurately describe input and output characteristicsQuick checkElectric testing/monitoringData setFeature extraction

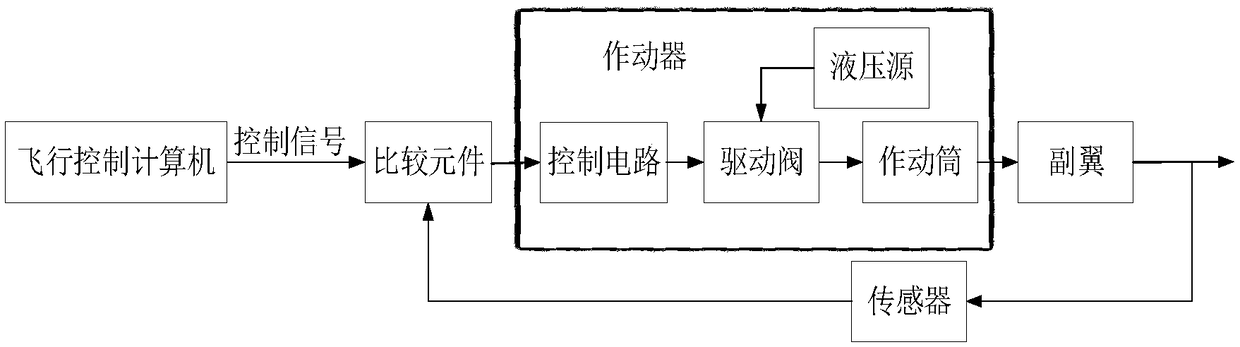

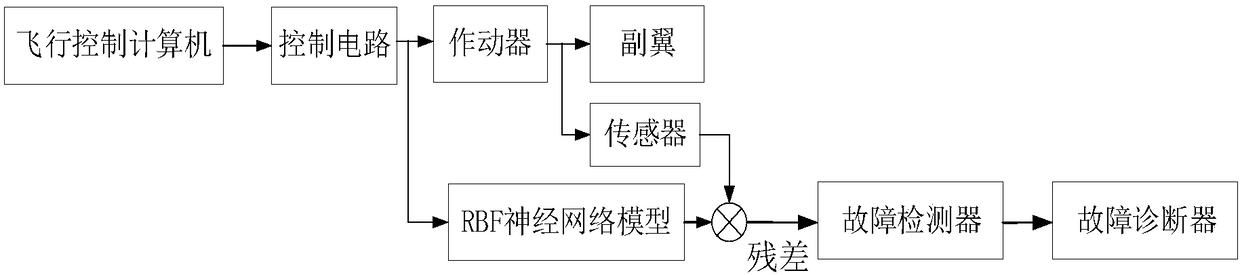

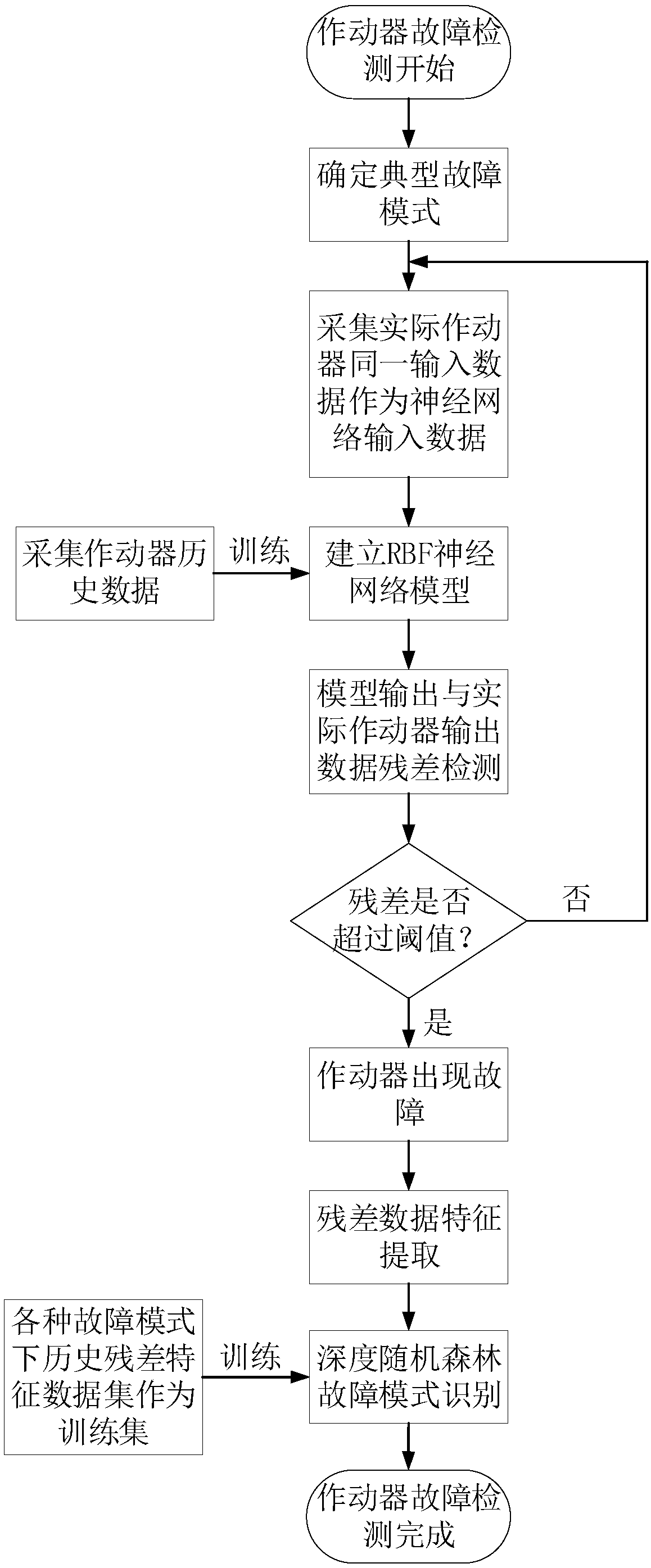

The invention discloses an aircraft actuator fault detection and diagnosis method based on a depth random forest algorithm. The method includes: firstly, summarizing the fault mode of an aircraft actuator; establishing an RBF neural network, and collecting the input and output data of the aircraft actuator under the normal working condition to serve as training data, and training the parameters inthe neural network model to obtain analysis redundancy of the monitored actuator; analyzing the residual data of the output signals by collecting the output of the actual actuator and the neural network model, and after the feature extraction, inputting the feature data set into a trained depth random forest multi-classifier for fault mode recognition. According to the invention, the complex nonlinear input and output relation of the aircraft actuator can be accurately simulated by the neural network, the fault mode is accurately recognized by a depth random forest strong classifier, and moreover, the method has the advantages of parallel calculation and high running speed, can be integrated into a flight management computer of an aircraft, realizes the online real-time monitoring, and the accuracy and the efficiency of fault diagnosis of the aircraft actuator are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

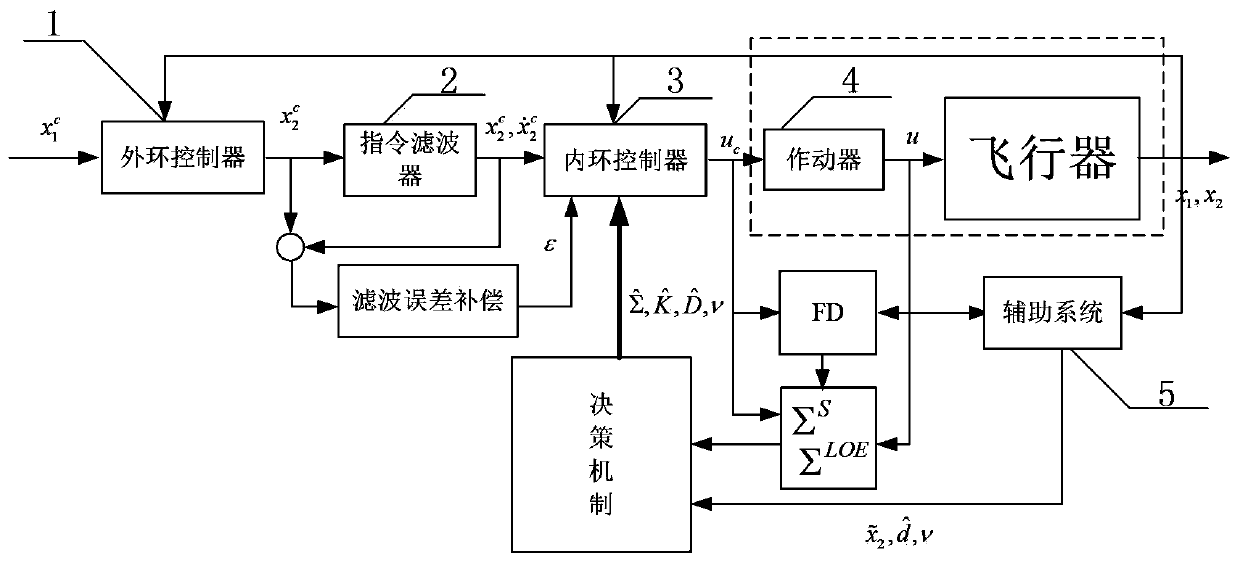

Dynamic-actuator aircraft attitude distributed type fault-tolerant control system

ActiveCN104049638AImprove robustnessGood effectAttitude controlActuator fault detectionSelf adaptive

The invention discloses a dynamic-actuator aircraft attitude distributed type fault-tolerant control system. The system comprises an actuator fault detection and identification unit, an auxiliary system based on an observer and an inversion fault-tolerant control algorithm based on order filtering. According to the distributed type fault-tolerant control system, the actuator fault detection and identification unit is used for obtaining fault information of actuators in real time, the self-adaptive sliding-mode observer is obtained according to an attitude angular speed ring, the observer has strong robustness, an undetermined or interference upper bound does not need to be known, and control surface damage fault information an interference information are both hidden in the observer; a fault-tolerant controller is obtained based on an observer model. Robustness fault-tolerant control over various faults of different types under the multi-fault condition is achieved, the fault-tolerant control system is applied to near-space vehicle attitude stable control and tracking control under the condition of faults of the actuators and the control surface, flying attitude robustness fault-tolerant control is achieved, and good control performance and effect are achieved.

Owner:SHANDONG JIELIER FERTILIZER CO LTD

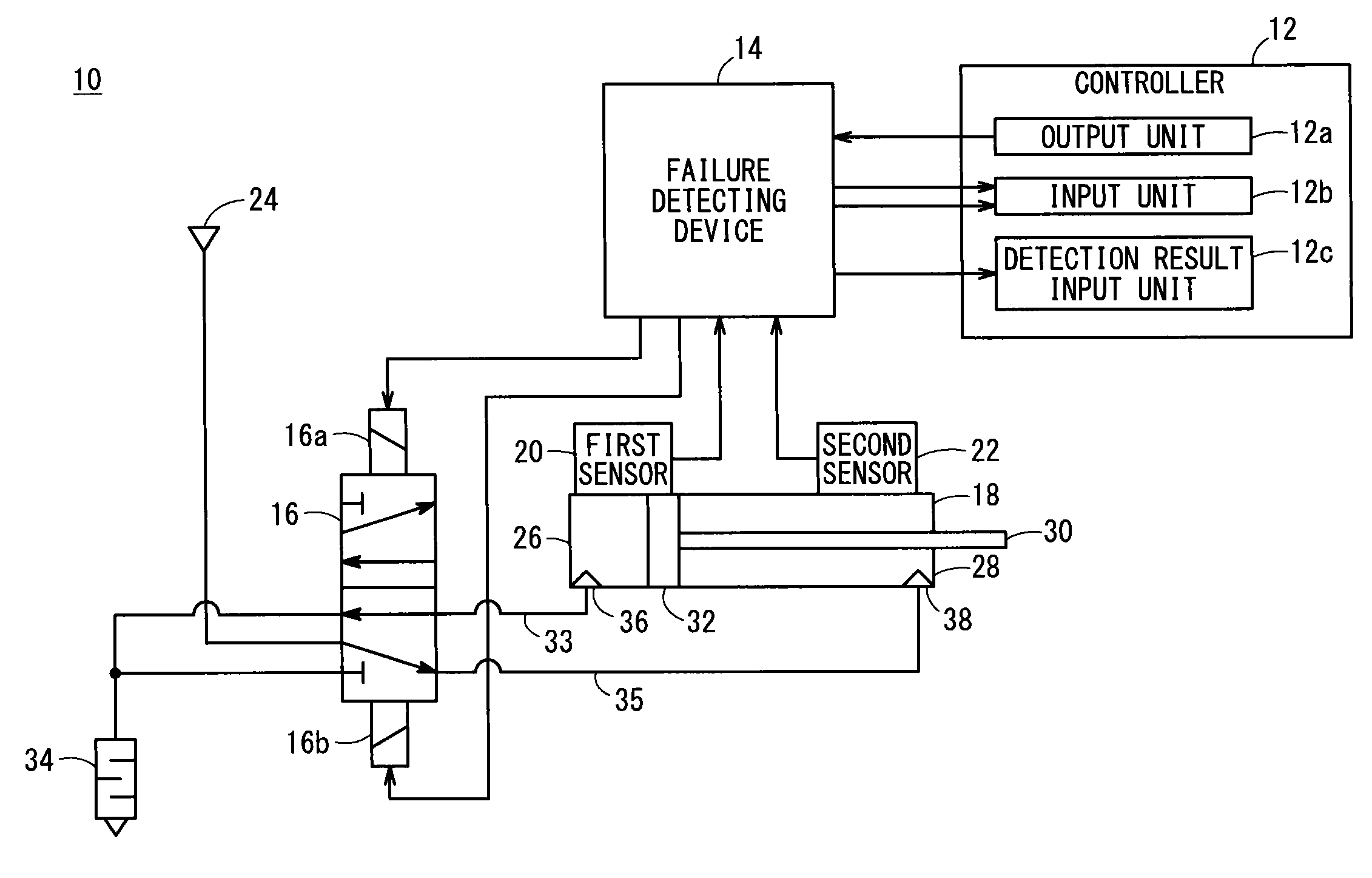

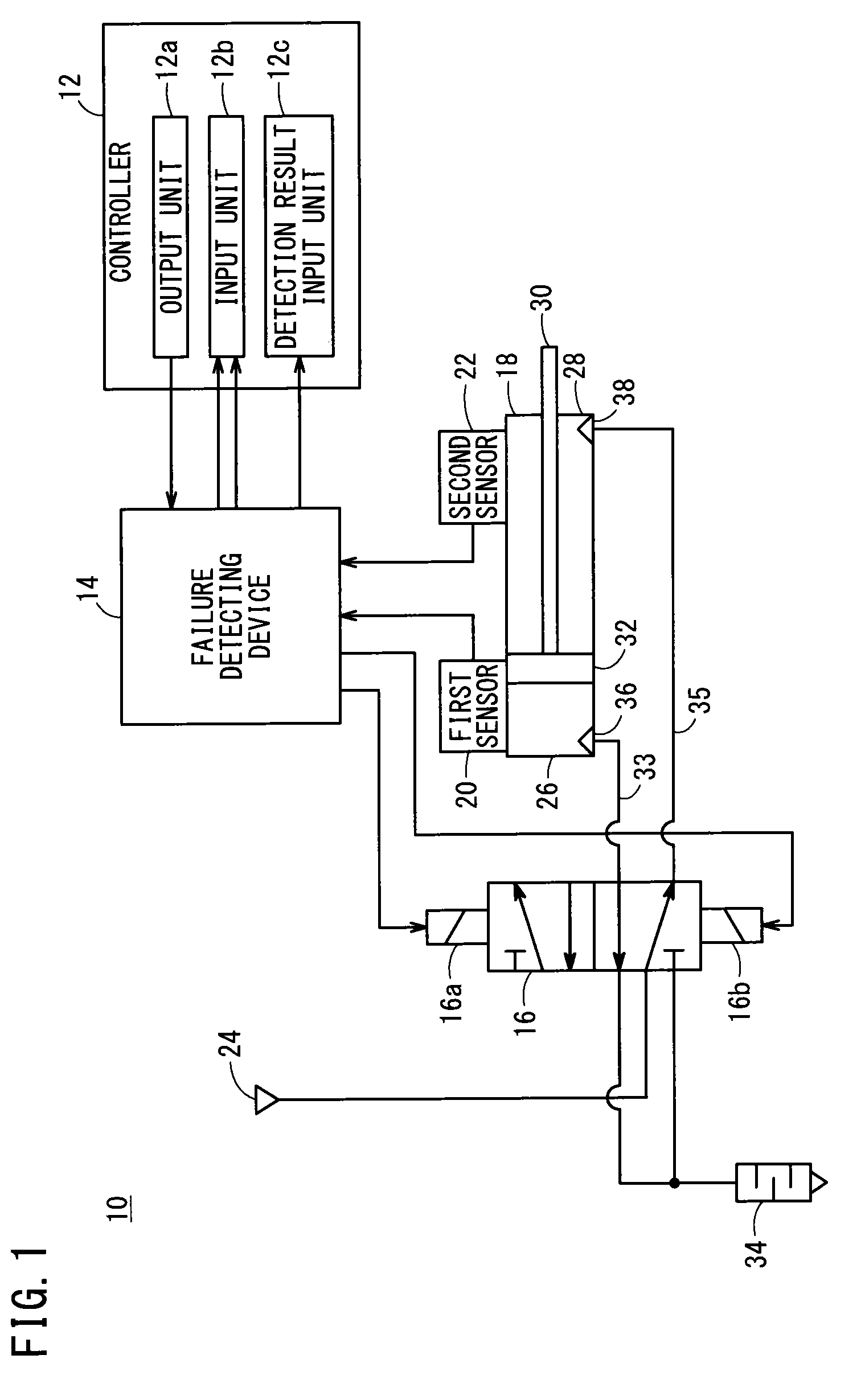

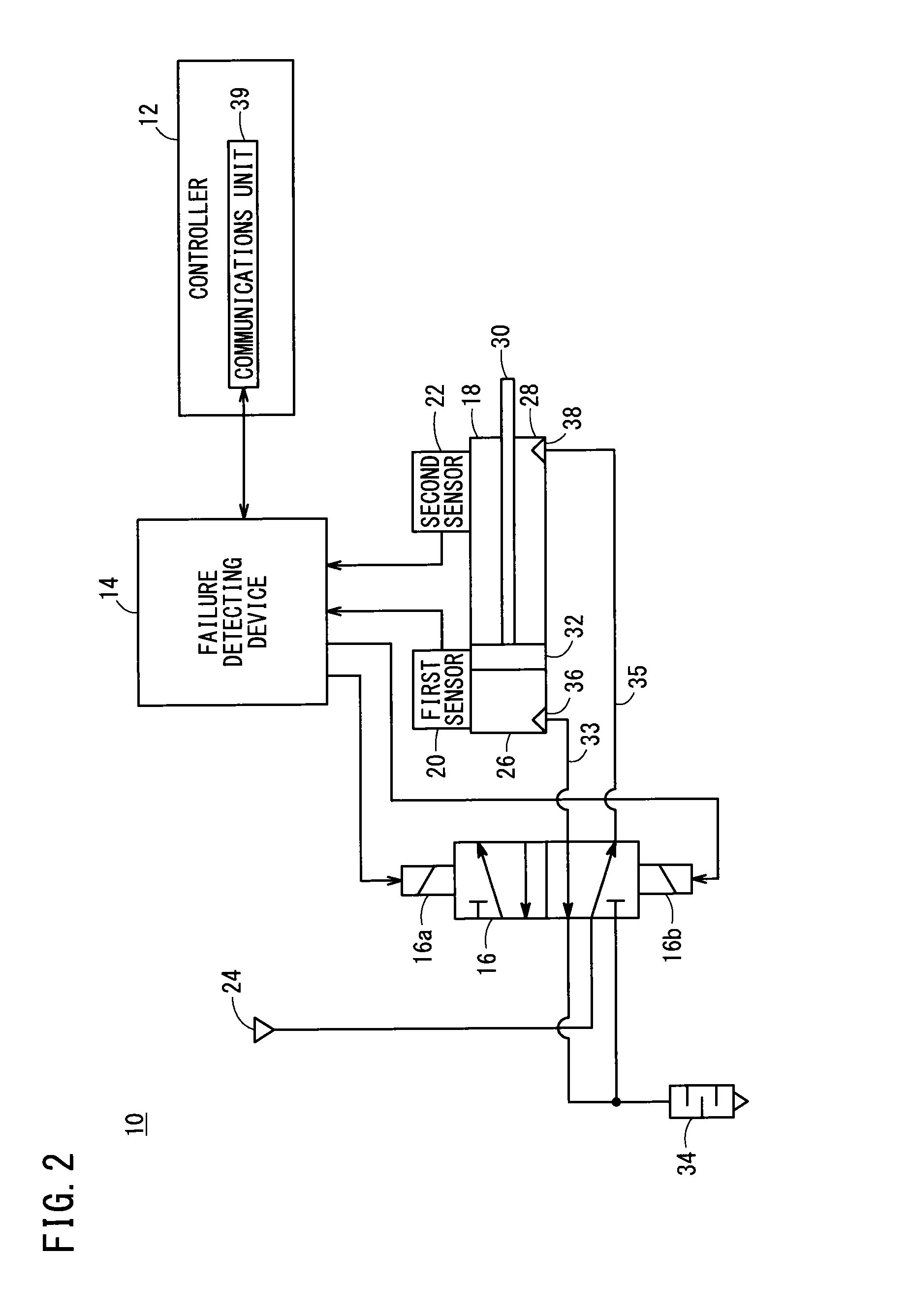

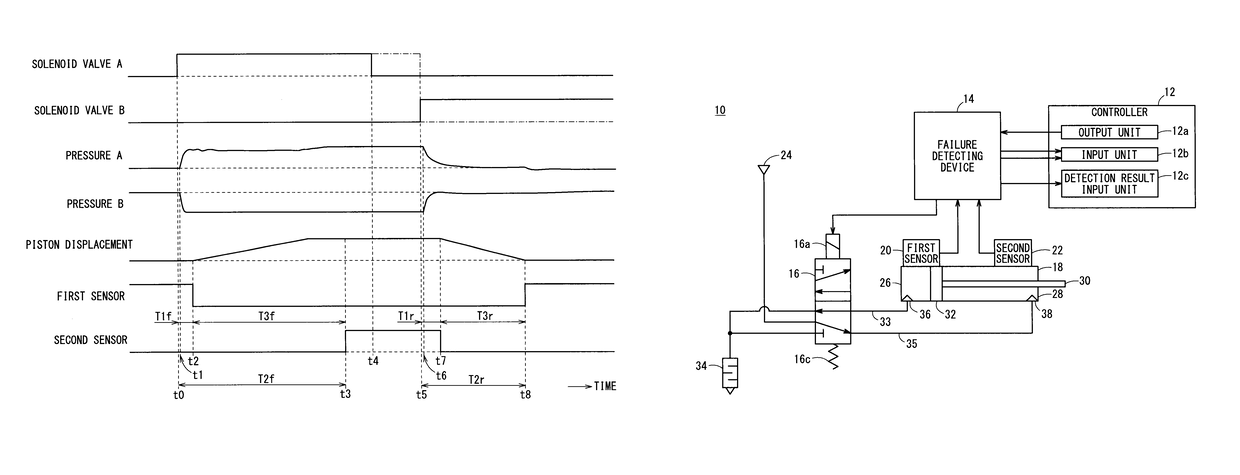

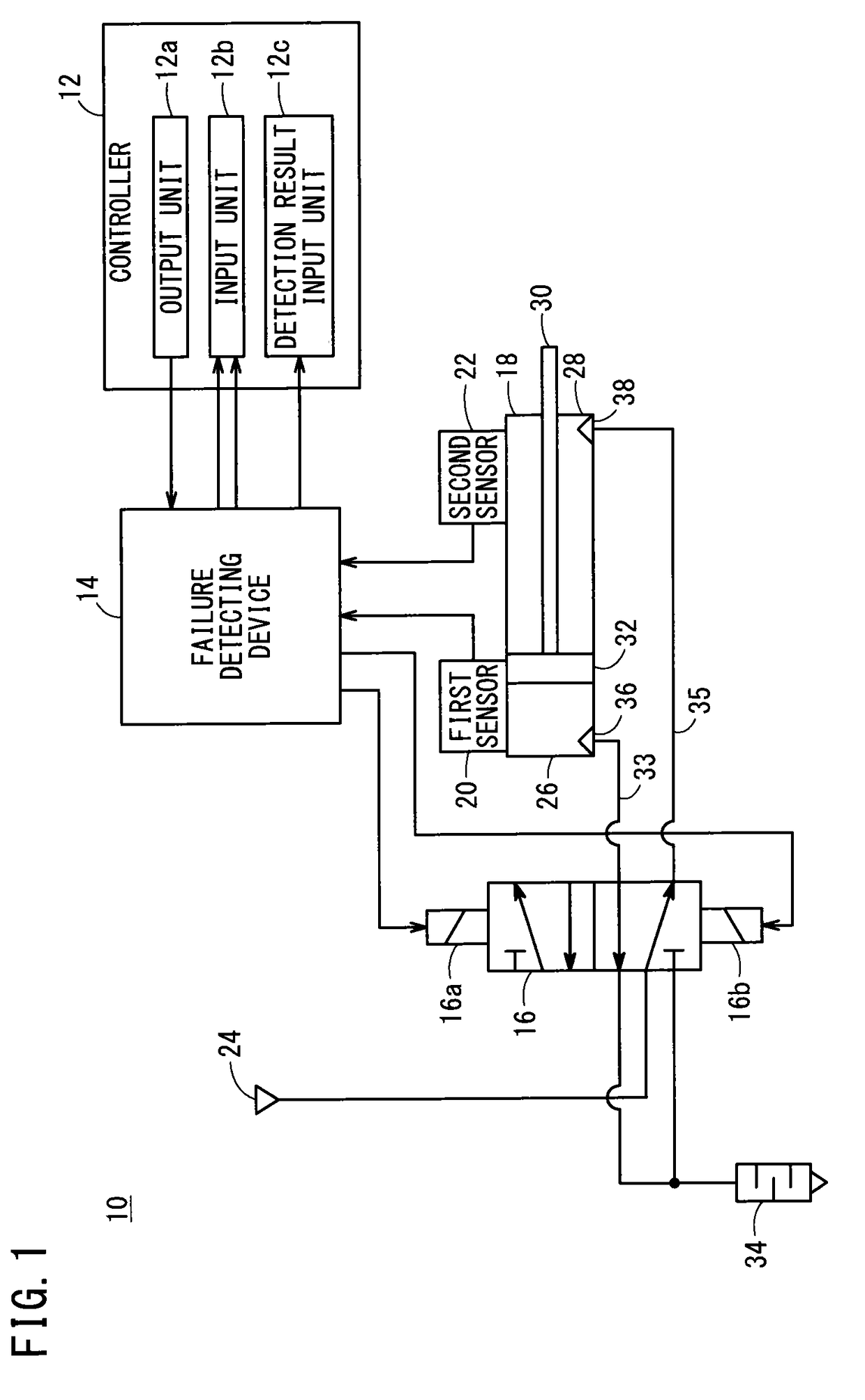

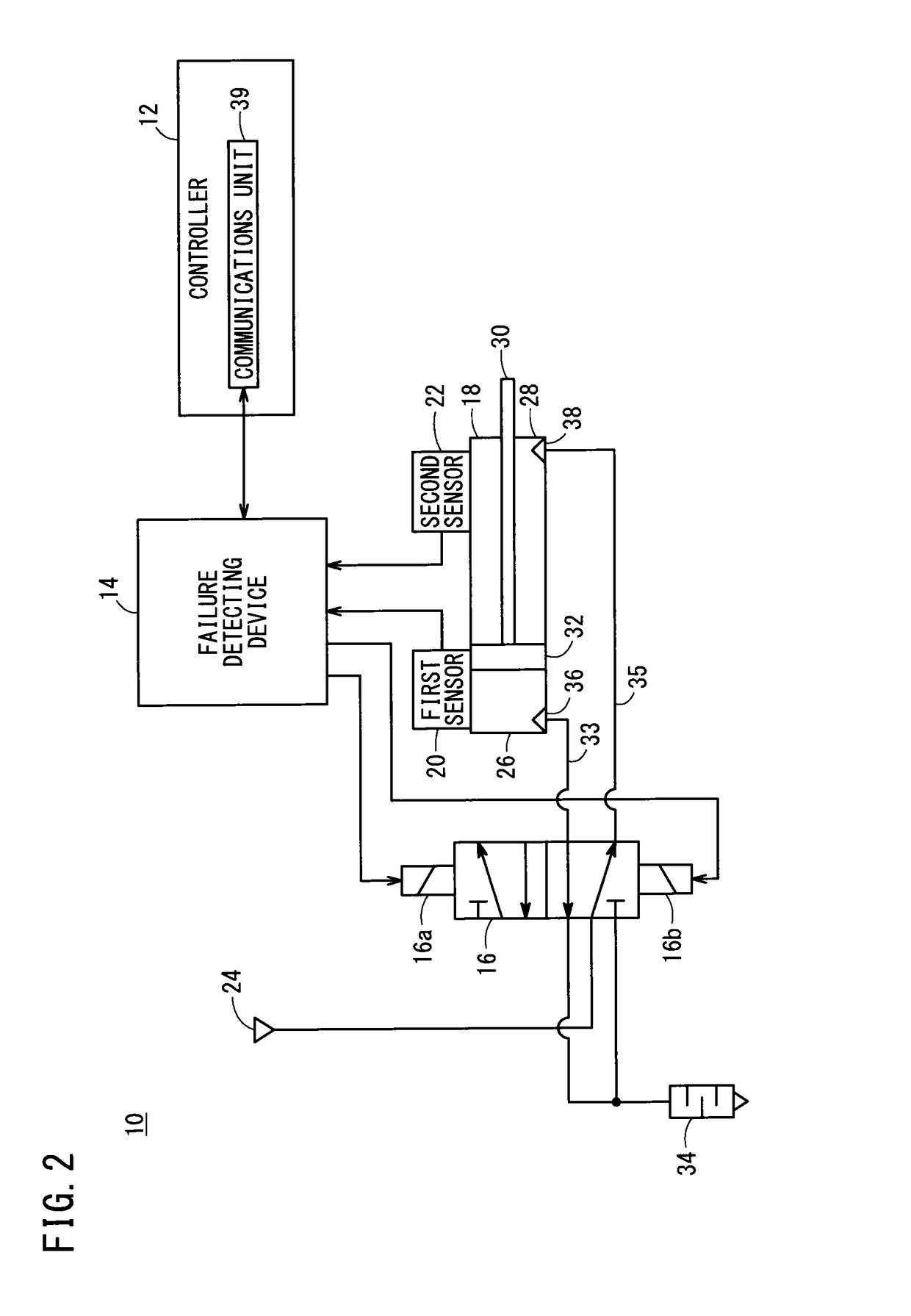

Fault detection system for actuator

ActiveUS20150007713A1Easy to detectImprove maintainabilityPlug gaugesMachine part testingEngineeringActuator fault detection

A failure detecting device of a fault detection system includes a detection time calculator, which calculates a stroke time T3 required for a piston to travel between one end and another end of an actuator based on detection signals from a first sensor and a second sensor, a statistical processor that performs a predetermined statistical calculation with respect to the stroke time T3, and a fault response detector, which detects whether or not a fault of the actuator has occurred based on a processing result of the statistical processor.

Owner:SMC CORP

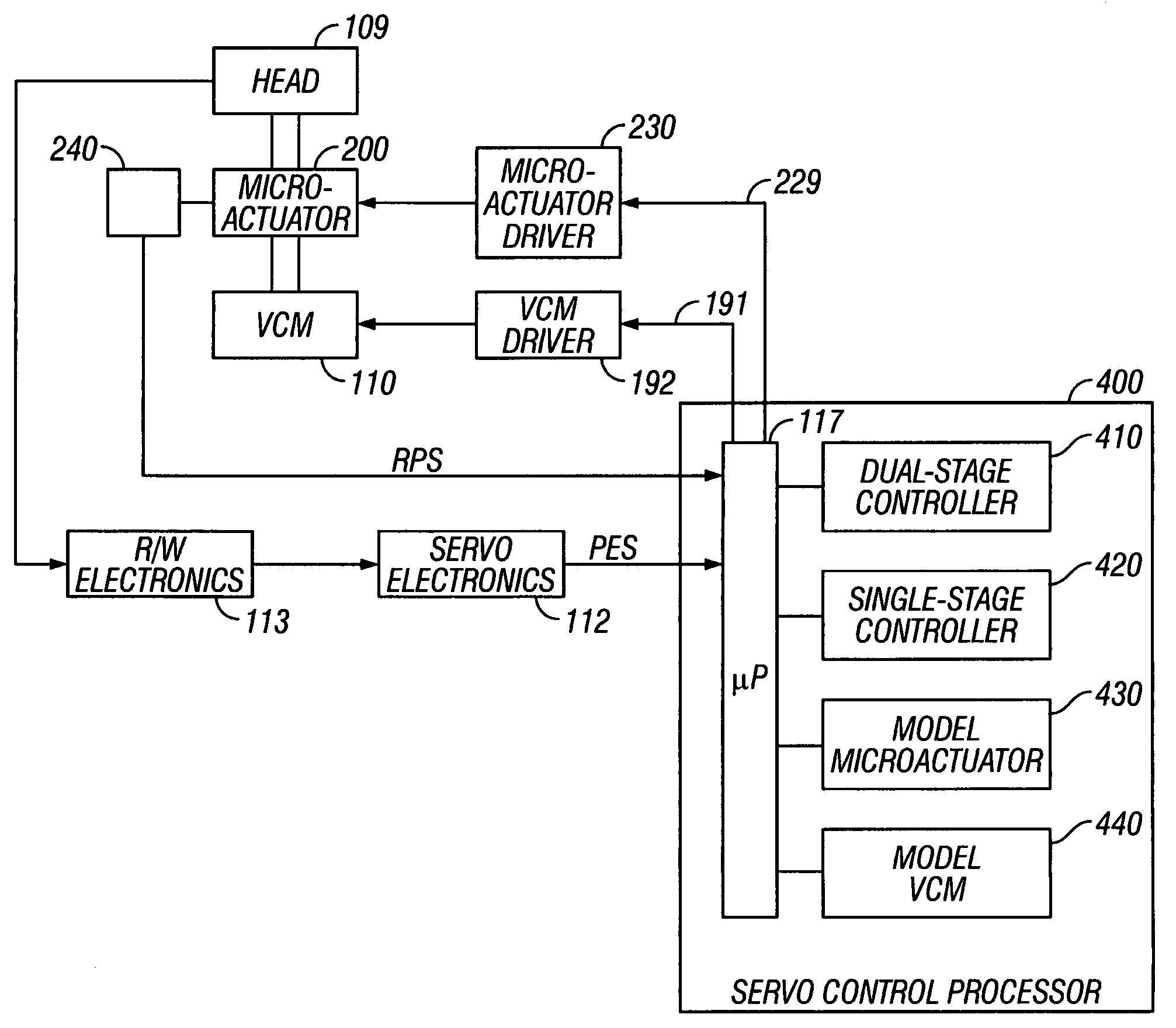

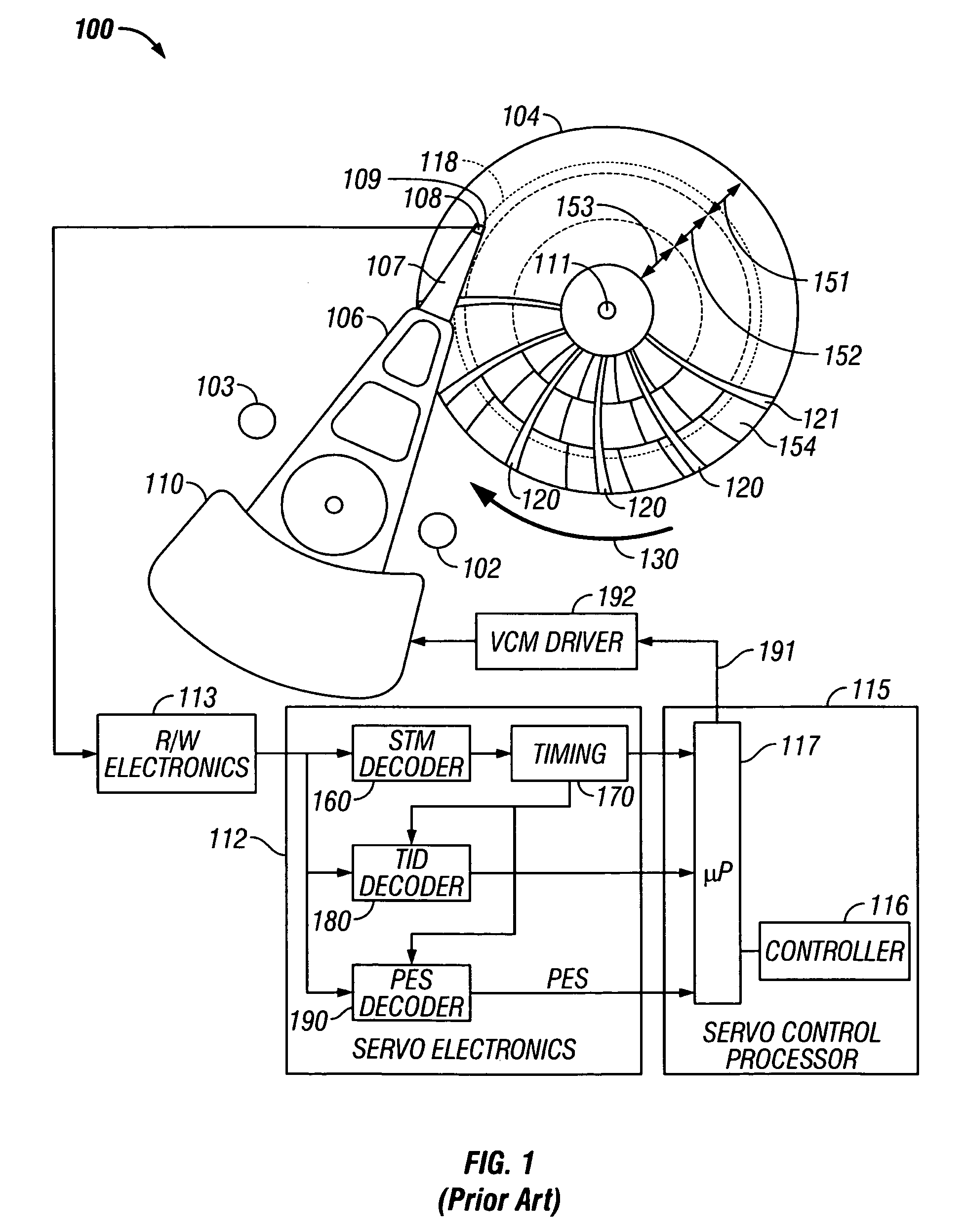

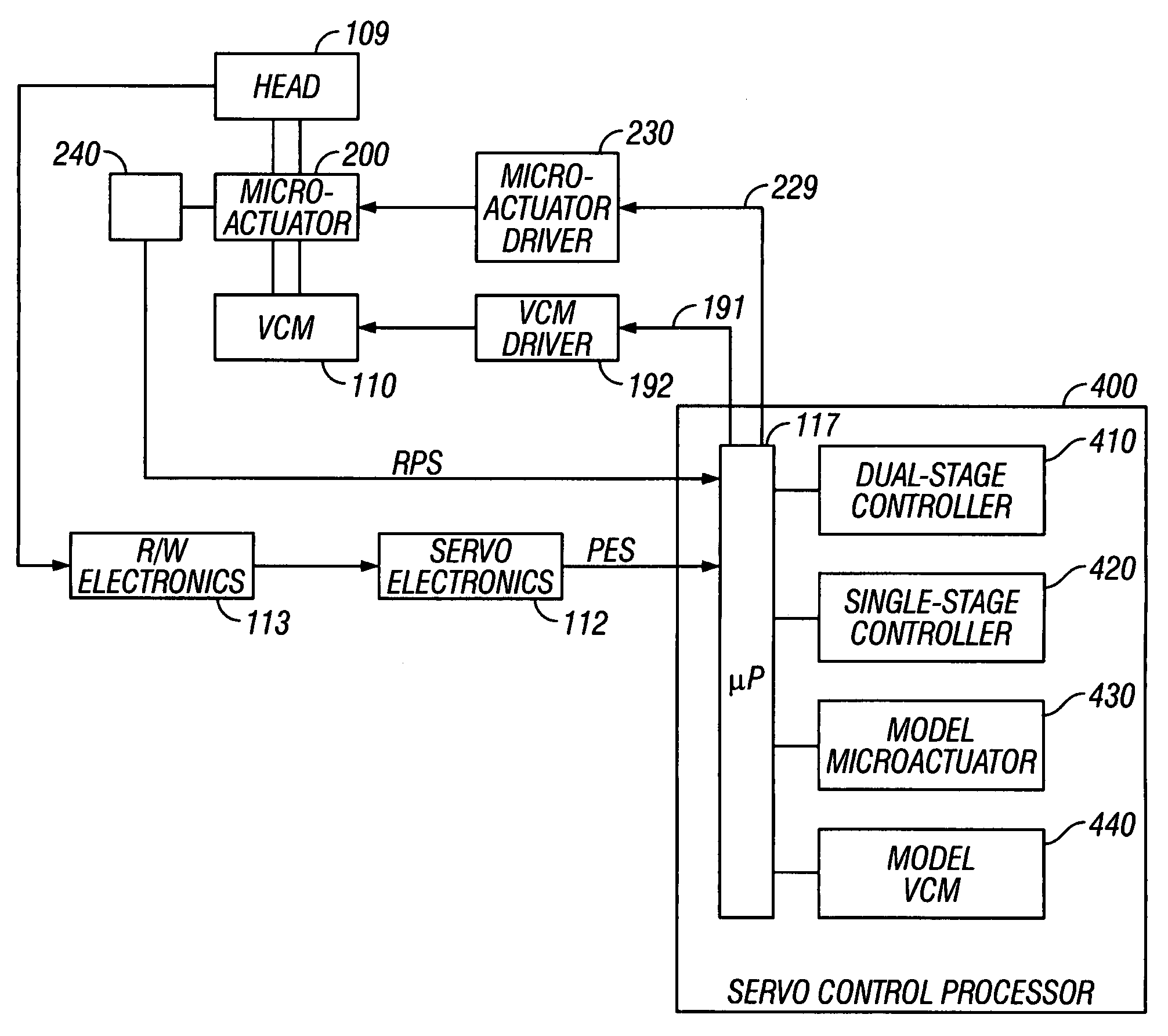

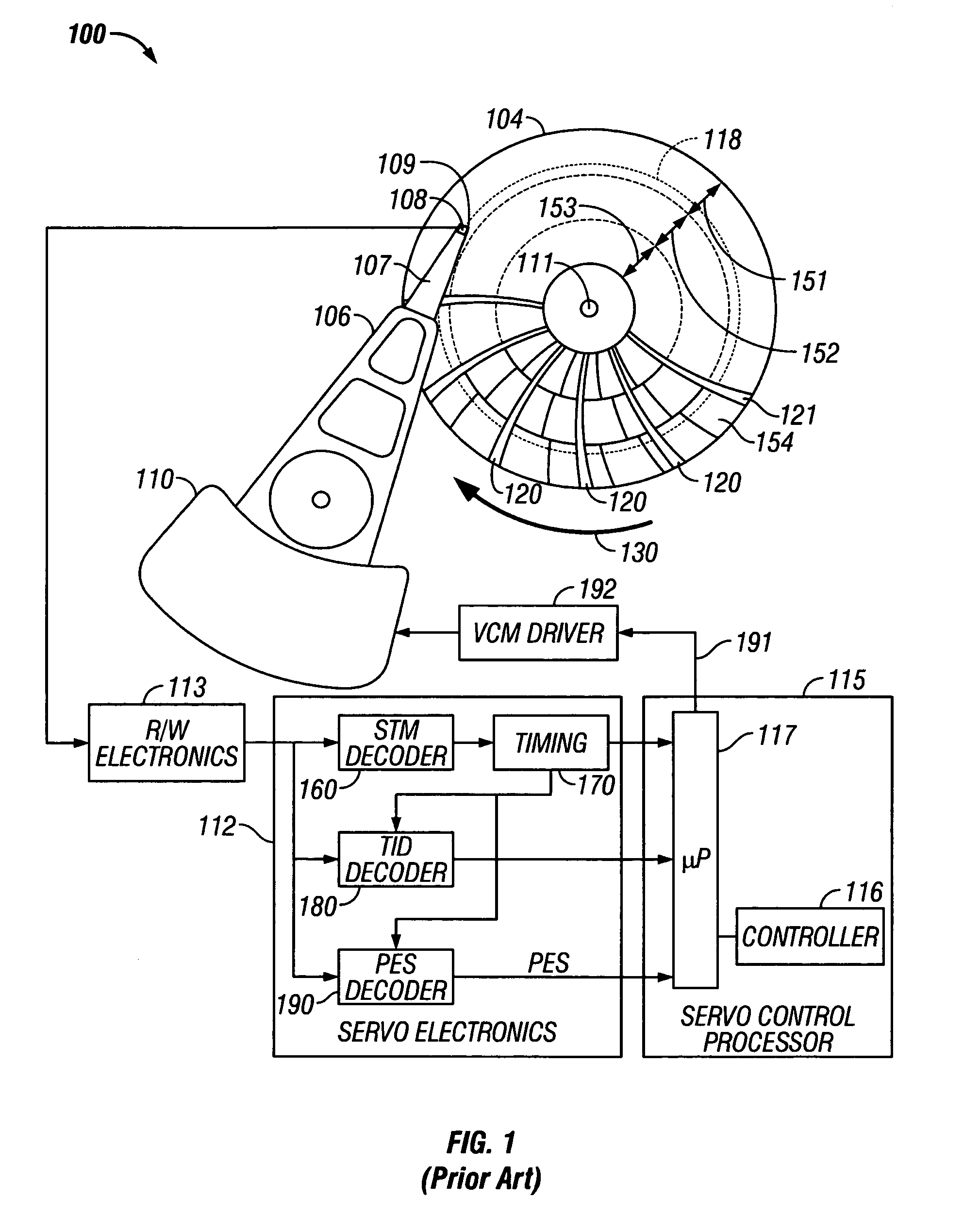

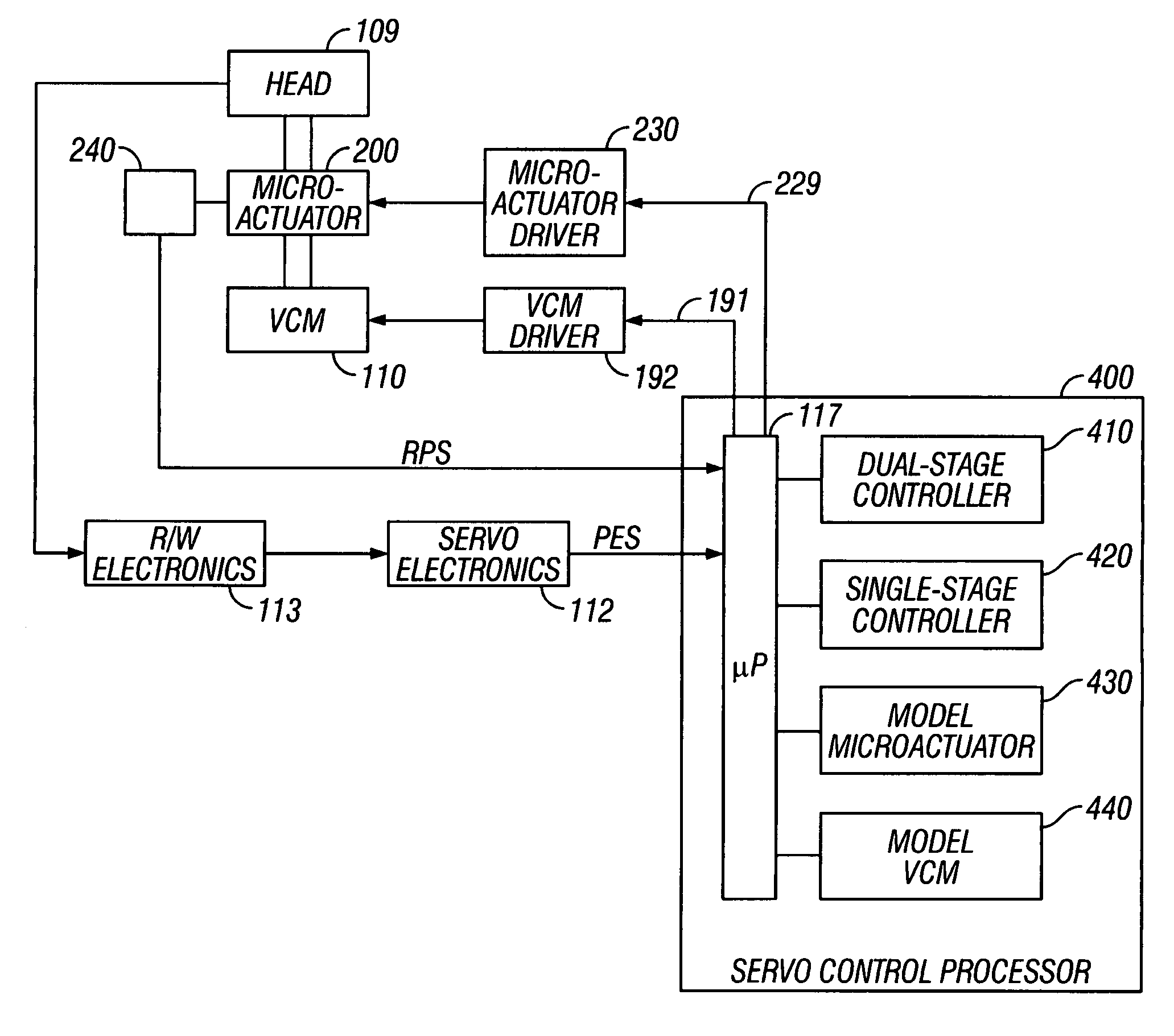

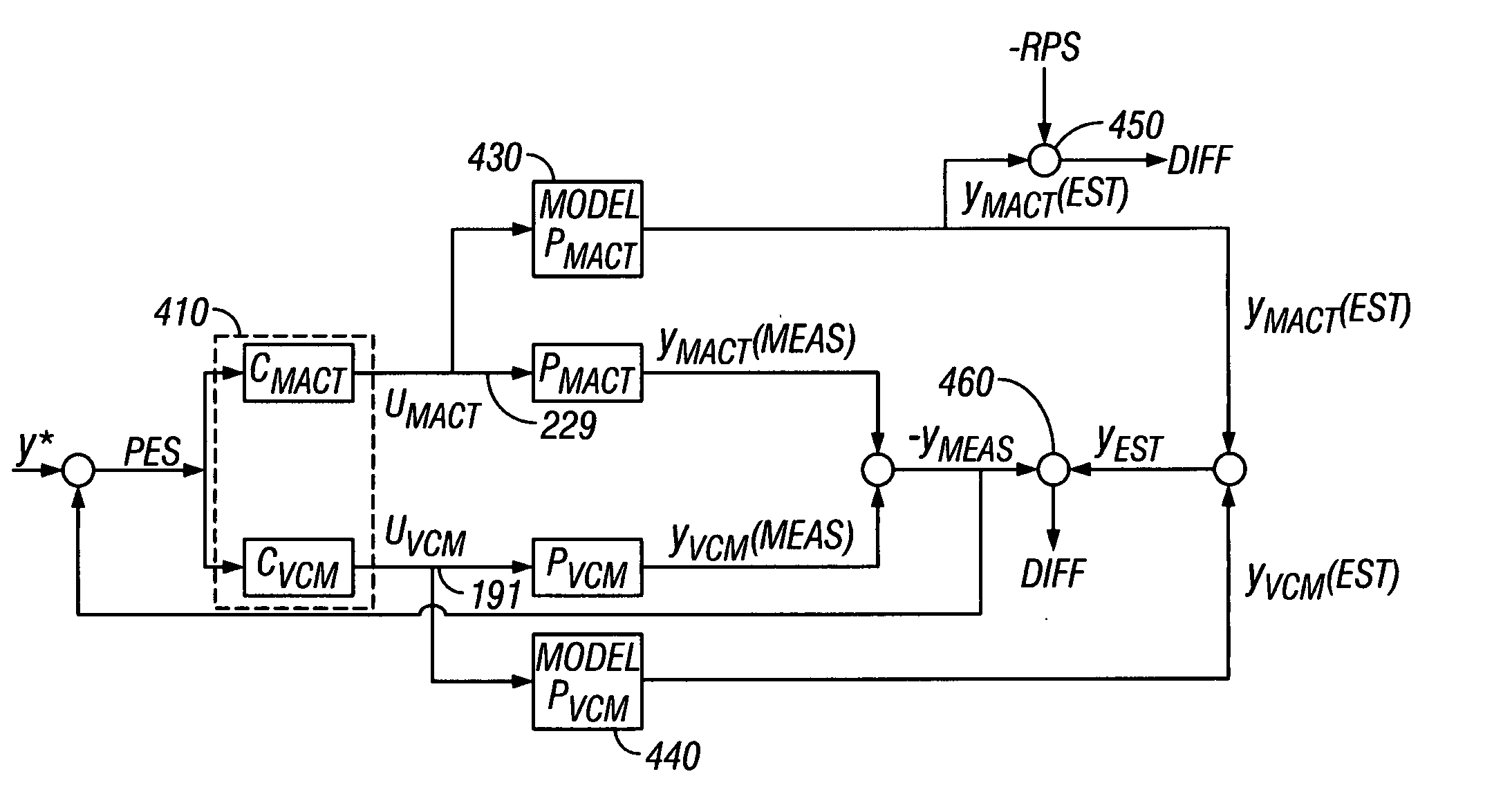

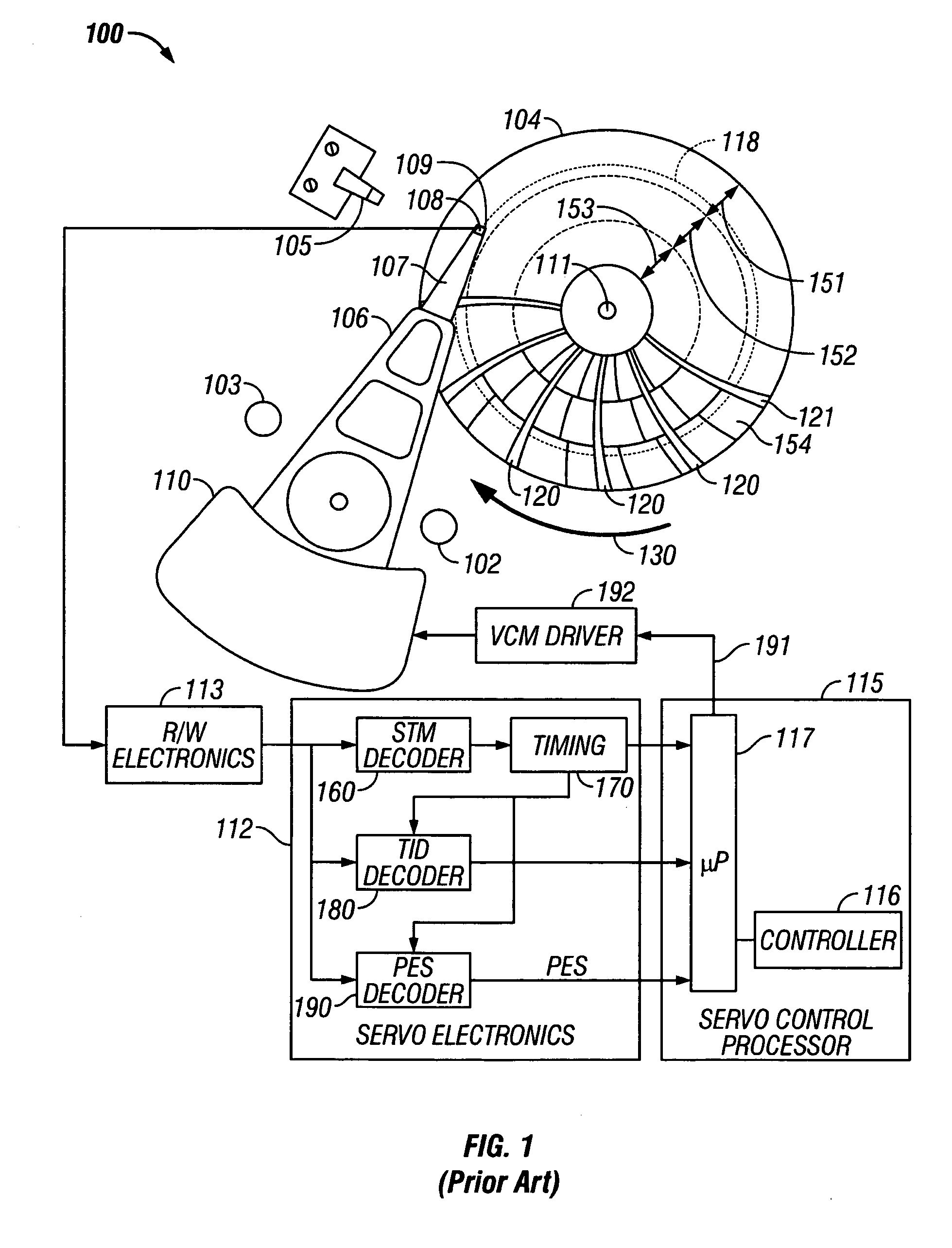

Method for secondary-actuator failure detection and recovery in a dual-stage actuator disk drive

InactiveUS7106552B2Record information storageAlignment for track following on disksDual stageActuator

A method for secondary-actuator failure-detection and recovery in a dual-stage actuator disk drive includes running a calibration test by the servo control processor and measuring the position of the secondary actuator relative to its neutral position in response to the calibration test. The secondary-actuator failure detection and calibration test can be performed on a regular schedule or at selected times, such as at disk drive start-up. With the primary actuator biased at a test location, such as a crash stop or a load / unload ramp, the servo control processor generates a test signal to the secondary actuator and receives a relative-position signal (RPS) from the relative-position sensor in response to the test signal. The test comprises two measurements: a measurement of the secondary actuator static characteristics, and a measurement of the secondary actuator dynamic characteristics.

Owner:WESTERN DIGITAL TECH INC

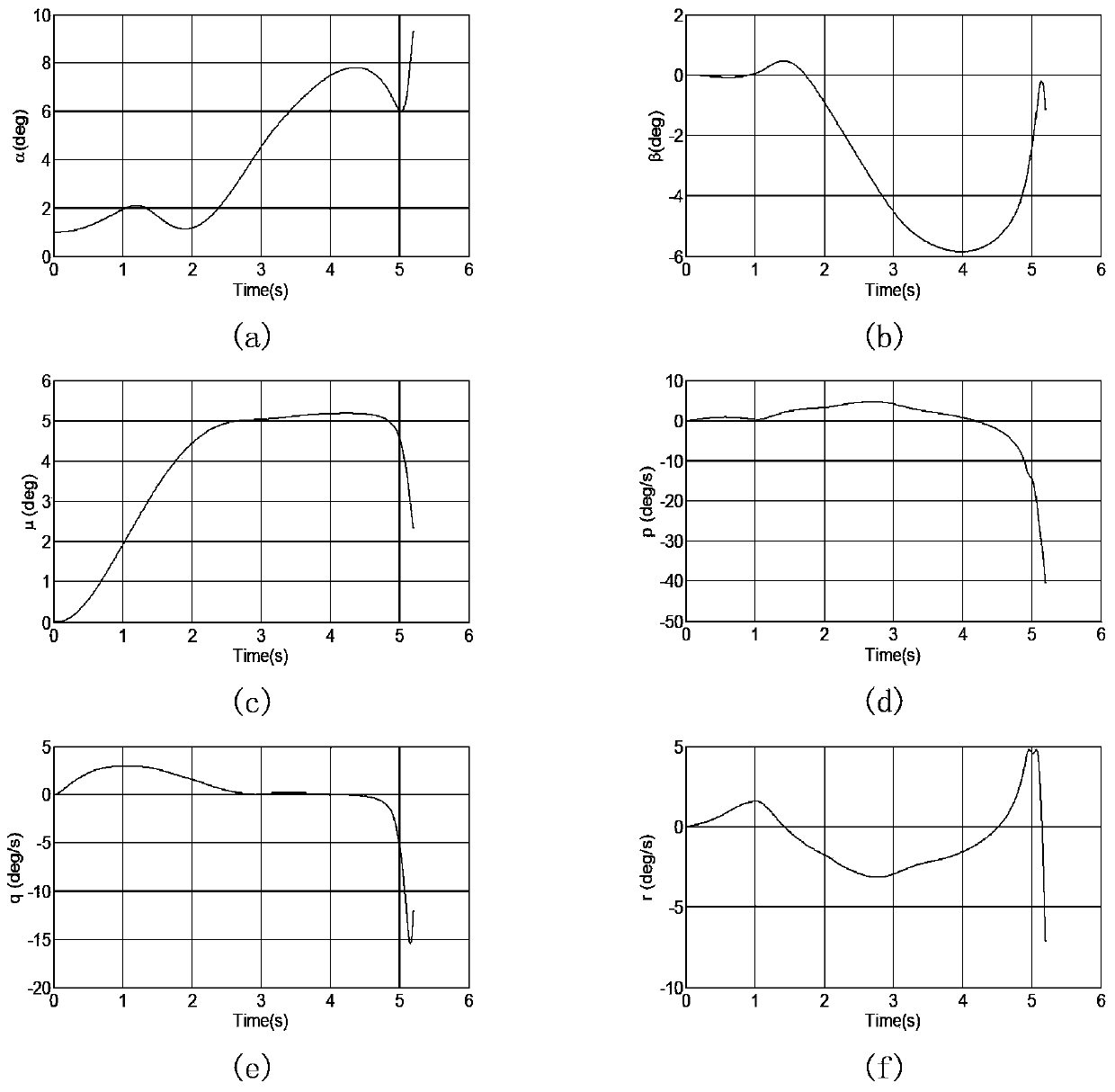

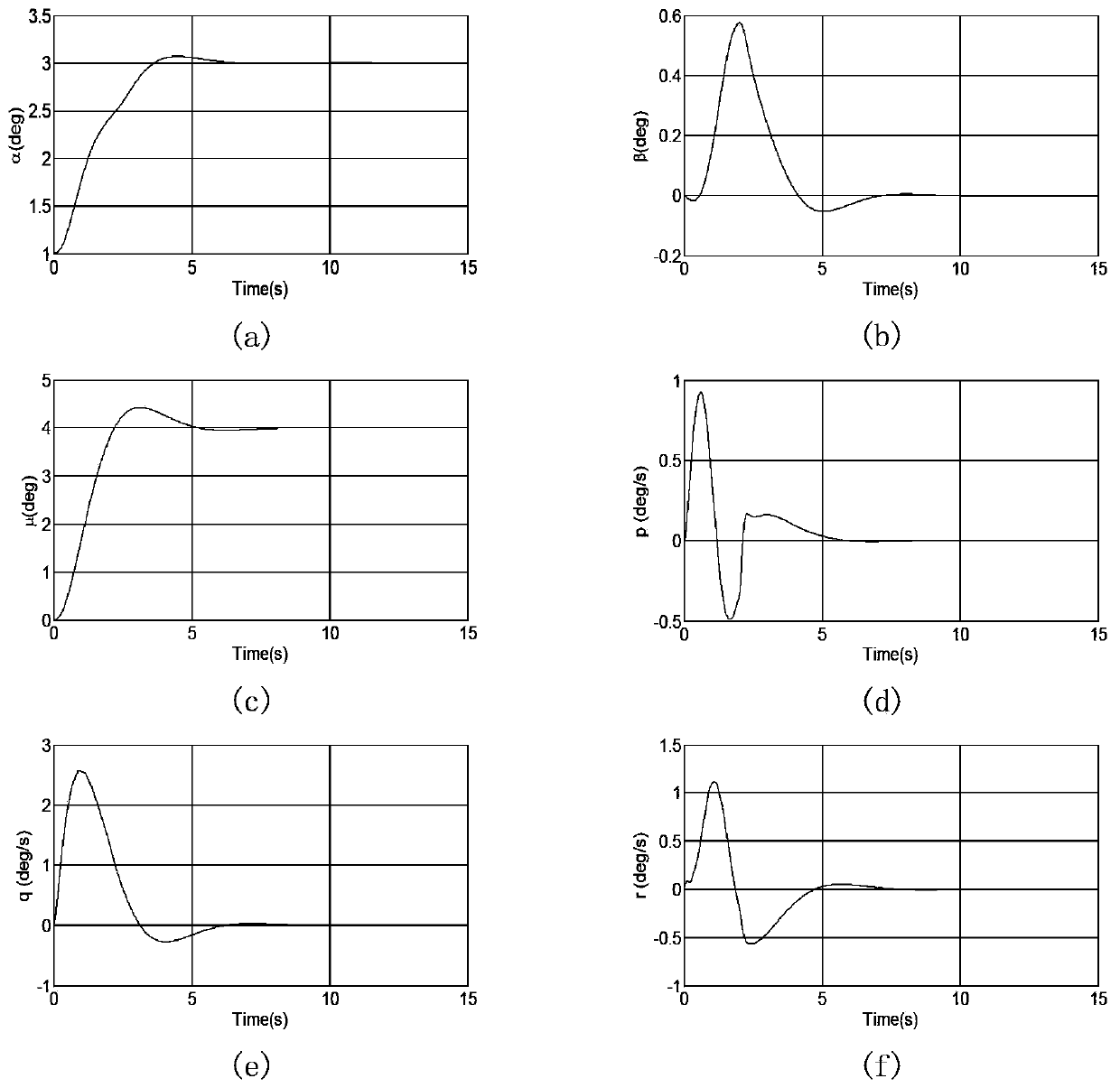

Unmanned aircraft posture decentralized fault-tolerant control method based on actuator dynamic state

The invention designs an actuator fault detection and identification unit based on multiple observers and a decentralized fault-tolerant control framework for a near space aircraft with disturbances and parameter uncertainty by considering the problem of robust fault-tolerant control after the aircraft has actuator and control surface faults. A system can acquire the fault information of an actuator in real time. A self-adaptive sliding mode observer is designed for an attitude angular velocity loop. A designed observer has strong robustness, does not need to know the upper bound of the uncertainty or the disturbances. The information of a control surface damage fault and the disturbance information are fully implied. A fault-tolerant controller is designed based on an observer model. Through a designed fault-tolerant control system, robust fault-tolerance control is realized under the conditions of various different types of faults and multiple faults. The designed method is respectively applied to posture stabilization control and tracking control of the near space aircraft in the presence of actuator and control surface faults, and flight posture robust fault-tolerant control is realized.

Owner:JINLING INST OF TECH

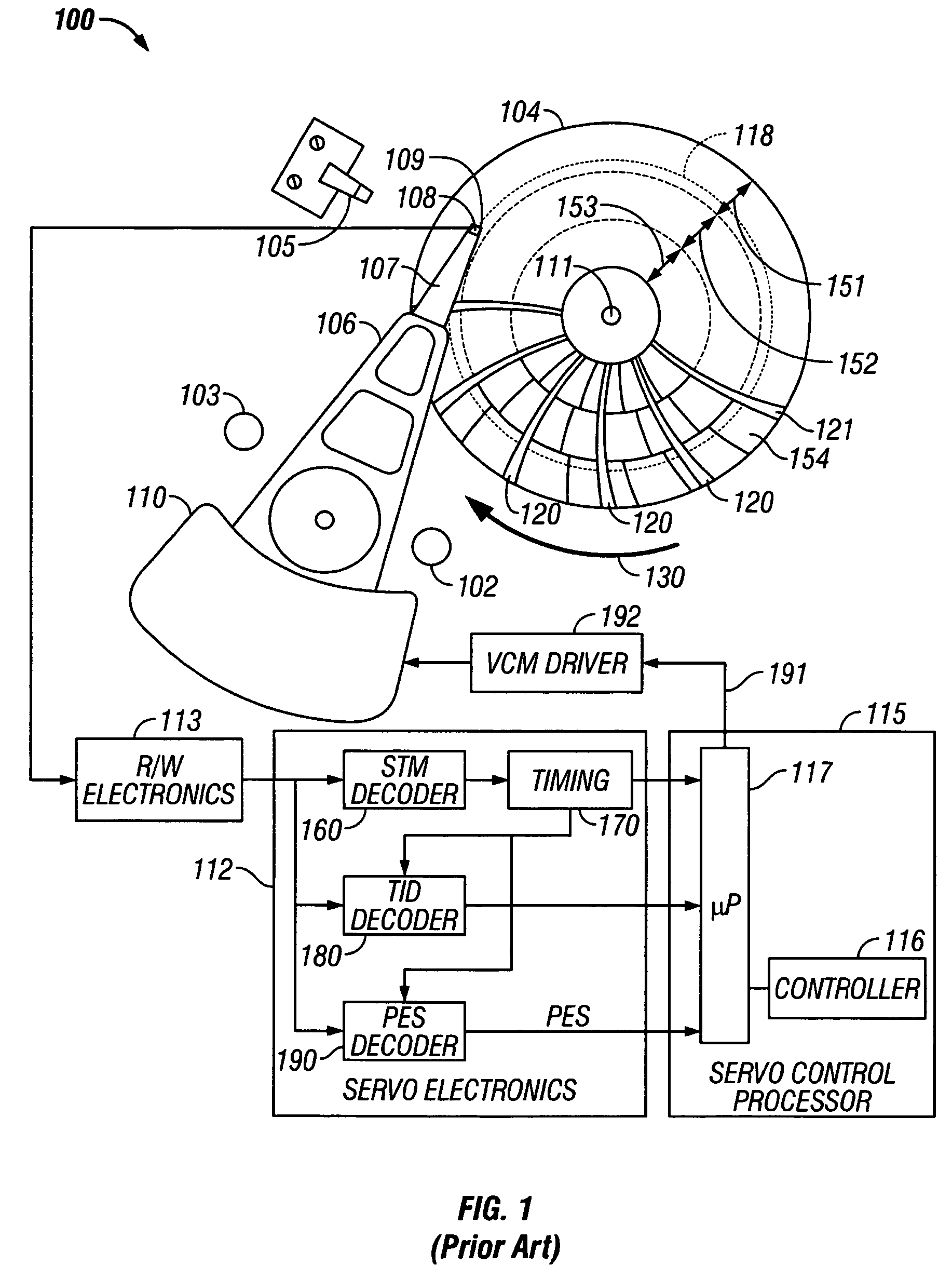

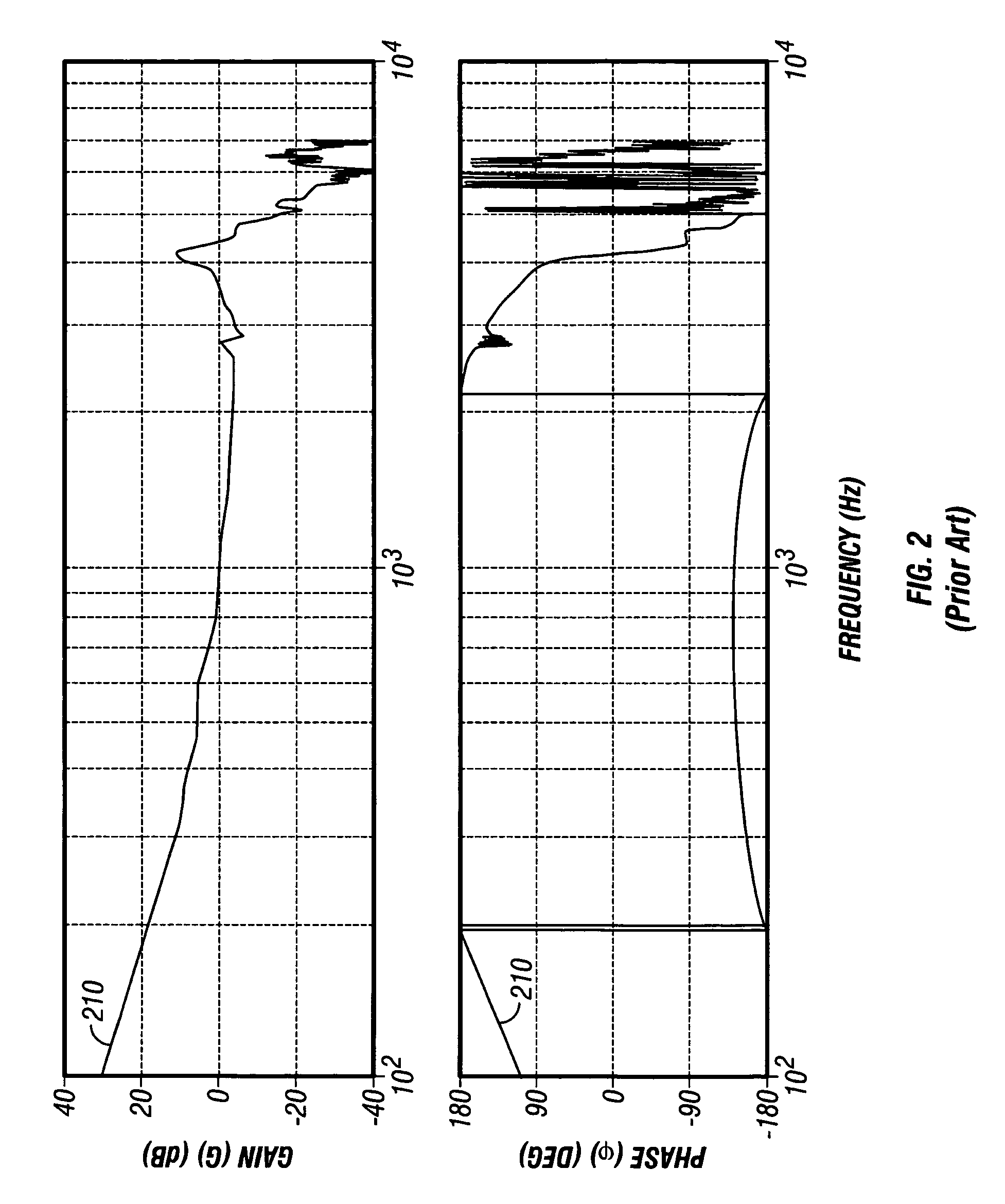

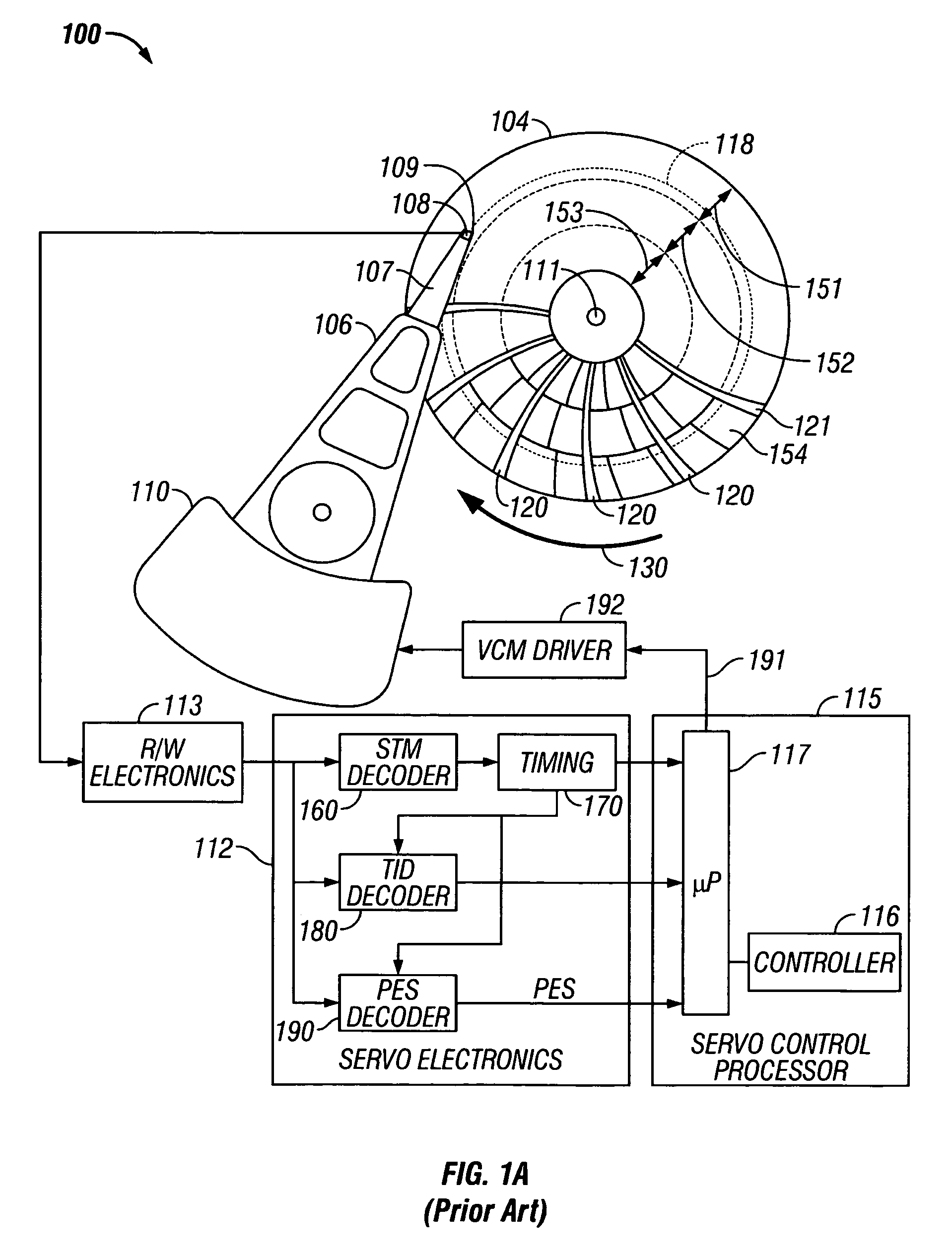

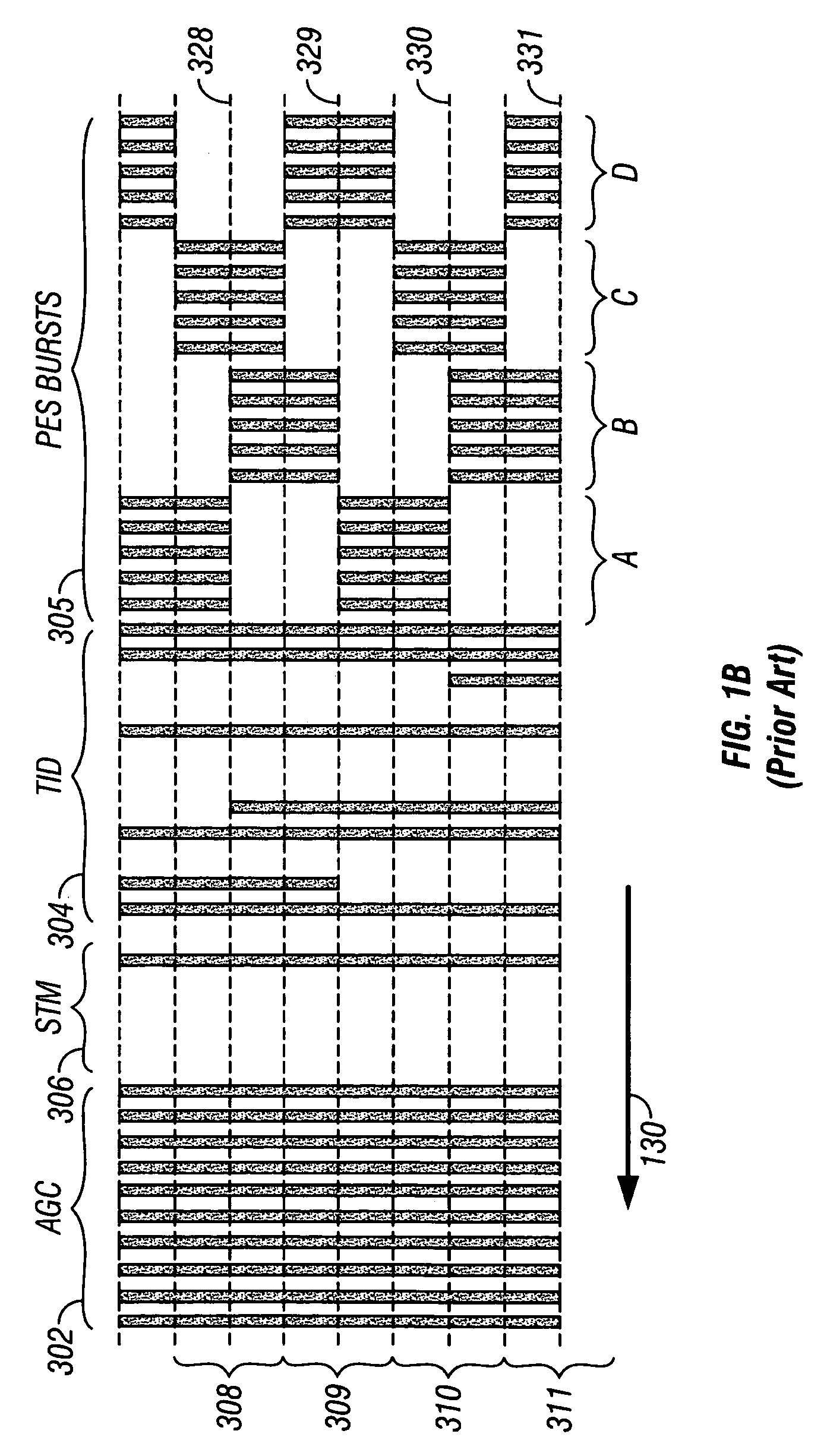

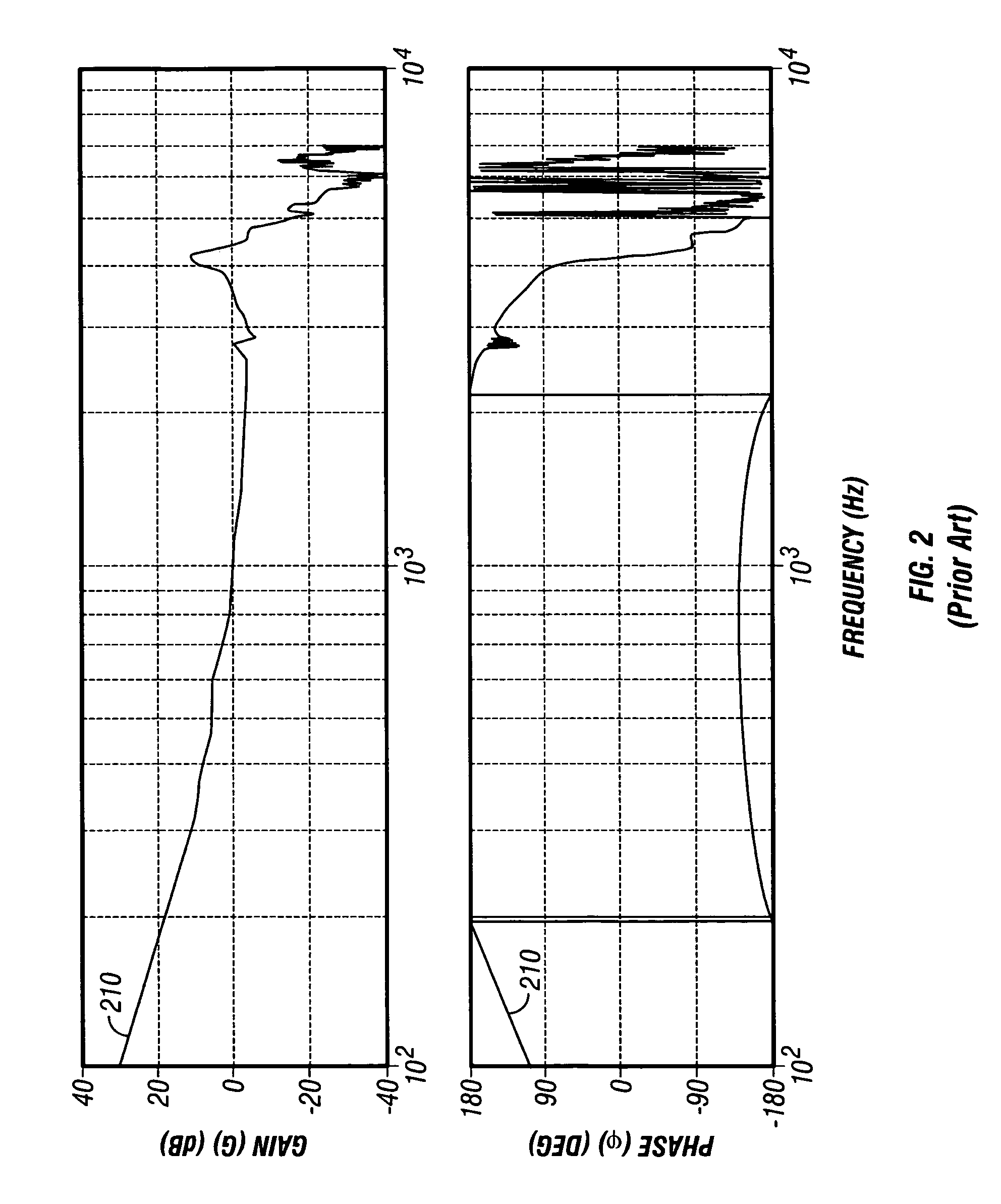

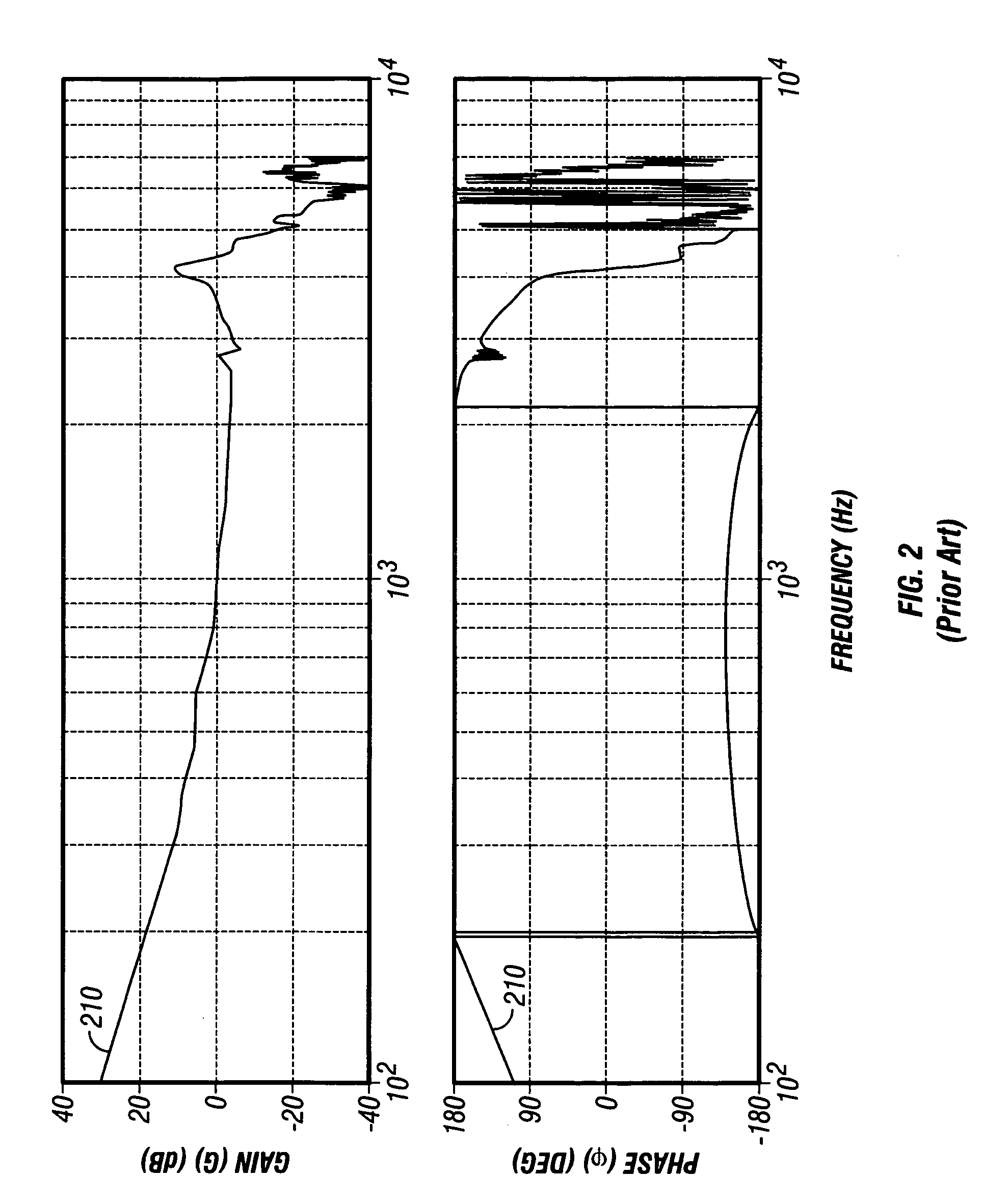

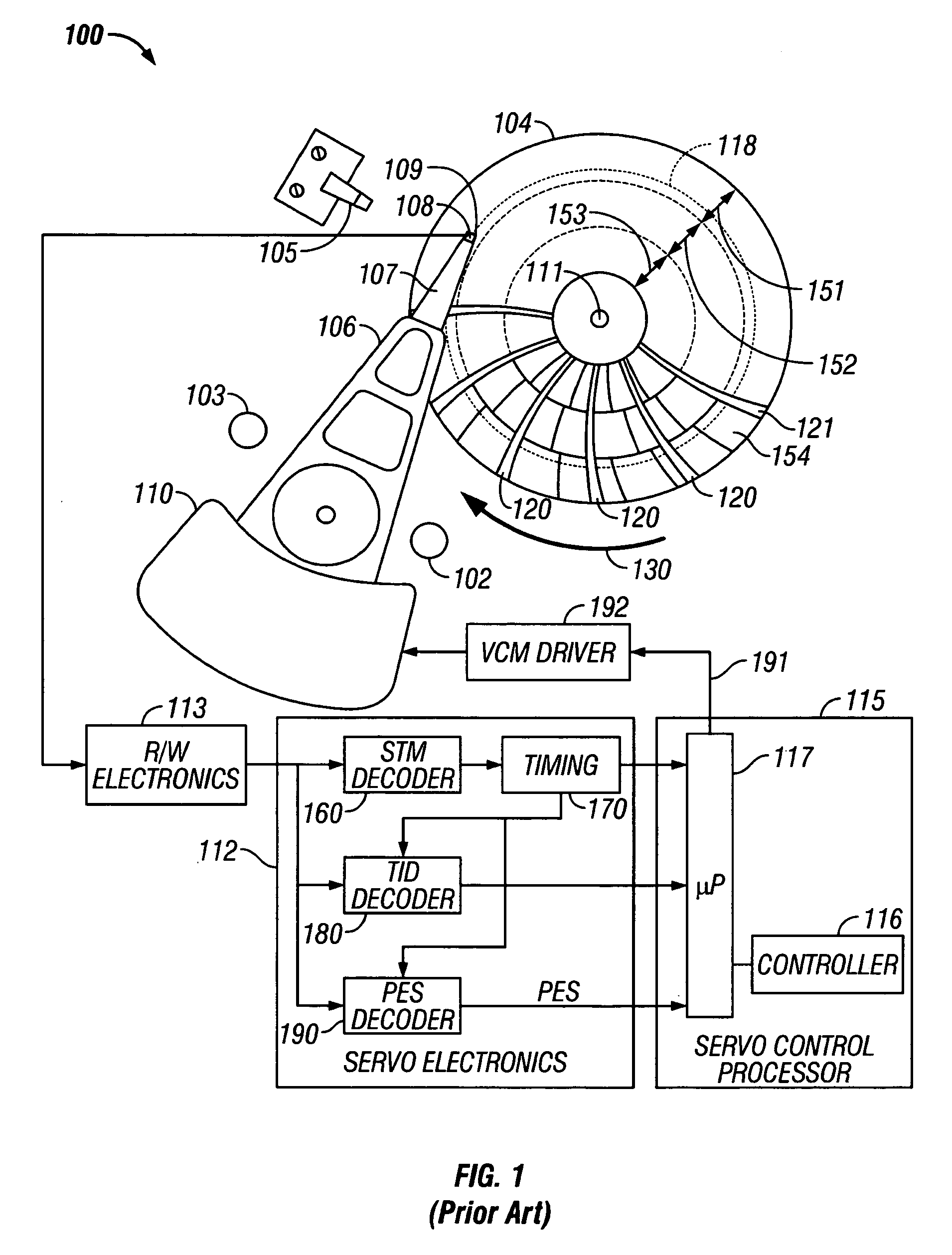

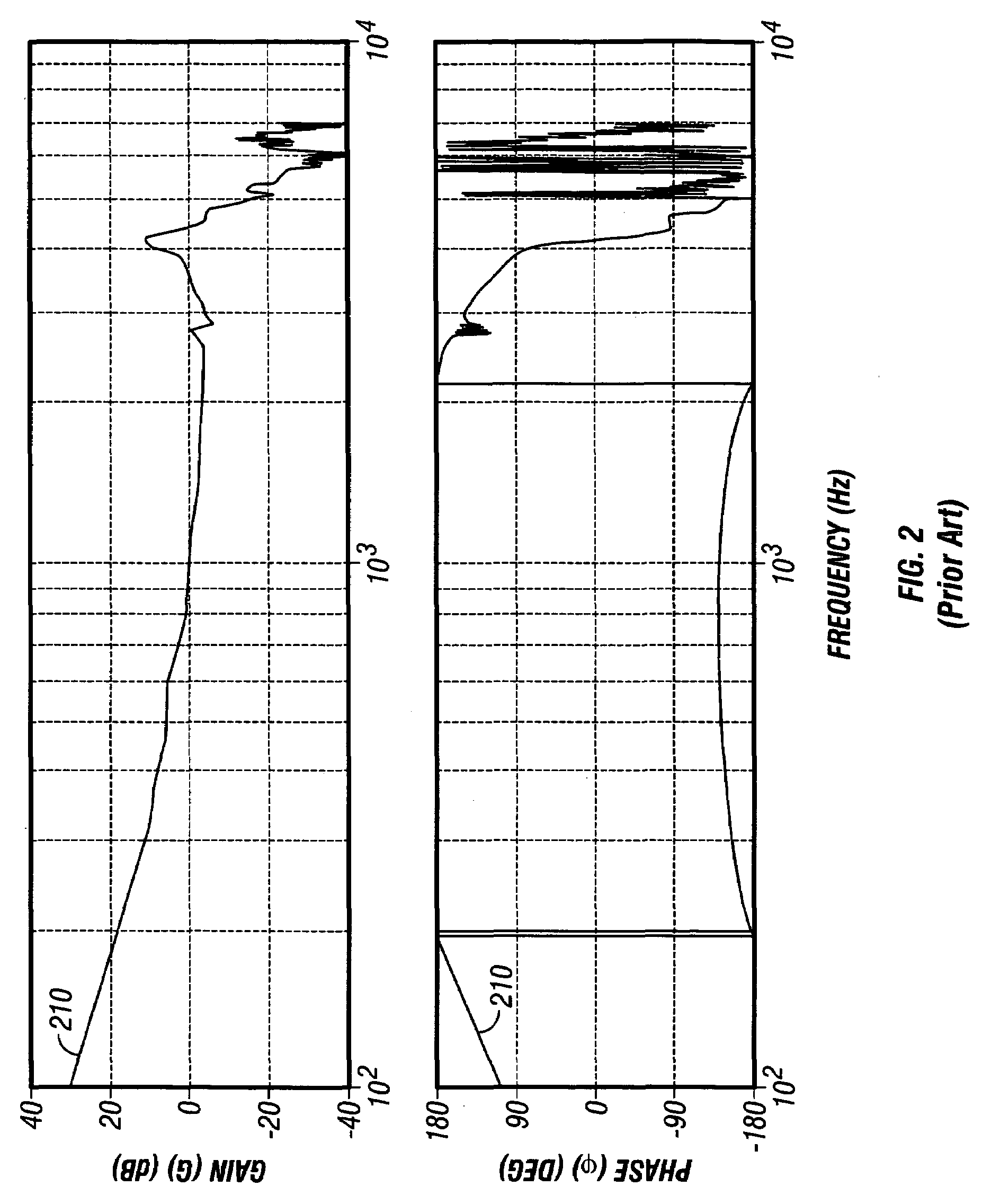

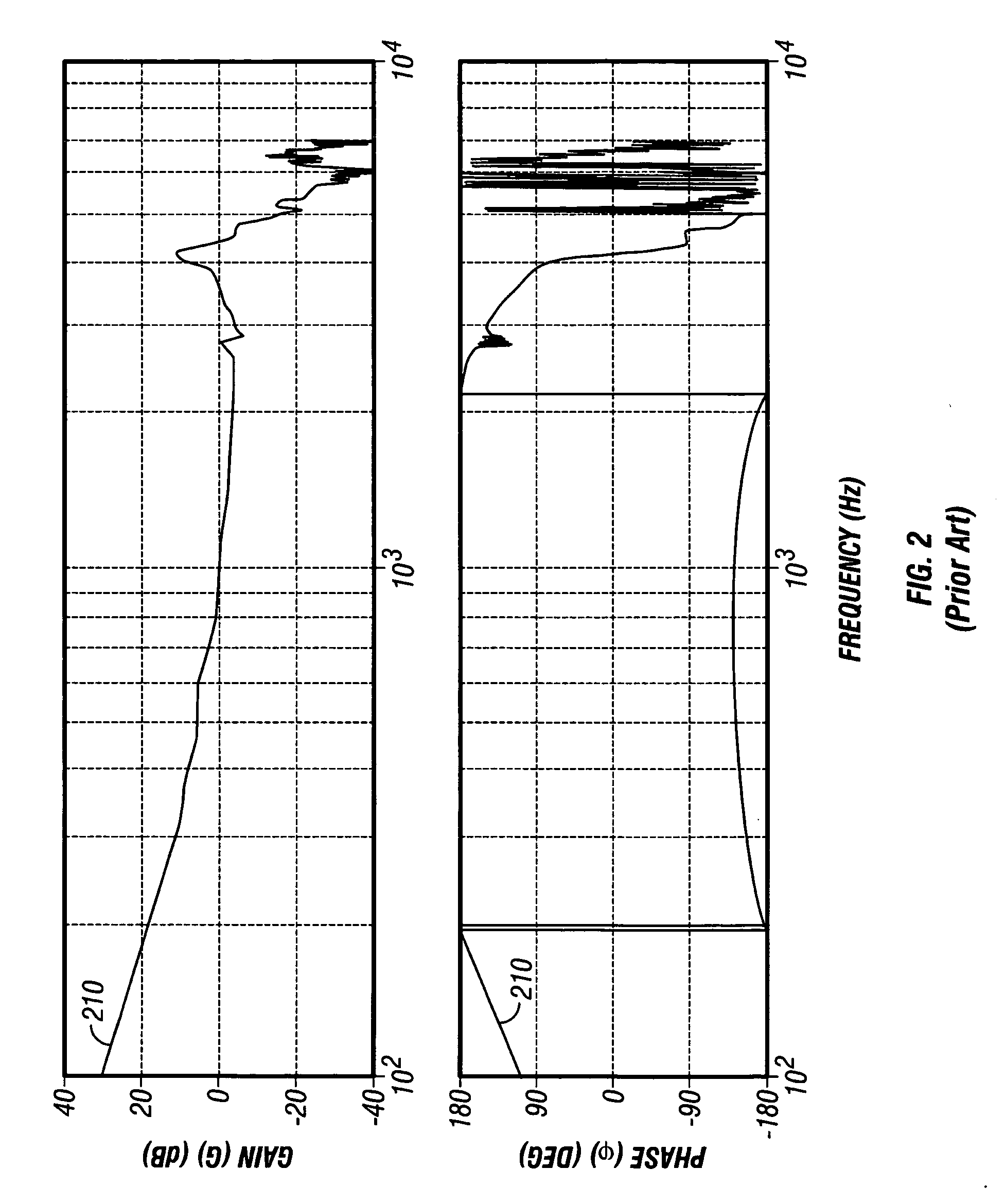

Dual-stage actuator disk drive with method for secondary-actuator failure detection and recovery while track-following

InactiveUS7079338B1Disc-shaped record carriersDriving/moving recording headsDual stageOperation mode

A method in a dual-stage actuator disk drive tests if the secondary actuator has failed while the disk drive is in its normal track-following operating mode. The secondary actuator is removed from the control loop and the primary actuator maintains the read / write head on a data track in the track-following mode. The servo control processor generates a test signal to the secondary actuator and receives the position error signal (PES) as the read head detects the PES bursts in the data track being followed. The servo control processor calculates the response of the secondary actuator to the test signal by deconvolving the motion of the primary actuator from the PES. The calculated response is then compared with an expected response to determine if the secondary actuator has failed. The coherence function can be calculated to measure the statistical validity of the calculated secondary-actuator frequency response.

Owner:WESTERN DIGITAL TECH INC

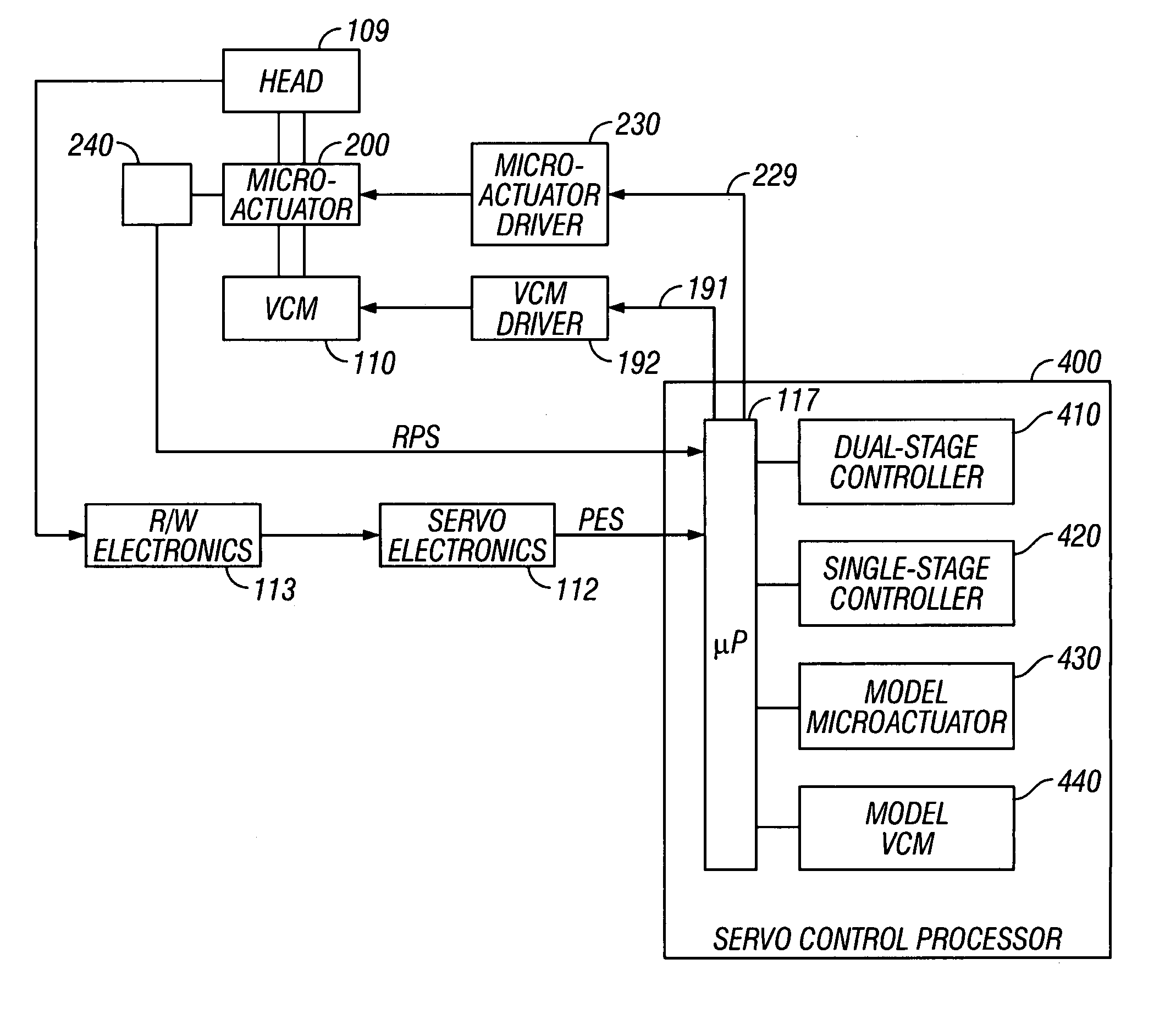

Disk drive with a dual-stage actuator and failure detection and recovery system for the secondary actuator

InactiveUS7075748B2Record information storageAlignment for track following on disksControl engineeringActuator fault detection

A dual-stage actuator disk drive has calibration tracks located in a nondata band, and uses a secondary-actuator failure detection and calibration test run by the servo control processor. The calibration tracks contain a pattern of pre-written magnetized test blocks. The test is run with the primary actuator biased against a crash stop, which enables the read head to access the calibration tracks. The servo control processor generates a test signal to the secondary actuator and receives a calibration signal from the read head as the read head detects the test blocks in the calibration tracks. The test comprises two measurements: a measurement of the secondary actuator static characteristics, and a measurement of the secondary actuator dynamic characteristics.

Owner:WESTERN DIGITAL TECH INC

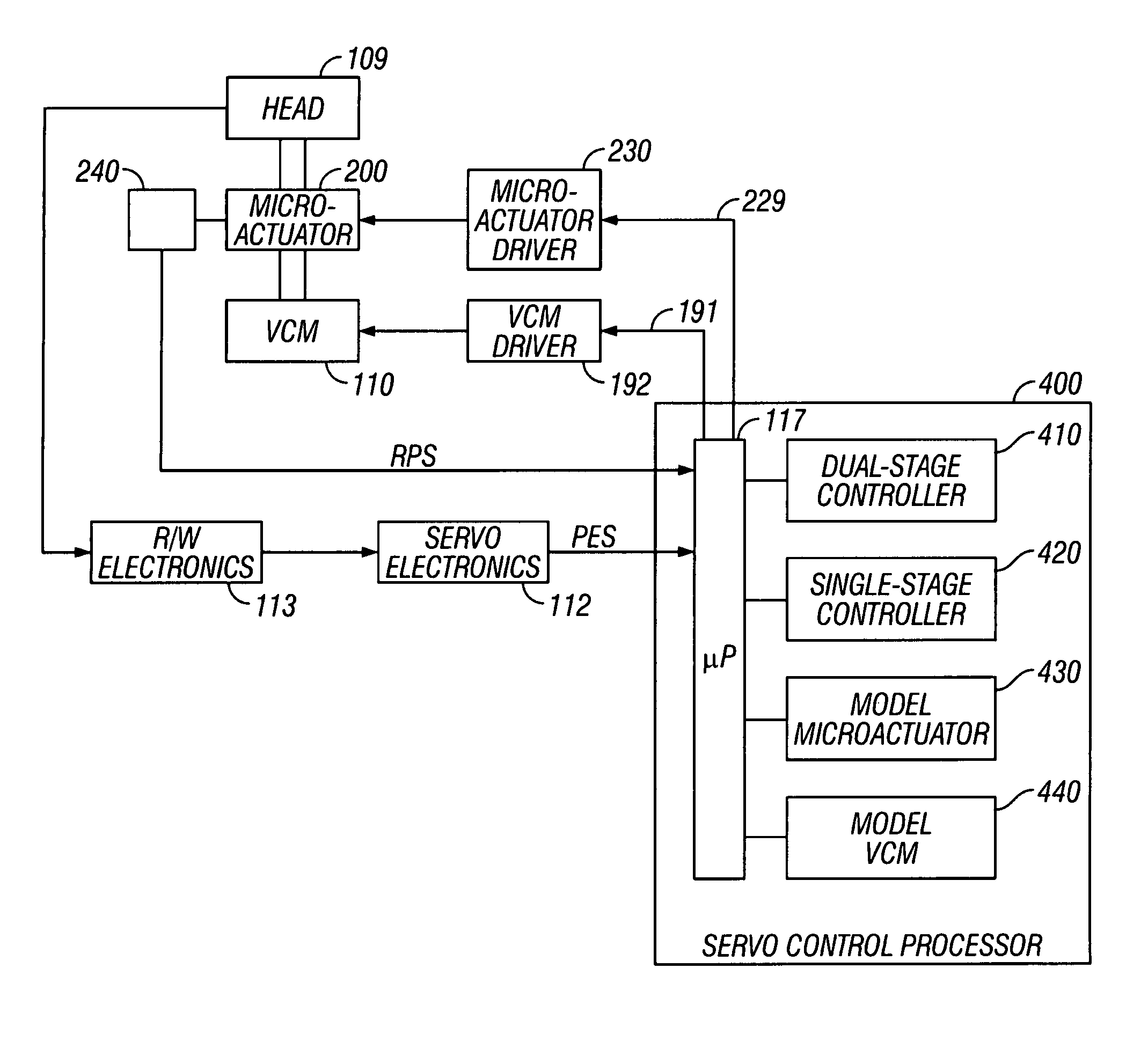

Dual-stage actuator disk drive with method for secondary-actuator failure detection and recovery using a relative-position sensor while track following

A method for secondary-actuator failure-detection and recovery in a dual-stage actuator disk drive includes running a calibration test by the servo control processor and measuring the position of the secondary actuator relative to its neutral position in response to the calibration test. The secondary-actuator failure detection and calibration test can be performed on a regular schedule or at selected times, such as at disk drive start-up. With the primary actuator maintaining the read / write head on a data track in track-following mode, the servo control processor generates a test signal to the secondary actuator and receives a relative-position signal (RPS) from the relative-position sensor in response to the test signal. The test comprises two measurements: a measurement of the secondary actuator static characteristics, and a measurement of the secondary actuator dynamic characteristics.

Owner:WESTERN DIGITAL TECH INC

Dual-stage actuator disk drive with secondary actuator failure detection and recovery using relative-position signal

InactiveUS7072134B1Record information storageRecording/reproducing/erasing methodsDual stageActuator fault detection

A dual-stage actuator disk drive uses a secondary-actuator failure-detection and calibration test run by the servo control processor and a relative-position sensor for measuring the position of the secondary actuator relative to its neutral position in response to the calibration test. The secondary-actuator failure detection and calibration test can be performed on a regular schedule or at selected times, such as at disk drive start-up. With the primary actuator biased at a test location, such as a crash stop or a load / unload ramp, the servo control processor generates a test signal to the secondary actuator and receives a relative-position signal (RPS) from the relative-position sensor in response to the test signal. The test comprises two measurements: a measurement of the secondary actuator static characteristics, and a measurement of the secondary actuator dynamic characteristics.

Owner:WESTERN DIGITAL TECH INC

Method for secondary-actuator failure detection and recovery in a dual-stage actuator disk drive

InactiveUS20060171062A1Record information storageAlignment for track following on disksSignal responseDual stage

A method for secondary-actuator failure-detection and recovery in a dual-stage actuator disk drive includes running a calibration test by the servo control processor and measuring the position of the secondary actuator relative to its neutral position in response to the calibration test. The secondary-actuator failure detection and calibration test can be performed on a regular schedule or at selected times, such as at disk drive start-up. With the primary actuator biased at a test location, such as a crash stop or a load / unload ramp, the servo control processor generates a test signal to the secondary actuator and receives a relative-position signal (RPS) from the relative-position sensor in response to the test signal. The test comprises two measurements: a measurement of the secondary actuator static characteristics, and a measurement of the secondary actuator dynamic characteristics.

Owner:WESTERN DIGITAL TECH INC

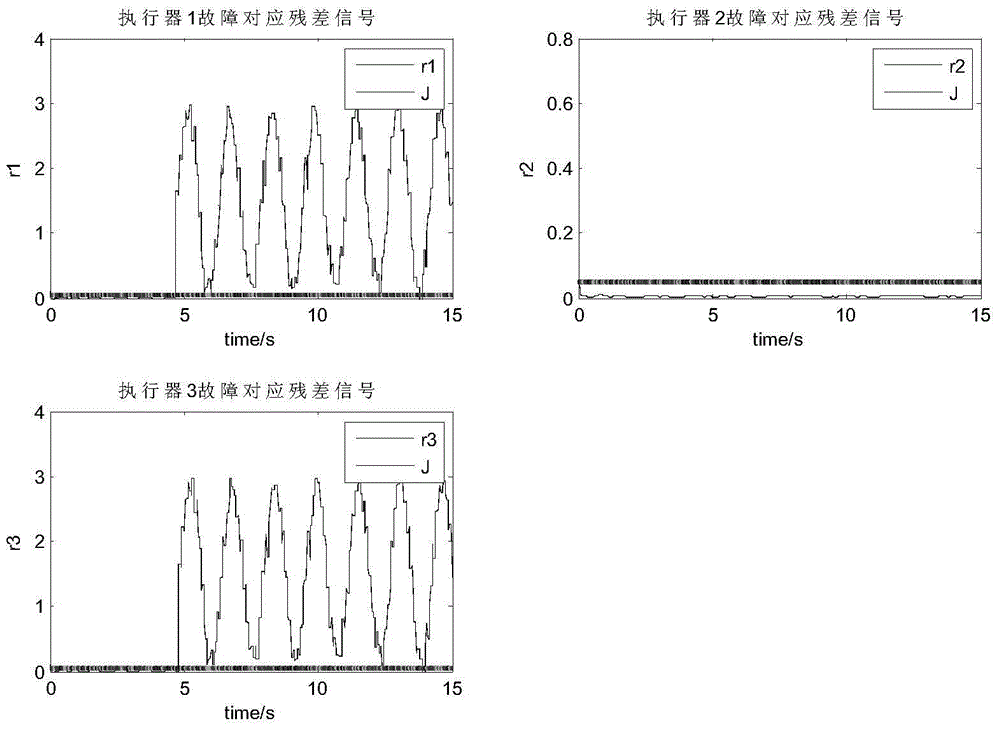

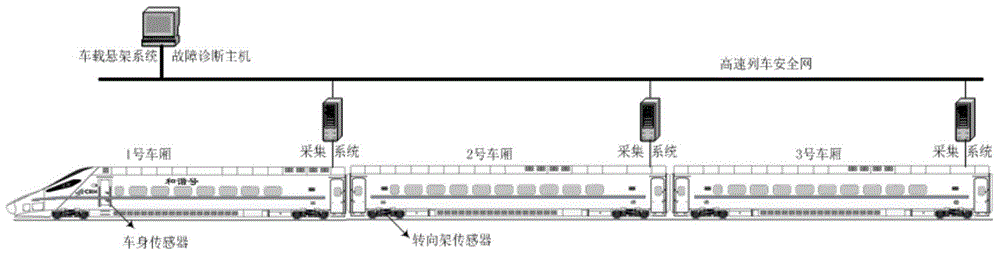

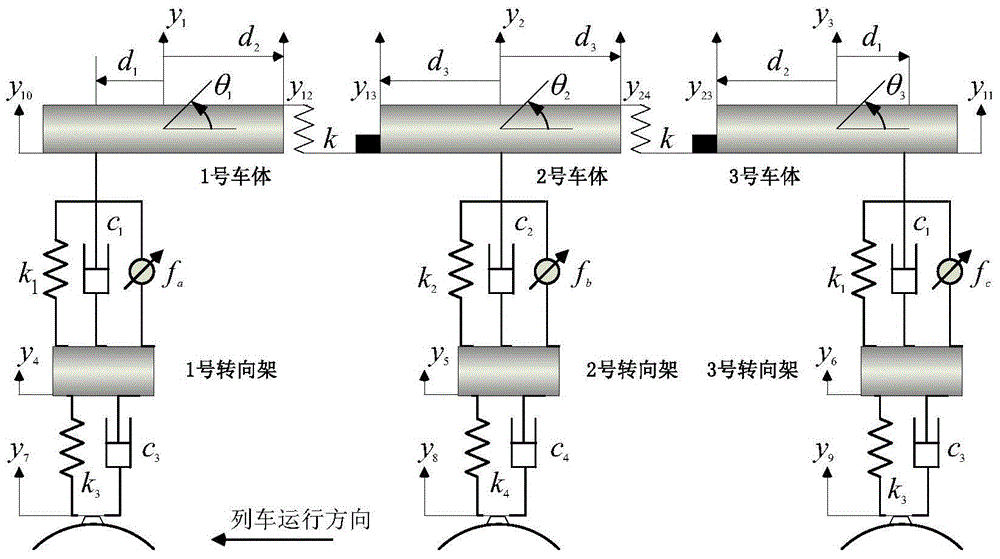

Multi-model-based high speed train suspension system multi-actuator fault detection and isolation method

ActiveCN104458298AImprove reliabilityEasy to checkRailway vehicle testingSystem maintenanceActuator fault detection

The invention provides a multi-model-based high speed train suspension system multi-actuator fault detection and isolation method. The method involves a first bullet train, a trailer and a second bullet train and comprises the following steps that (1) a suspension system, of a two-bullet-train and one-trailer structure, of a train is modeled to obtain a suspension system model; (2) a fault model is built for each actuator of the suspension system of the two-bullet-train and one-trailer structure; (3) a sliding-mode observer matched with each fault model is arranged based on the corresponding fault model, and the corresponding residual quantity is generated; (4) a fault warning threshold value is generated according to the train operating environment and suspension system working conditions, and a logic controller is used for decision making for all residual quantities to judge whether an alarm needs to be given out or not and point out the fault occurrence position. The application of the fault detection and isolation technology is the effective way for improving the system reliability, and an alarm is given in time when a fault occurs, particularly, the fault occurrence position is pointed out when the multiple actuators break down, and fault screening and system maintenance are facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fault detection system for actuator

ActiveUS9891135B2Easy to detectImprove maintainabilityMachine part testingFluid-pressure actuator testingEngineeringActuator fault detection

A failure detecting device of a fault detection system includes a detection time calculator, which calculates a stroke time T3 required for a piston to travel between one end and another end of an actuator based on detection signals from a first sensor and a second sensor, a statistical processor that performs a predetermined statistical calculation with respect to the stroke time T3, and a fault response detector, which detects whether or not a fault of the actuator has occurred based on a processing result of the statistical processor.

Owner:SMC CORP

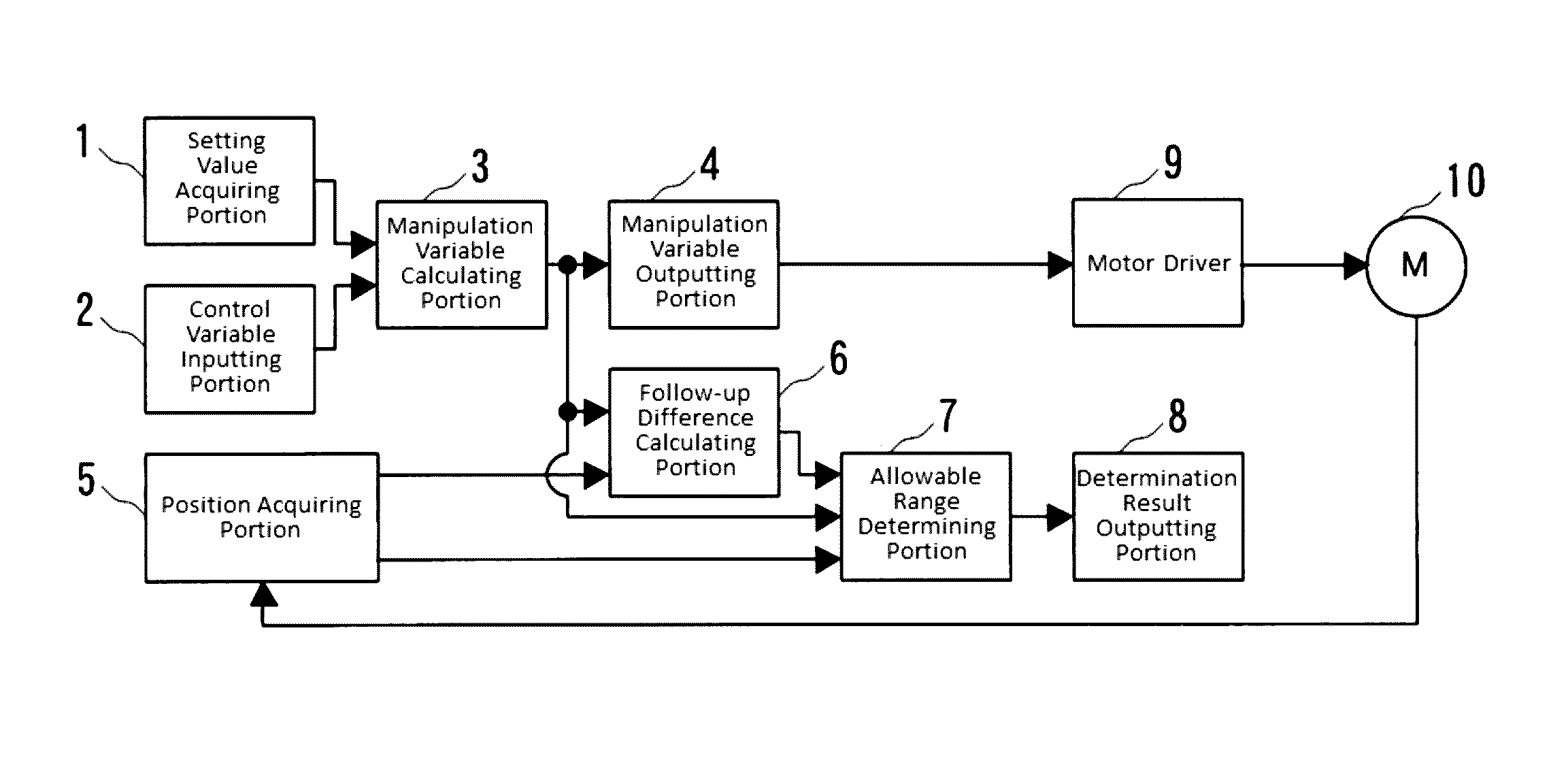

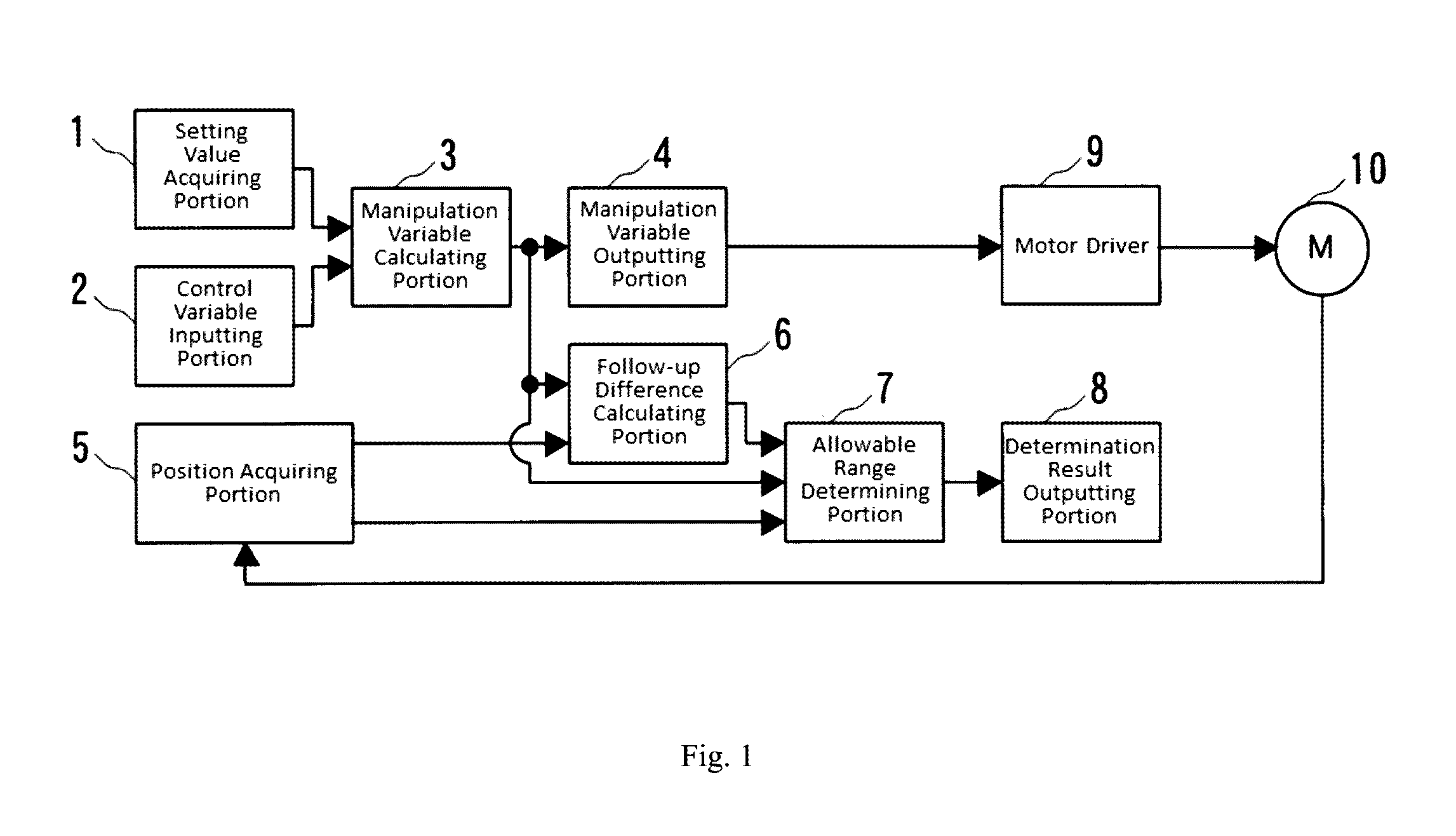

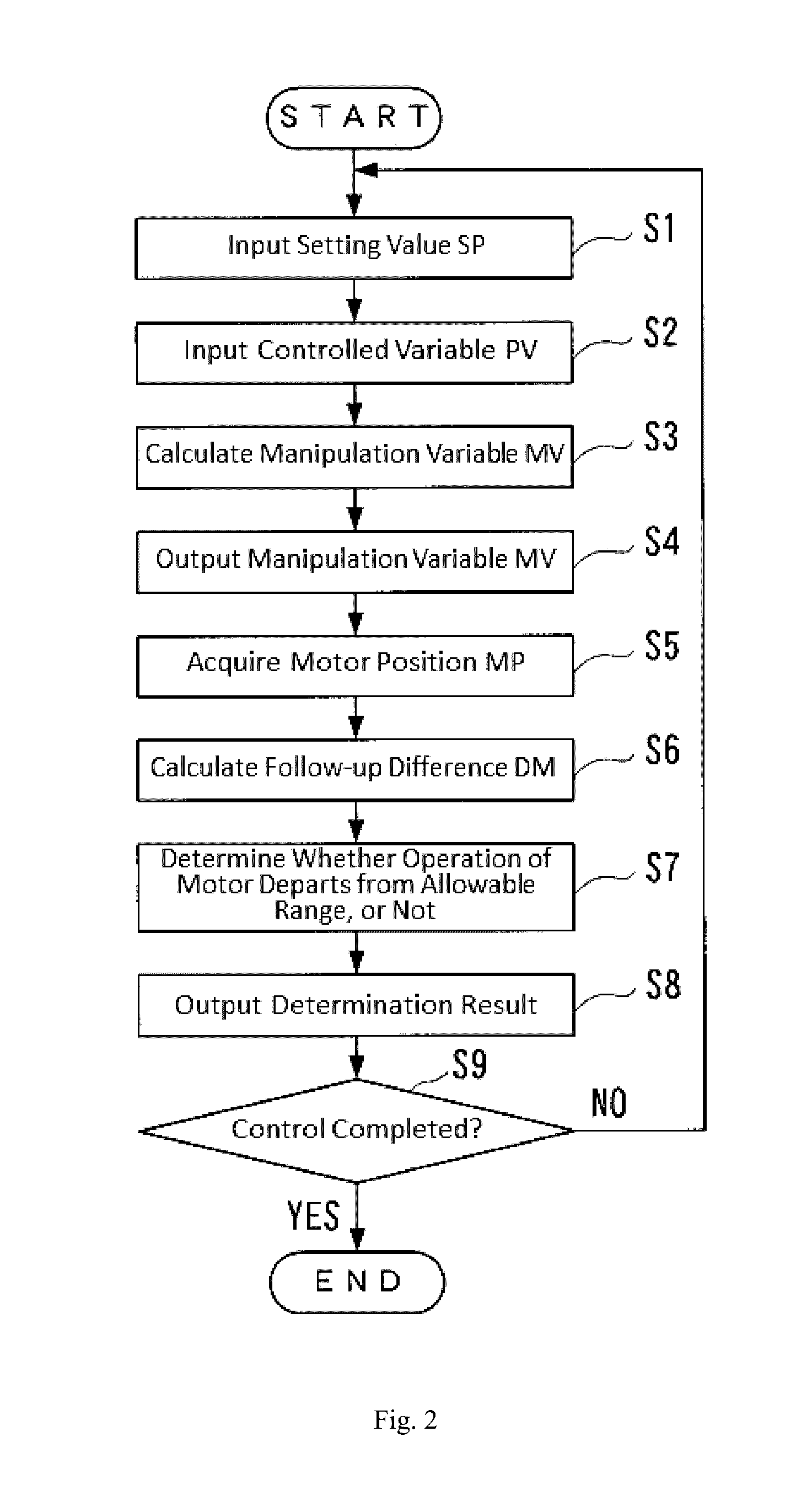

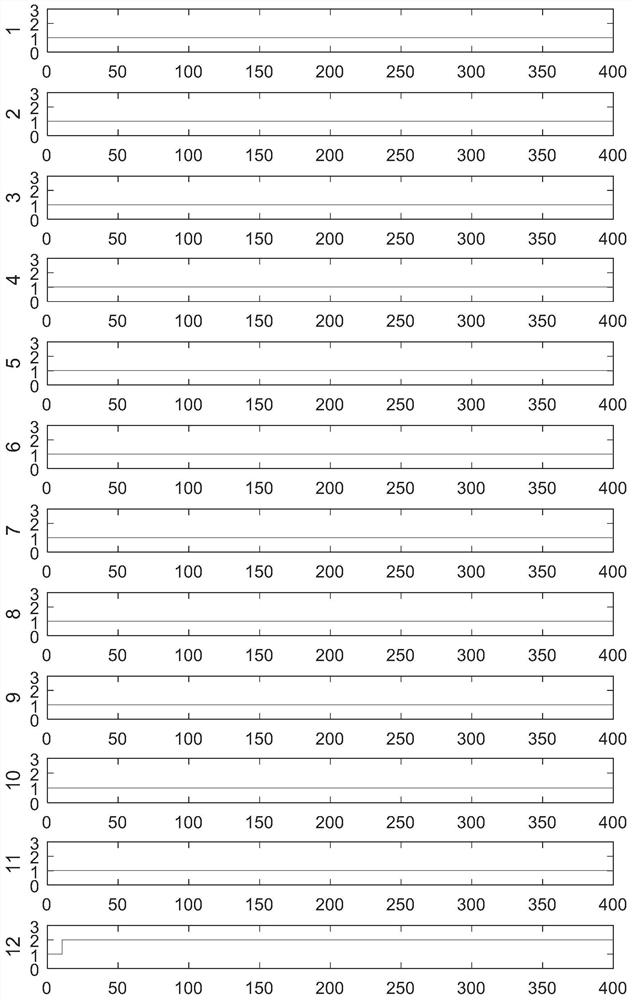

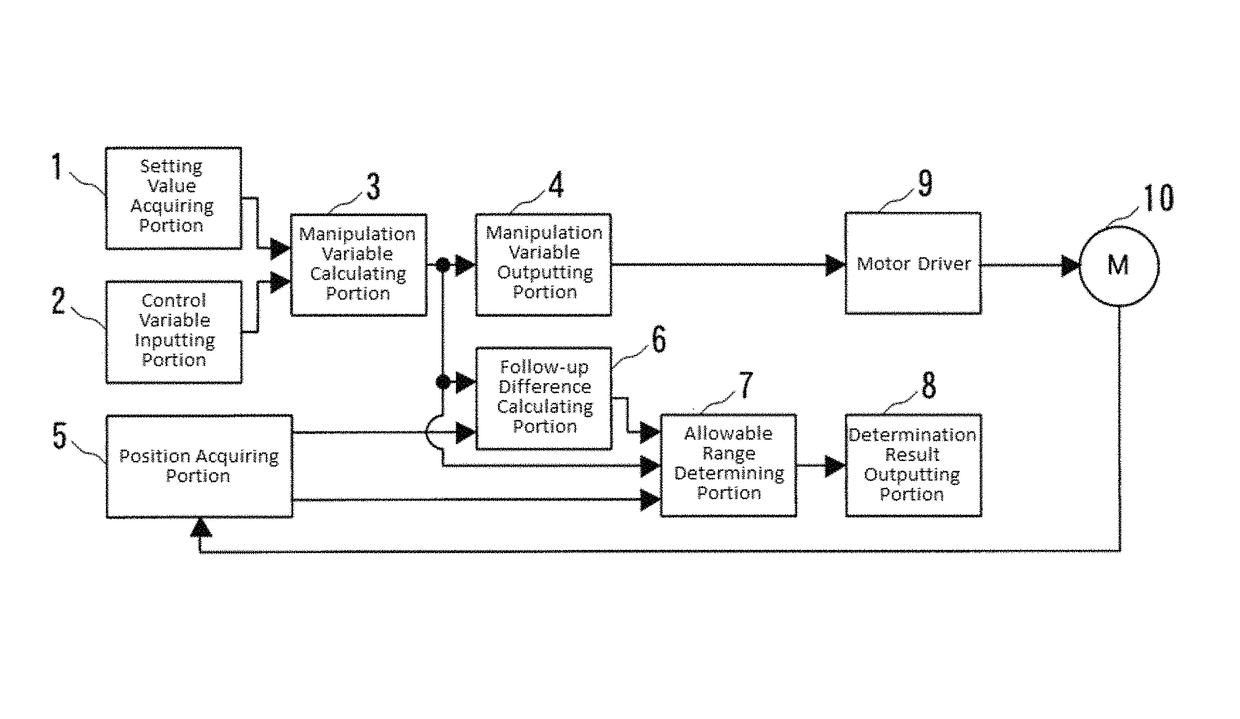

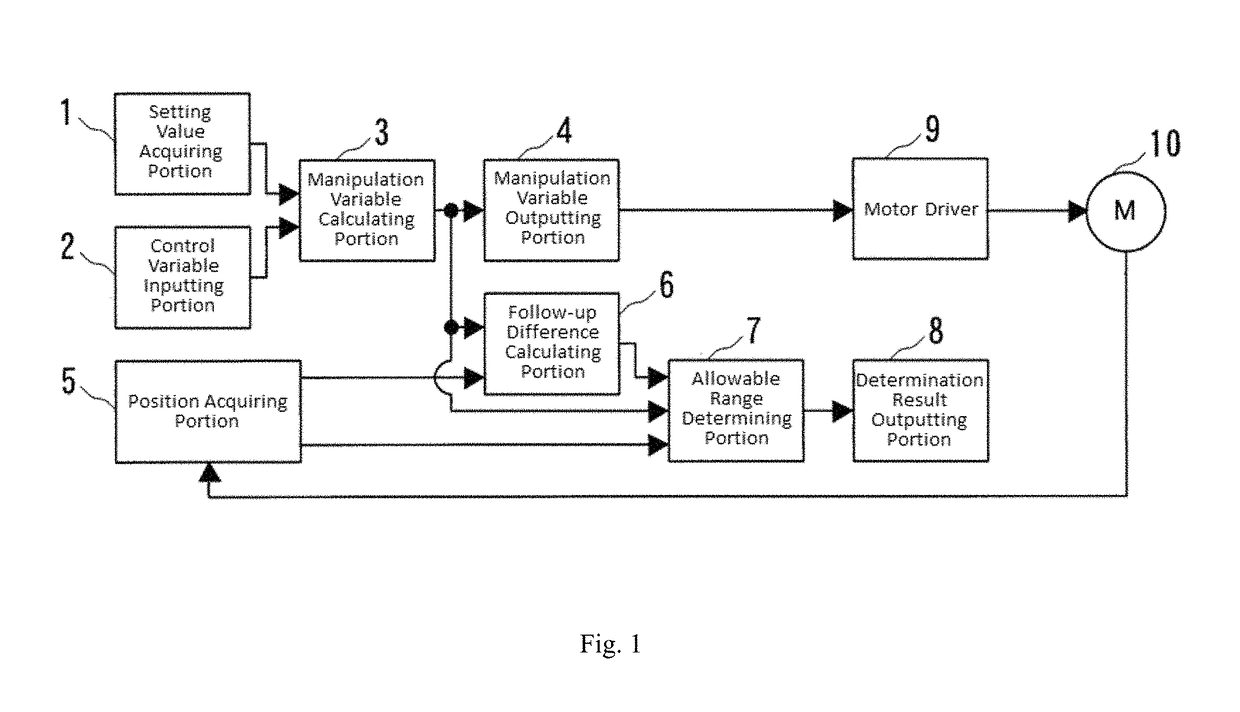

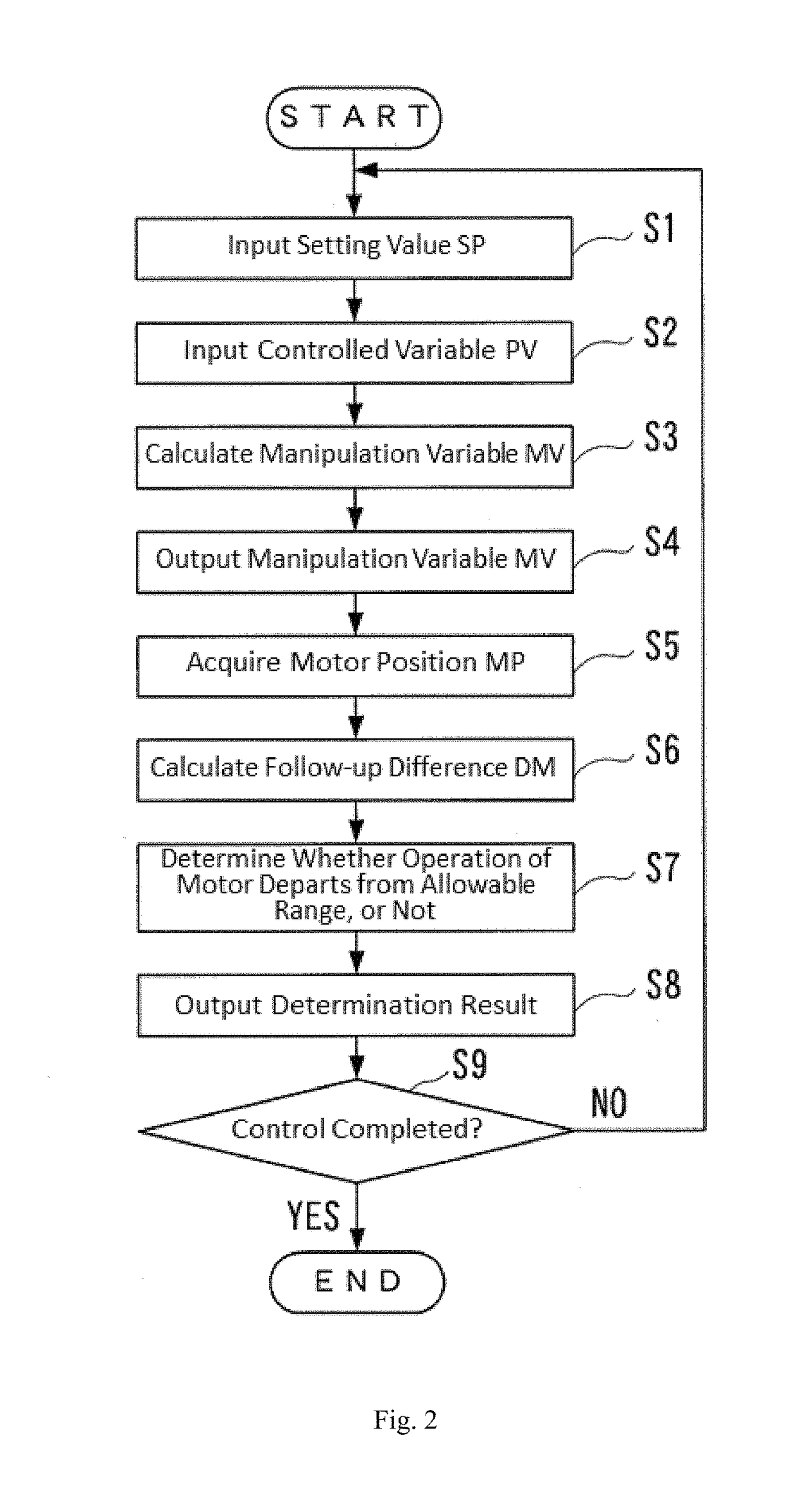

Actuator fault detection device, controlling device and control method

An actuator fault detection device that detects a fault of an actuator driven according to a manipulation variable MV output from a controlling device, including: a position acquiring portion that acquires a value of a motor position MP from a detector that detects a position of an actuator corresponding to a manipulation variable MV; a follow-up difference calculating portion that calculates a follow-up difference DM=MV−MP; and an allowable range determining portion that determines whether or not high speed operation or low speed operation of the actuator departs from an allowable range based on a manipulation variable change rate ΔMV, an actuator position change rate ΔMP, and the follow-up difference DM.

Owner:YAMATAKE HONEYWELL CO LTD

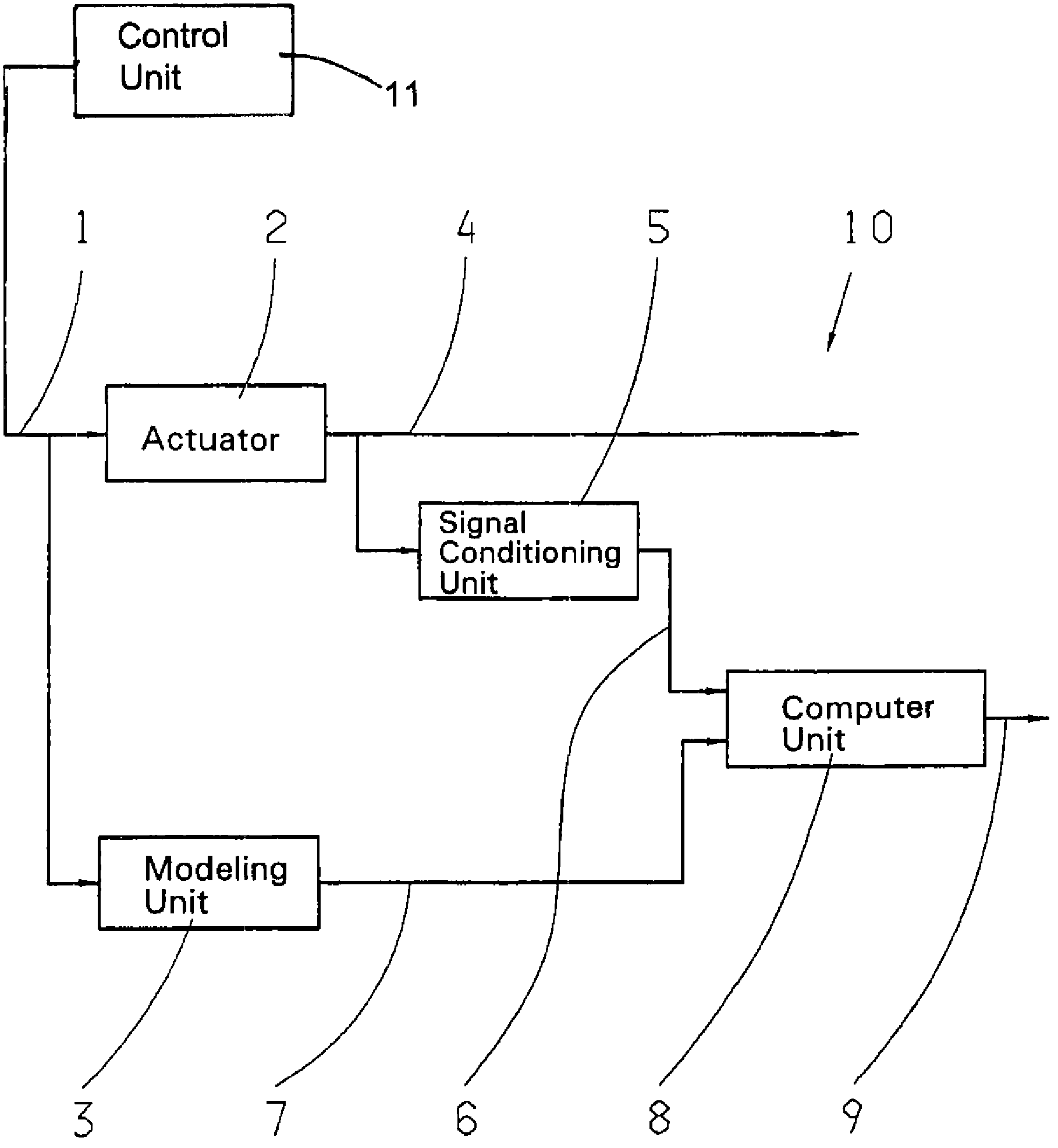

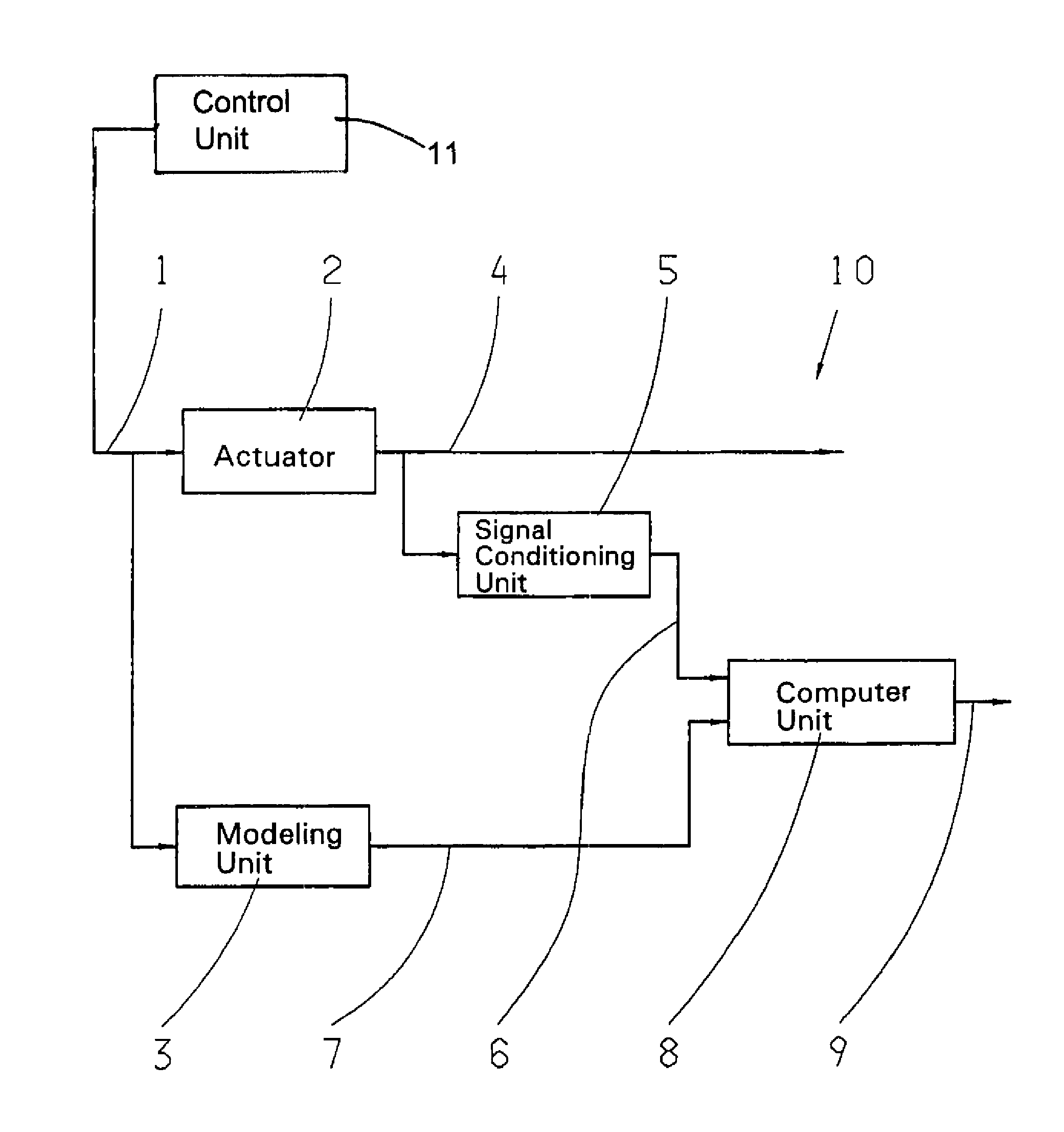

Method for fault detection in an actuator

InactiveUS7827001B2Avoid positioningAvoid separationProgramme controlClutchesSignal conditioningControl engineering

A method for detecting fault in an actuator. By transmitting a control value, which is generated by a control unit, to an input of the actuator a signal for the measured actuator position is produced at the output of the actuator. The signal for the measured actuator position is sent to an input of a signal conditioning unit which determines from it a measure of actuator movement. The control value is also transmitted to an input of a modeling unit, which calculates from it an expected measure of actuator movement. These movements are sent to a computer unit, which produces a corresponding status signal for the functionality of the actuator and for the functionality of the sensor for determining the actuator position.

Owner:ZF FRIEDRICHSHAFEN AG

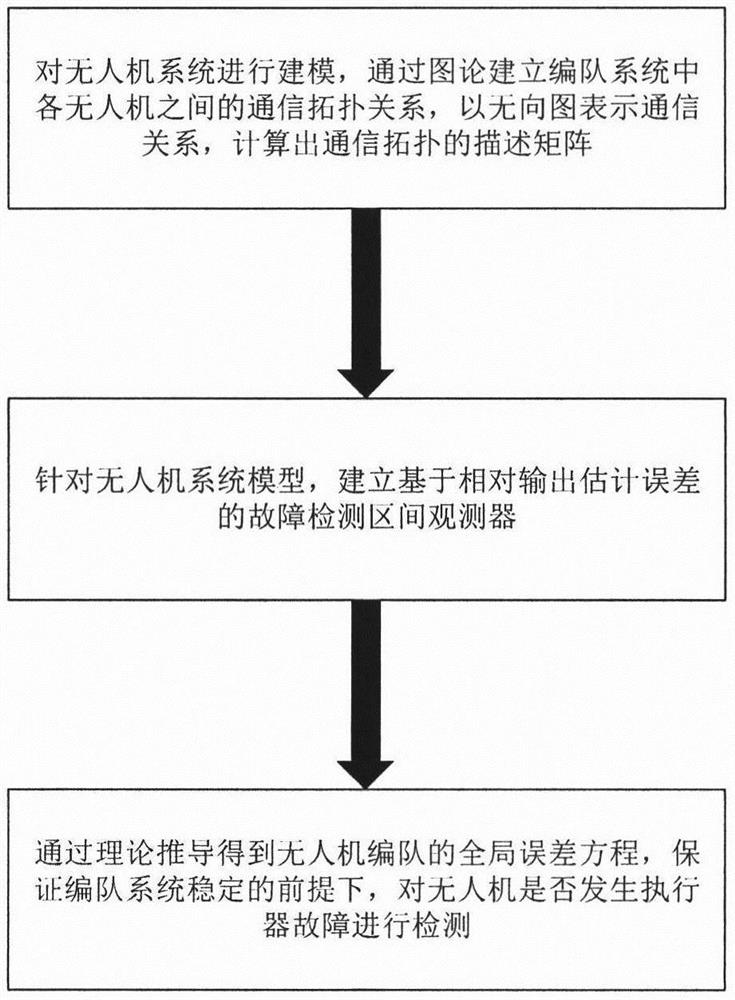

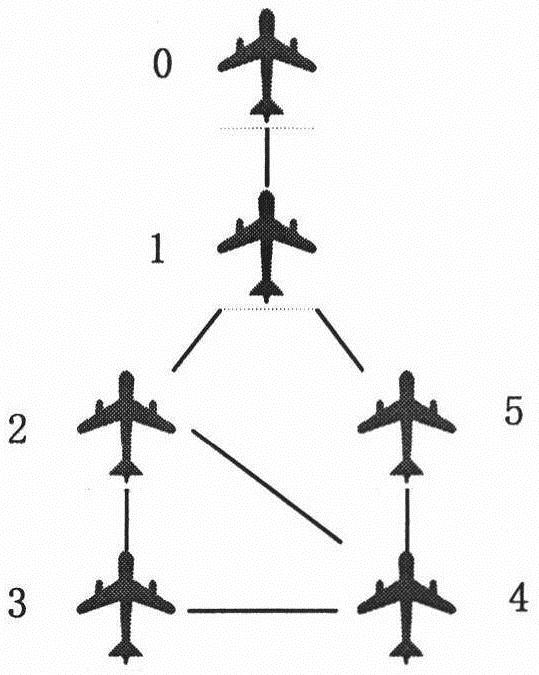

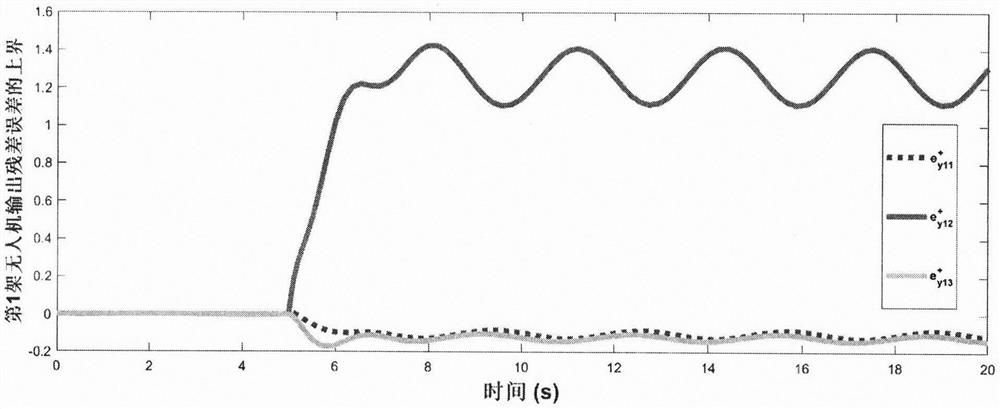

Unmanned aerial vehicle formation system fault detection method based on interval observer

For an unmanned aerial vehicle formation system, the invention provides a fault detection method based on an interval observer, and belongs to the technical field of security and reliability. Firstly,when unmanned aerial vehicle formation is in a fault-free state, the interval observer is established based on known bounded disturbance and relative output errors; the fault of an executor is detected through a residual error obtained by output estimation error; compared with the traditional fault detection, a threshold value generator and a residual evaluation function are not required in the fault detection method based on the interval observer; the method in the invention is mainly used for solving the fault detection problem of an unmanned aerial vehicle formation executor, and has relatively low conservative property and relatively high adaptation; the fault detection requirement of the executor can be well satisfied.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

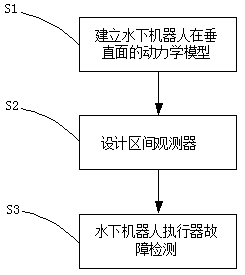

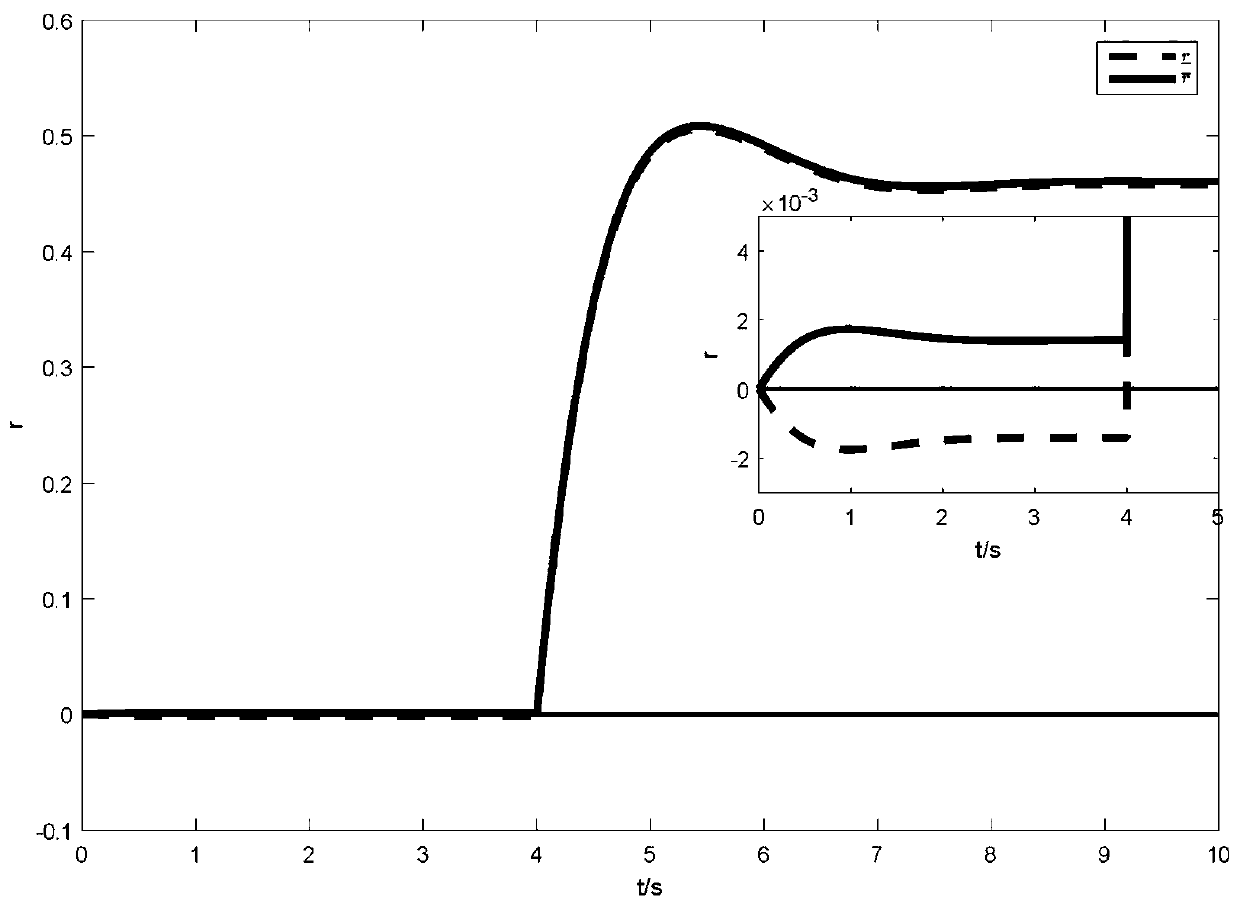

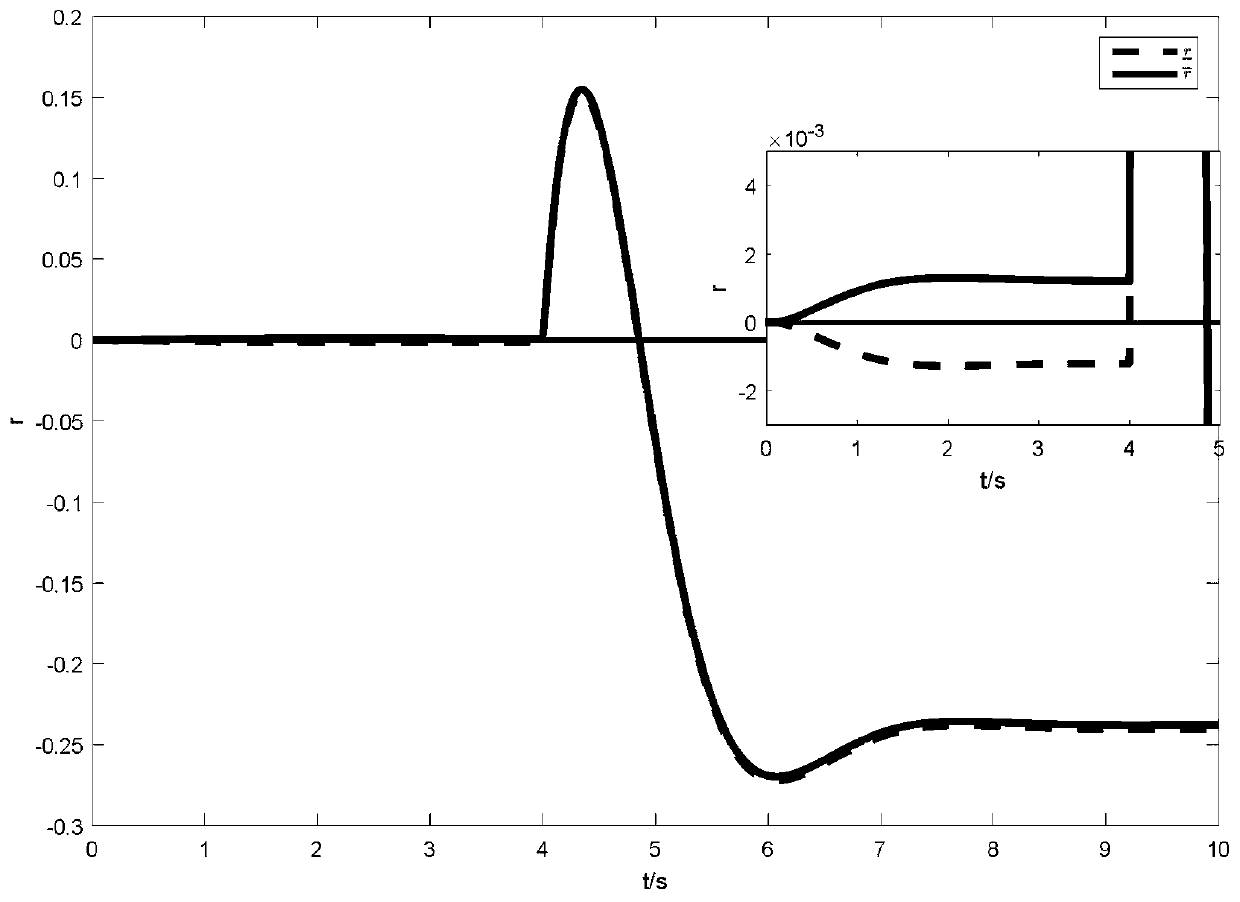

Interval observer based AUV (Autonomous Underwater Vehicle) performer fault detection method

ActiveCN110096048AGuarantee the actual application needsProgramme controlElectric testing/monitoringObserver basedActuator fault detection

The invention provides an interval observer based AUV performer fault detection method. The fault detection module comprises that a dynamic model of an AUV in the vertical plane is established; an interval observer is designed according to the dynamic model; and a fault of a performer is detected according to data of the interval observer. The provided method can be used to find faults timely, andeffectively meet the practical application demands.

Owner:SHANDONG UNIV OF SCI & TECH

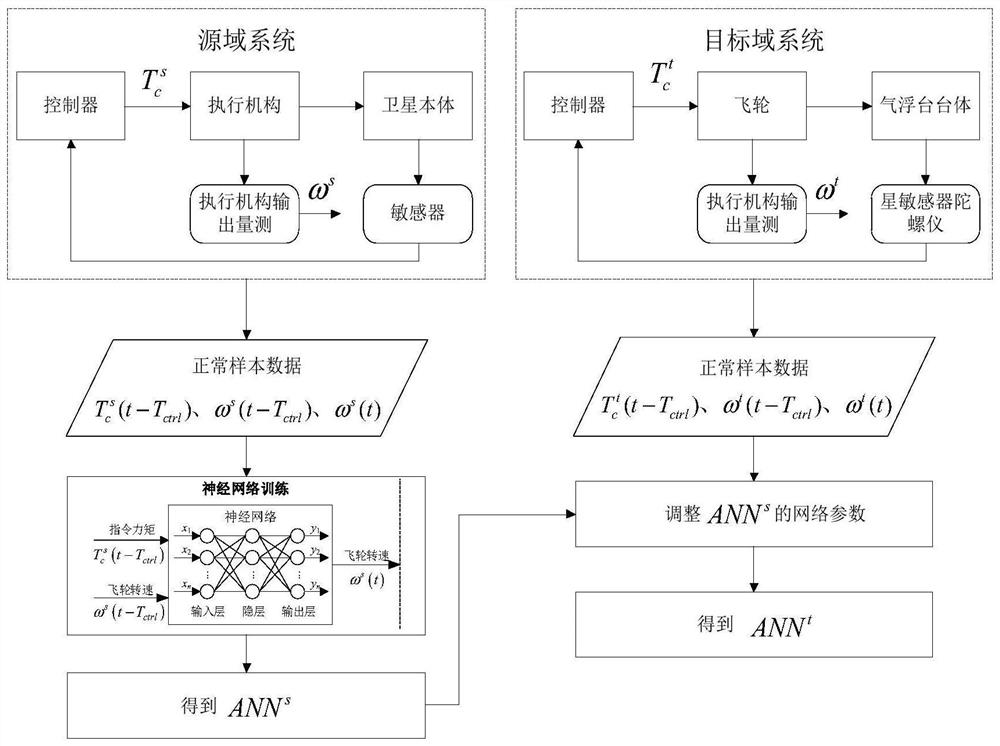

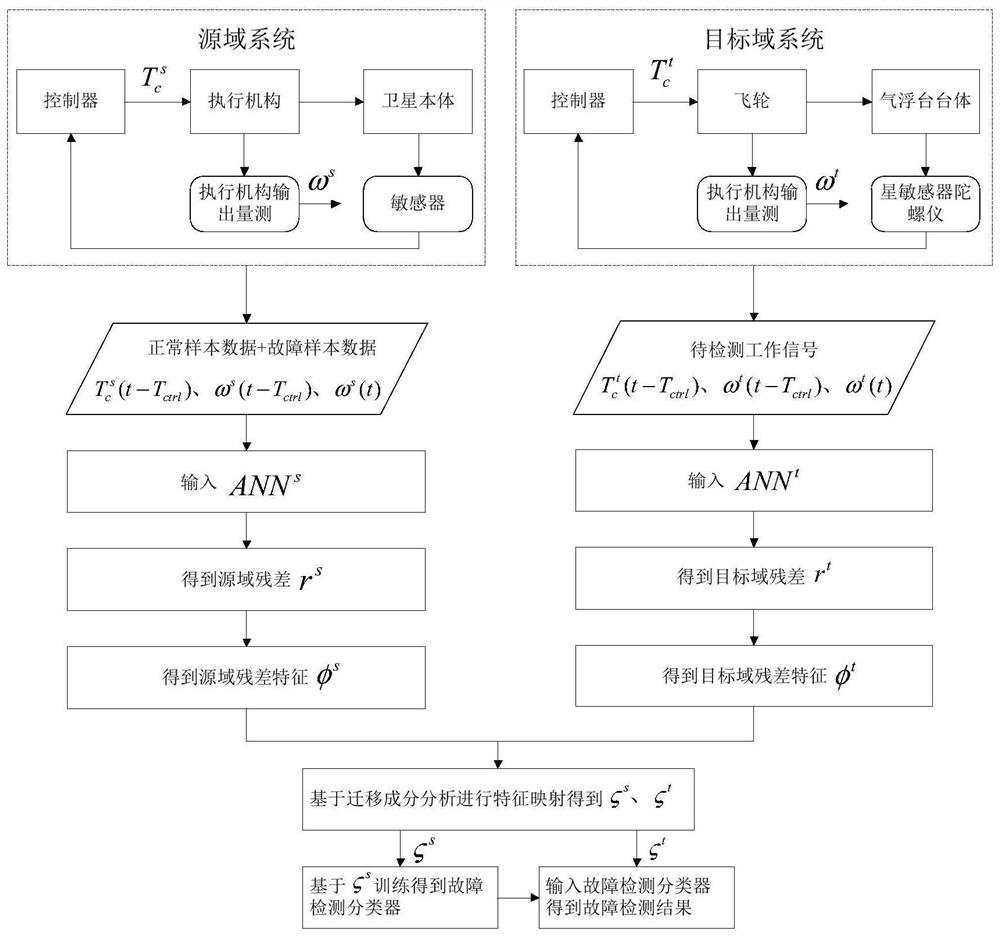

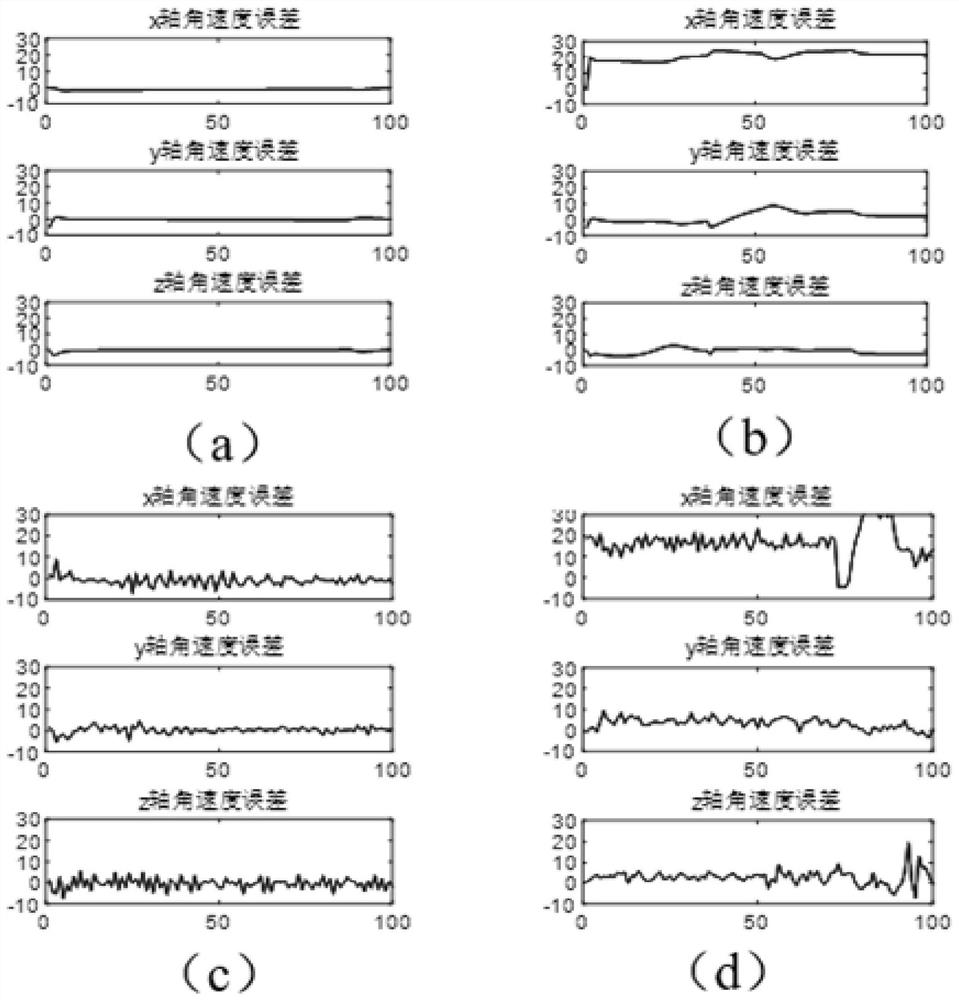

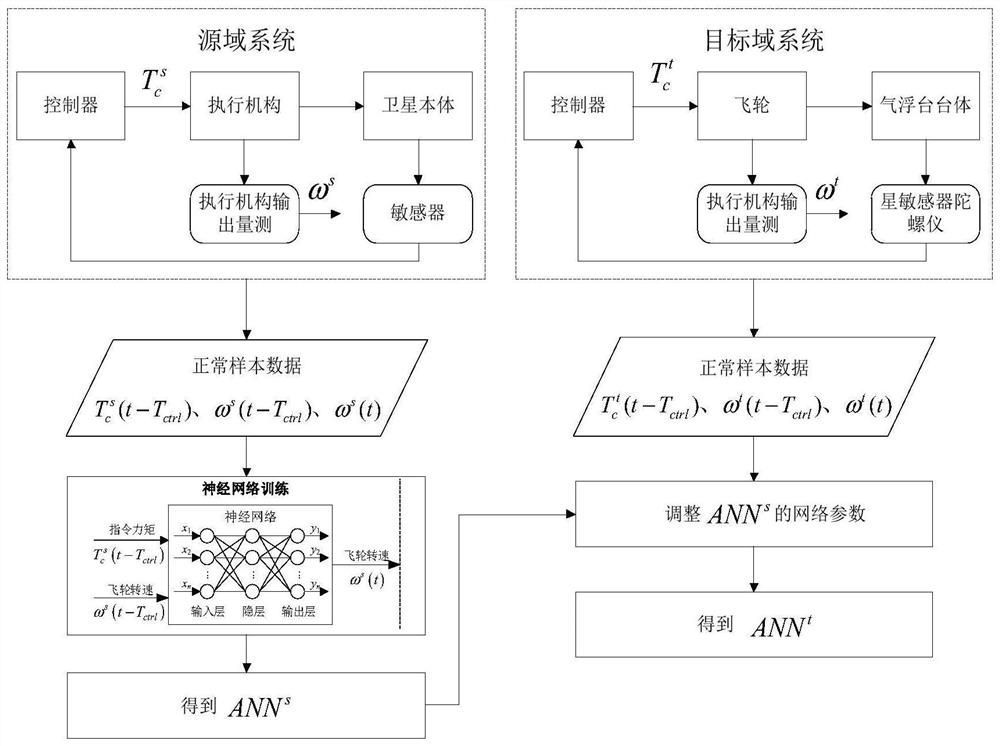

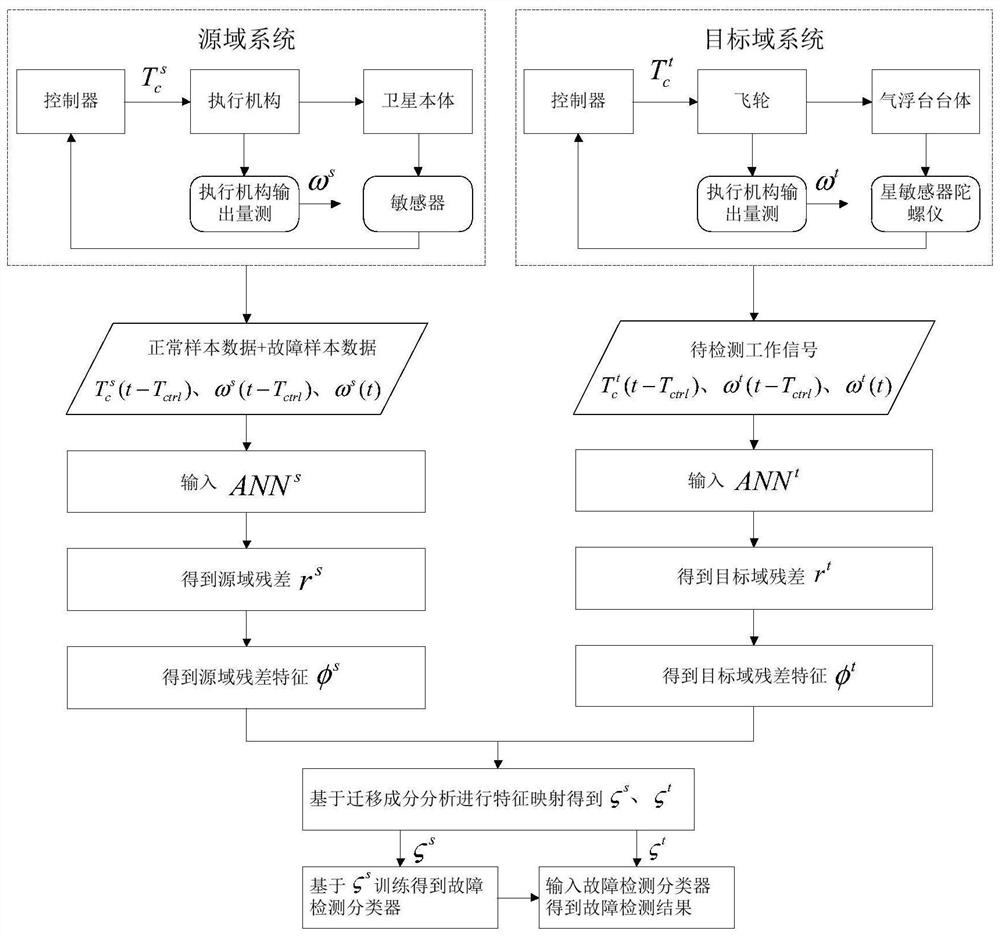

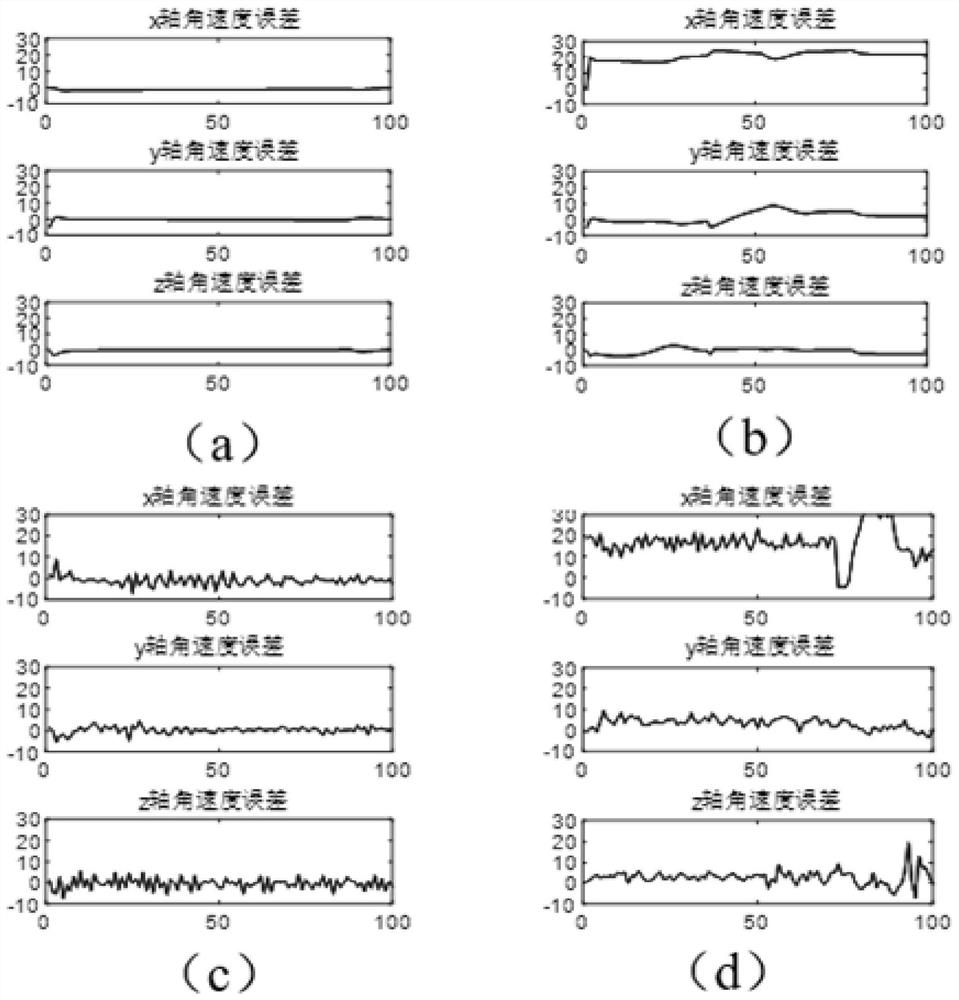

Satellite actuator fault detection method based on migration component analysis

ActiveCN113469082AReduce distribution distanceImprove reliabilitySimulator controlCharacter and pattern recognitionNetwork modelActuator fault detection

The invention discloses a satellite actuator fault detection method based on migration component analysis, and relates to the field of satellite attitude control system fault detection, and the method comprises the steps: obtaining a source domain neural network model based on normal sample data training of a source domain system; utilizing the normal sample data of a target domain system to adjust network parameters to obtain a target domain neural network model, utilizing the network model to obtain source domain and target domain data residual errors, after residual error features are extracted, adopting a migration component analysis method, so the distribution distance of source domain data features and target domain data features is reduced, and a source domain data feature training classifier can be used for diagnosis of actual satellite data samples. According to the invention, the fault detection of a satellite flywheel is realized by using nominal model simulation data and a migration component analysis method aiming at the situation that a satellite has no fault samples, and the reliability and ground monitoring capability of a satellite attitude control system are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

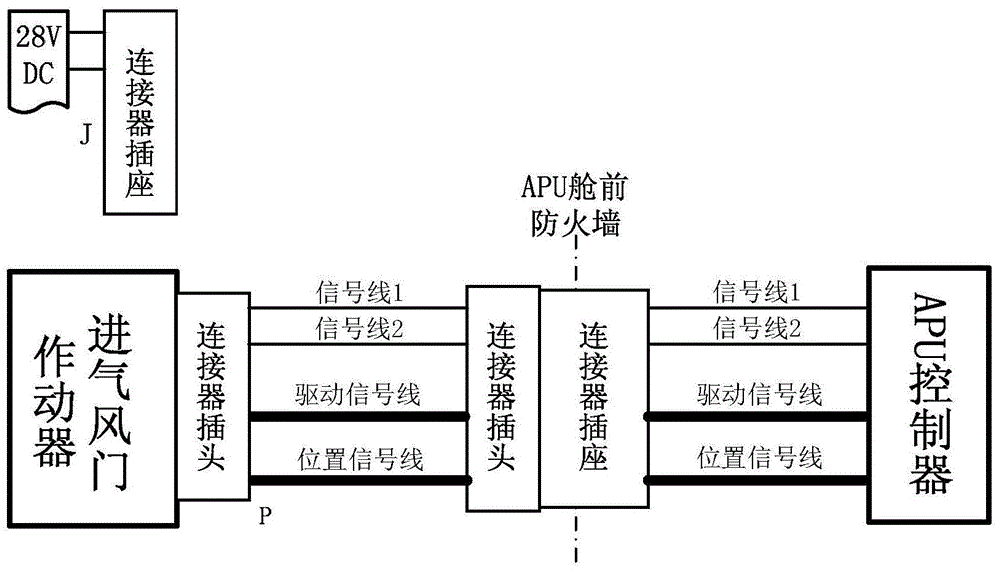

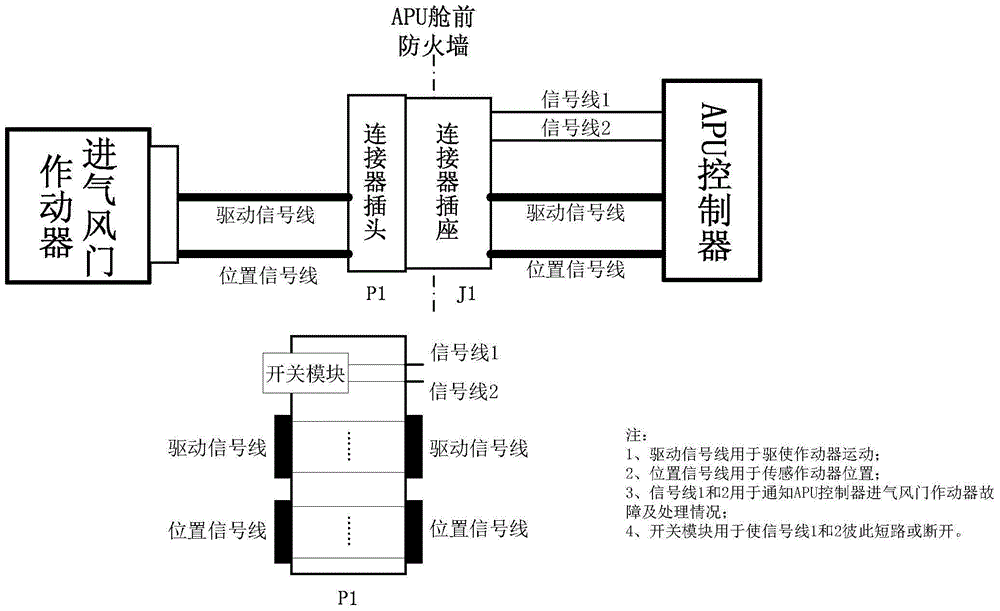

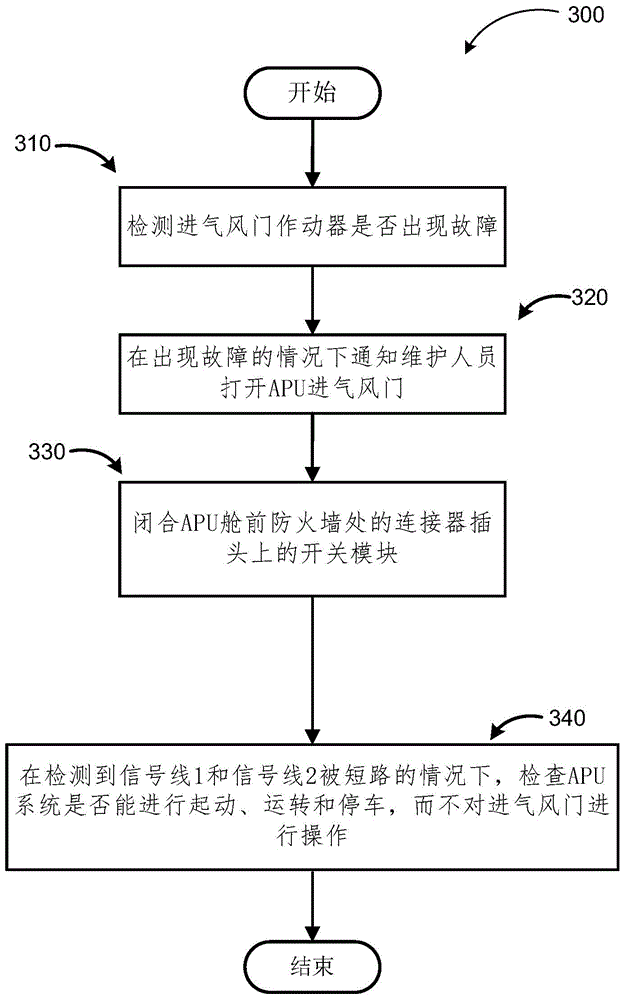

APU air inlet air door actuator fault processing method and device

The invention relates to an APU air inlet air door actuator fault processing method and device. A connector plug used for butting with a connector socket at a firewall in front of an APU compartment is provided. An APU air inlet air door actuator fault detection and processing method is provided.

Owner:COMAC +1

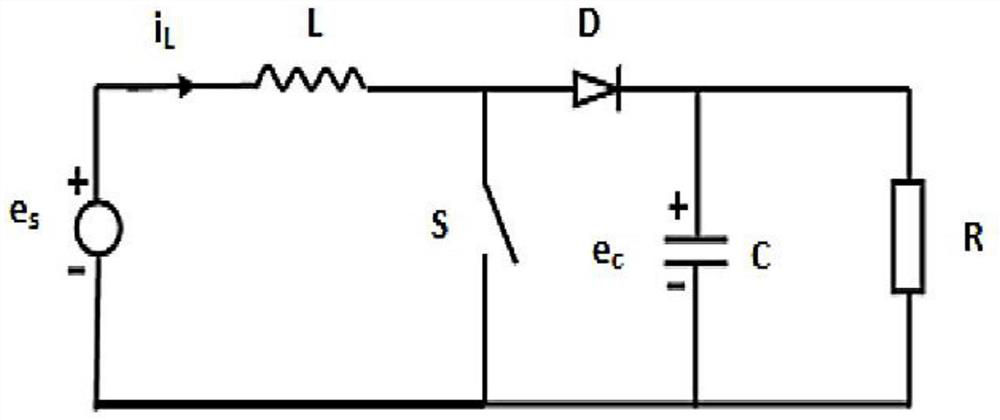

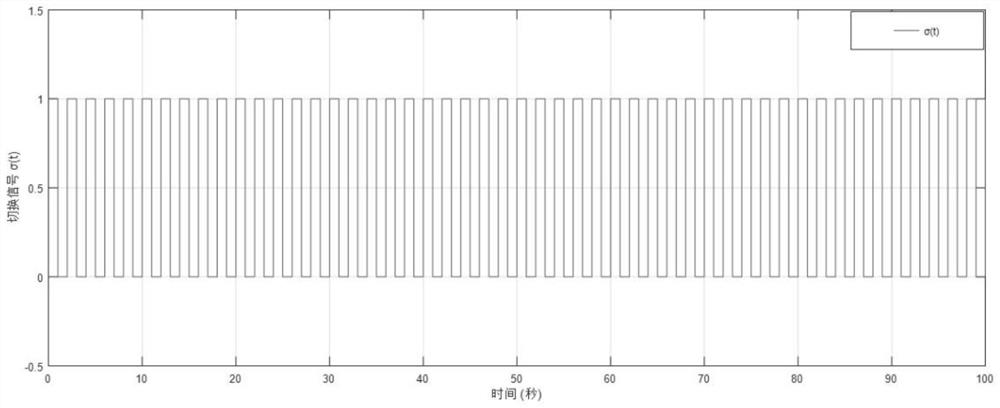

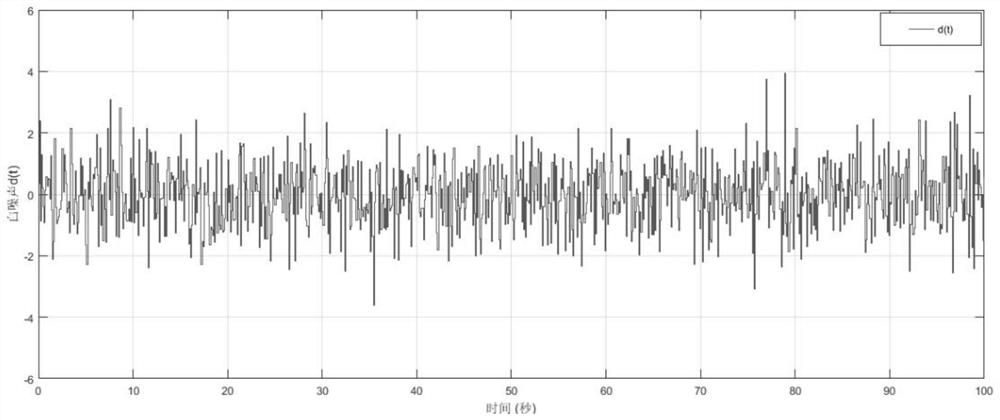

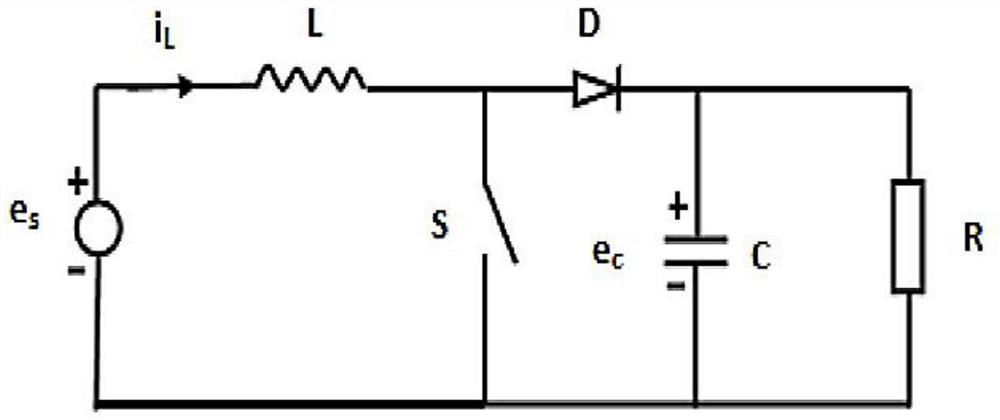

Delta operator-based fault detection method for actuator of boost converter

ActiveCN112733320AContinuous performanceAvoid Numerical InstabilityDesign optimisation/simulationComplex mathematical operationsControl engineeringPerformance index

The invention relates to the technical field of fault diagnosis, and discloses a delta operator-based fault detection method for an actuator of a boost converter, which comprises the steps of establishing a boost converter circuit model, and constructing an augmentation vector; giving a general system model containing external interference and actuator faults; designing an unknown input observer, constructing an augmentation vector, and obtaining a corresponding dynamic estimation error system; for a dynamic estimation error system, giving a sufficient condition meeting an H-infinity performance index, and designing a fault observer parameter; and setting a threshold Jth according to a designed observer, constructing a residual evaluation function, and judging whether the system has a fault or not through decision logic. According to the fault detection method designed in the invention, the error dynamic system satisfies the following conditions: (1) the system is asymptotically stable in the absence of faults and interference; and (2) when the system has faults and interference, a certain H-infinity performance index is satisfied under a zero initial condition, and actuator fault detection of the boost converter circuit system can be completed.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

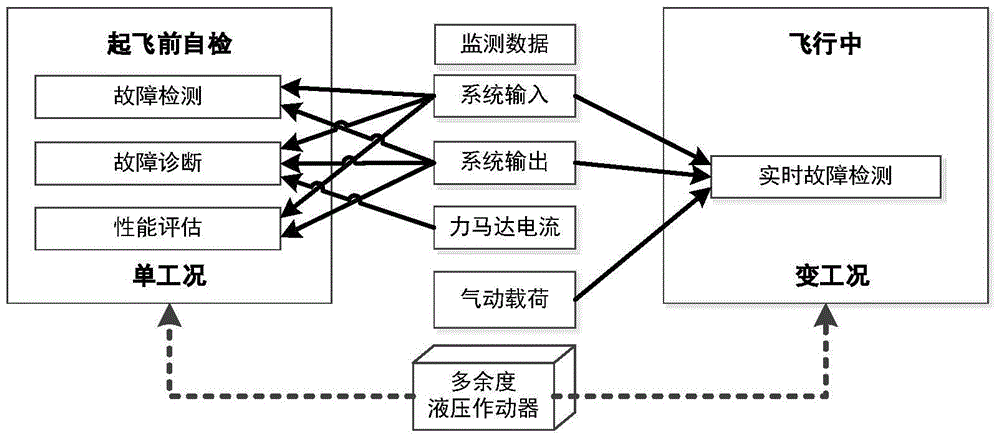

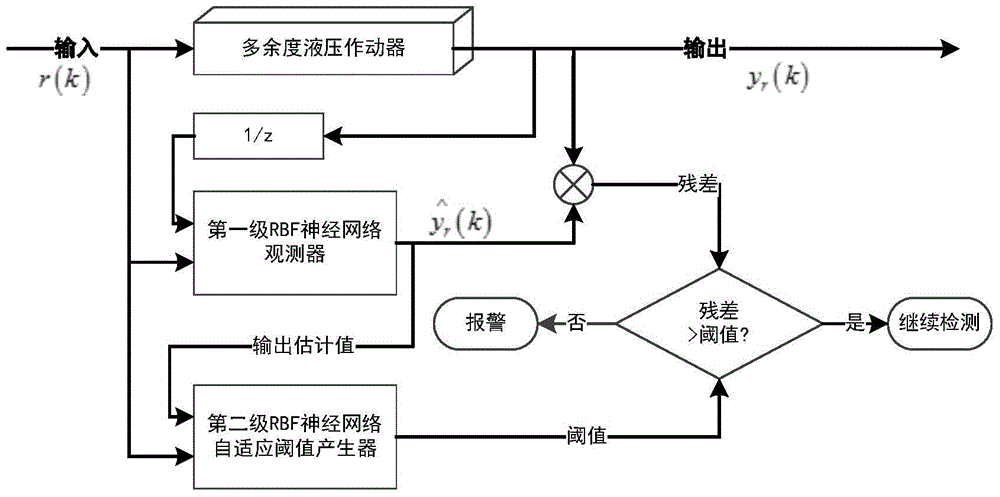

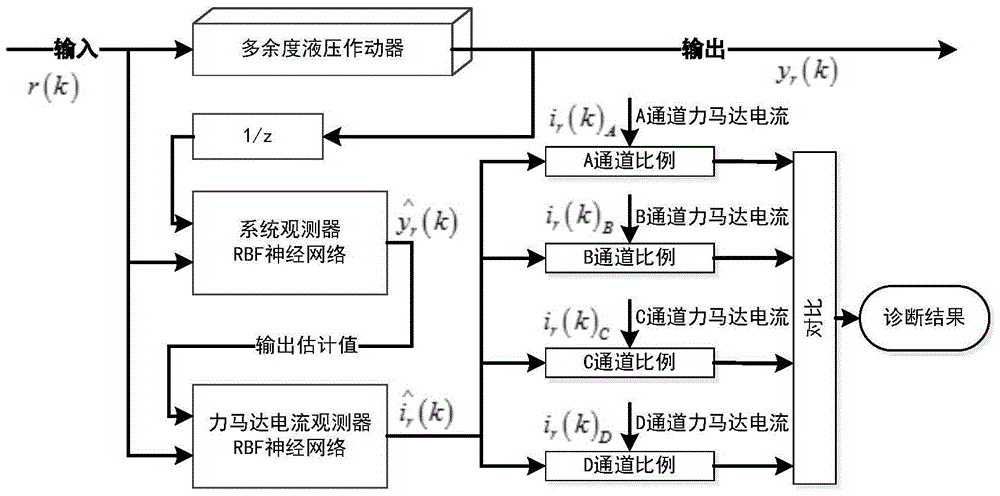

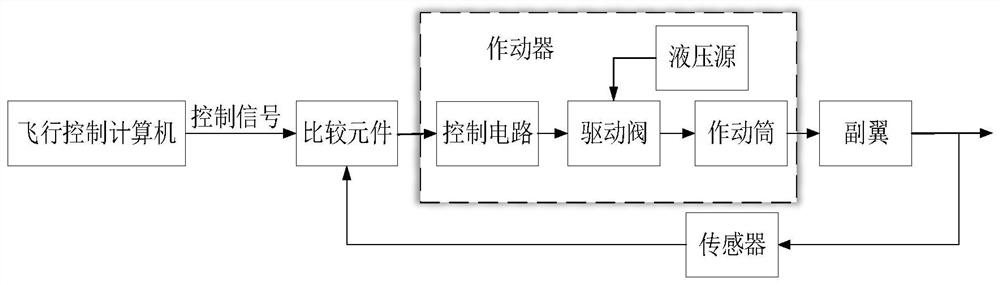

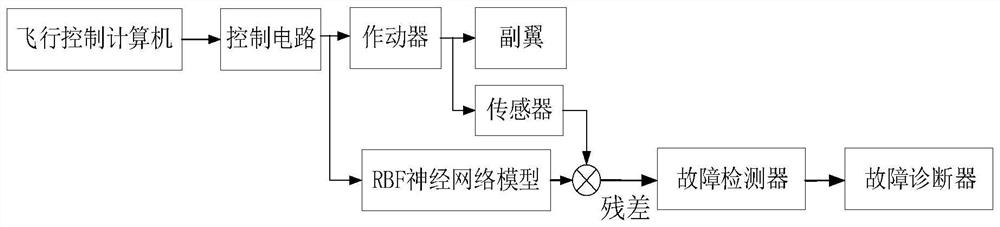

A Fault Detection, Diagnosis and Performance Evaluation Method for Redundancy Aileron Actuator

ActiveCN104390776BImprove accuracyReduce the false alarm rate of detectionMachine part testingFluid-pressure actuator testingTime domainNetwork output

Owner:北京恒兴易康科技有限公司

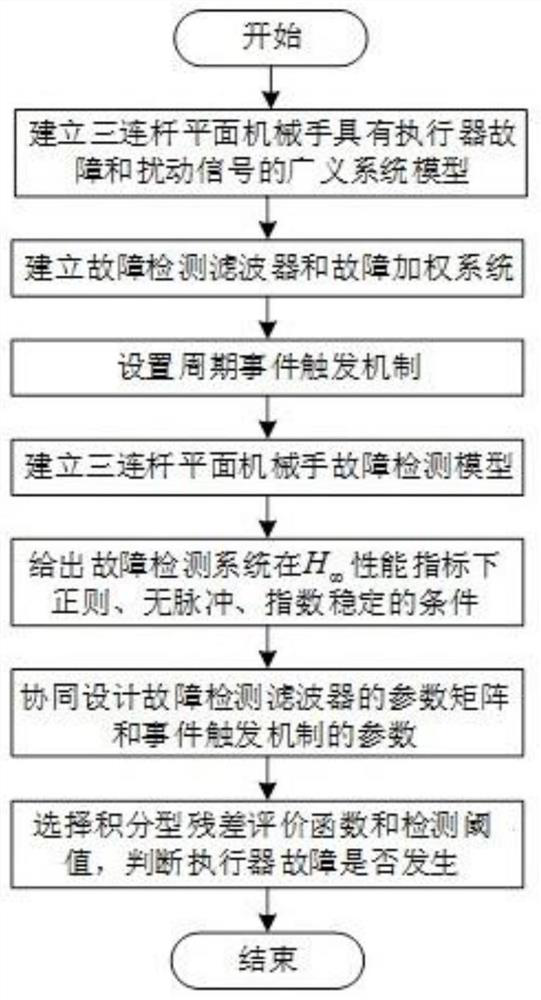

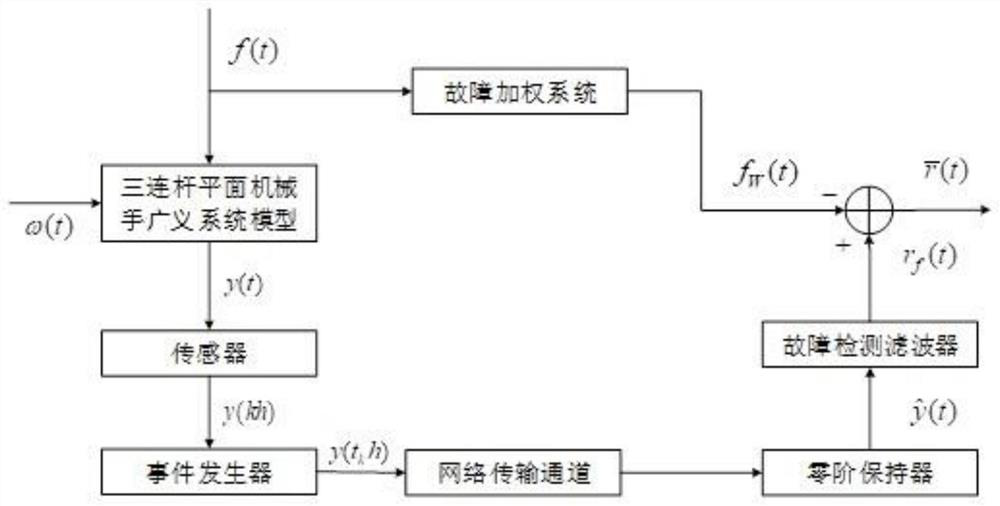

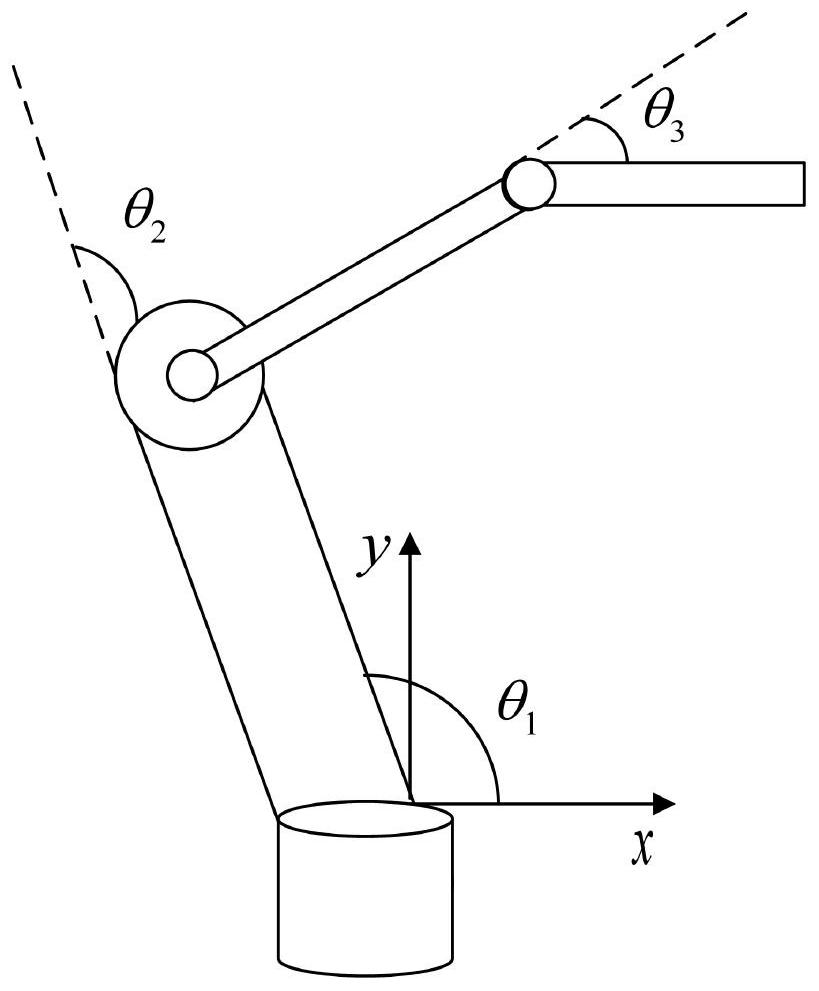

Three-connecting-rod manipulator actuator fault detection method based on event triggering mechanism

PendingCN113997317AMeet the actual application needsLow costManipulatorEvent triggerControl engineering

The invention discloses a three-connecting-rod manipulator actuator fault detection method based on an event triggering mechanism, which comprises the following steps of firstly, selecting a linearized balance point, and establishing a three-connecting-rod plane manipulator generalized system model by considering actuator fault parameters and external disturbance, establishing a three-connecting-rod plane manipulator fault detection system model according to the three-connecting-rod plane manipulator generalized system model, determining regular, pulse-free and exponential stable conditions of the three-connecting-rod plane manipulator fault detection system model under H-infinity performance, and cooperatively designing the three-connecting-rod plane manipulator fault detection system model based on the stable conditions, and designing a residual error evaluation function and a residual error evaluation threshold value based on the residual error, and giving a fault judgment method. According to the method, the fault of an actuator can be detected in time, safe and reliable operation of a manipulator is guaranteed, limited network bandwidth can be saved, and the method has extremely high practical application value.

Owner:NANJING UNIV OF POSTS & TELECOMM

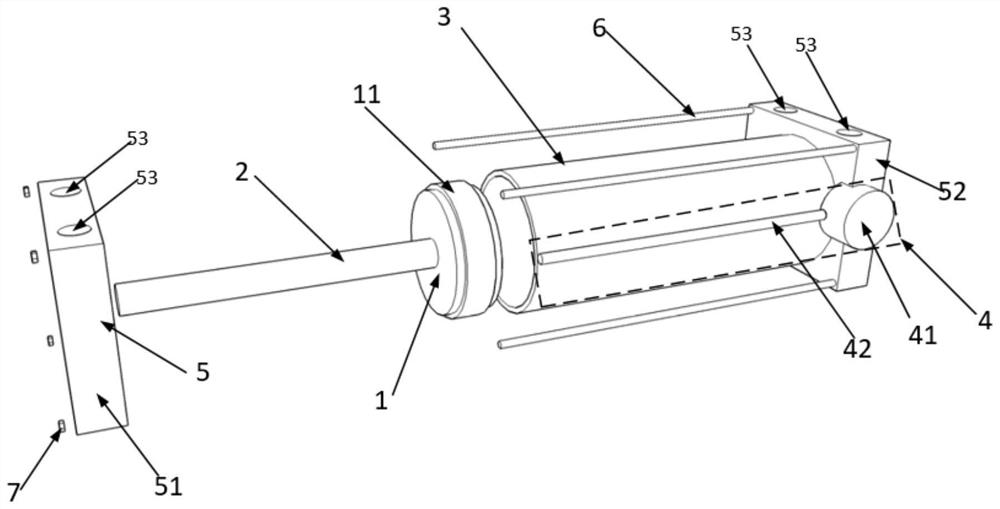

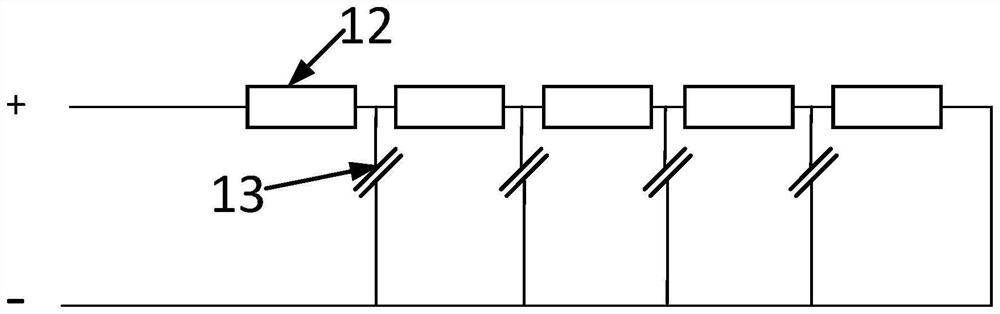

Pneumatic actuator fault detection device

PendingCN114484052AShorten the timeImprove maintenance efficiencyOperating means/releasing devices for valvesFluid-pressure actuatorsControl engineeringActuator fault detection

The invention discloses a pneumatic actuator fault detection device which is used for detecting the actual fault position of a gate, reducing the troubleshooting time for detecting the fault position and improving the troubleshooting efficiency. The device comprises a piston, a piston rod, a cover plate, a cylinder barrel and a sensor, the cover plates are fixed to the two ends of the cylinder barrel and used for being matched with the cylinder barrel to form a sealed space. The piston is arranged in the cylinder barrel, and the cylinder barrel is used for providing a movement track of the piston; one end of the piston rod is located in the cylinder barrel and connected with the piston, the other end of the piston rod penetrates through the cover plate and is connected with a gate, and the piston is used for driving the gate to move through the piston rod; the sensor is fixed to the outer side of the cylinder barrel and used for sensing the position of the piston.

Owner:江苏南热发电有限责任公司

A Fault Detection and Diagnosis Method for Aircraft Actuators Based on Deep Random Forest Algorithm

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A fault detection method for satellite actuators based on migration component analysis

ActiveCN113469082BReduce distribution distanceImprove reliabilitySimulator controlCharacter and pattern recognitionSatellite dataEngineering

The invention discloses a satellite actuator fault detection method based on migration component analysis, and relates to the field of satellite attitude control system fault detection. The method obtains a source domain neural network model based on normal sample data training of the source domain system, and utilizes the target domain system The normal sample data adjusts the network parameters to obtain the neural network model of the target domain, and uses the network model to obtain the residual data of the source domain and the target domain. The distribution distance enables the classifier trained by the source domain data features to be used for the diagnosis of actual satellite data samples. This method is aimed at the situation of satellites without fault samples, using the nominal model simulation data and the migration component analysis method to realize the fault detection of satellite flywheels , improving the reliability of the satellite attitude control system and ground monitoring capabilities.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

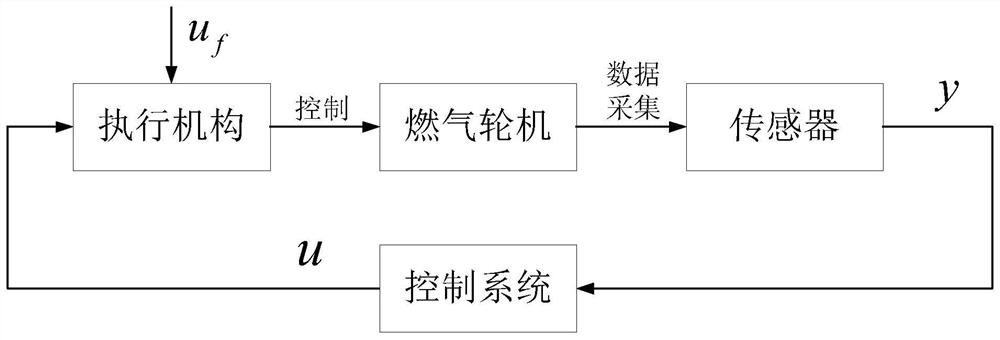

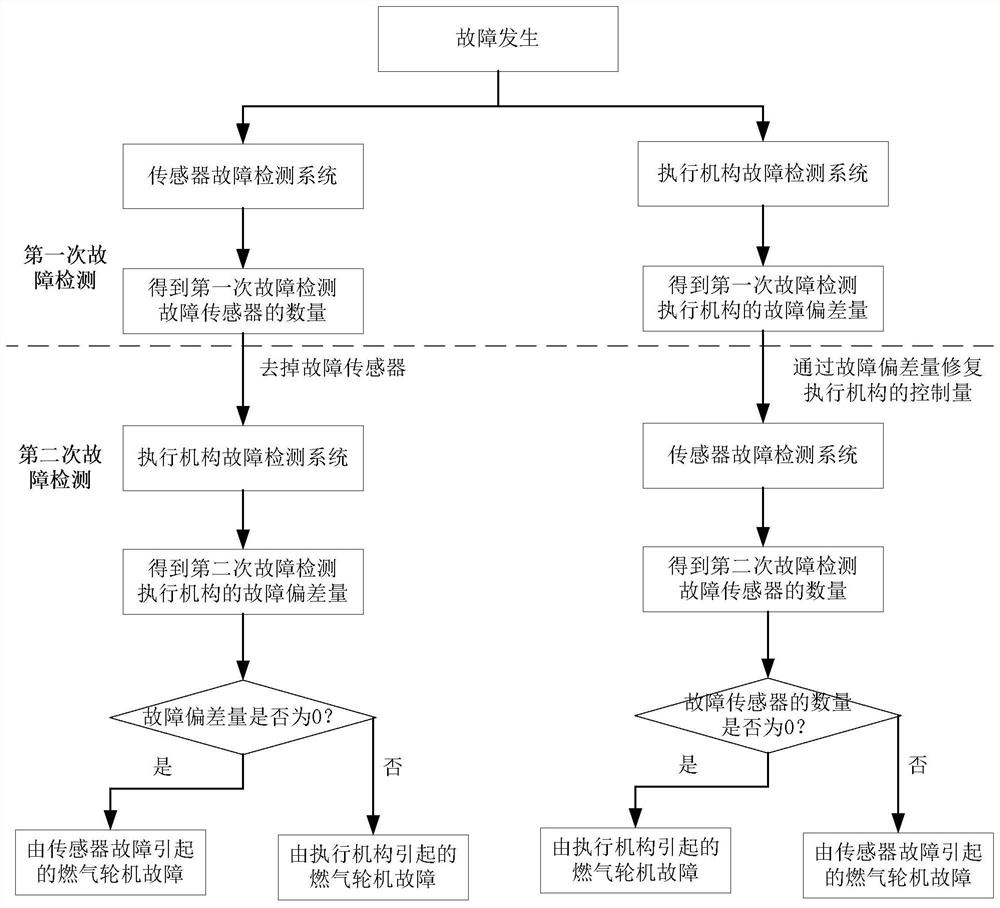

Fault detection method for gas turbine sensors and actuators based on cross-validation

ActiveCN113447273BGuaranteed availabilityGuaranteed uptimeInternal-combustion engine testingComplex mathematical operationsControl systemControl engineering

A method for detecting faults of gas turbine sensors and actuators based on cross-validation belongs to the technical field of gas turbines. In order to solve the problem of how to realize sensitive detection and isolation of actuator and sensor faults in the process of state monitoring of gas turbines. The method of the present invention includes the following steps: S1. After the fault occurs, perform the first fault detection through the sensor fault detection system and the actuator fault detection system to determine the number of faulty sensors and the fault deviation of the actuator; S2, remove all faults The sensor sends the actual measurement value of the sensor that has not failed to the fault detection system of the actuator; at the same time, the control value output by the control system to the actuator is repaired through the fault deviation of the actuator obtained in step S1, and its It is sent to the sensor fault detection system; the second fault detection is carried out to realize the determination of the cause of the gas turbine failure. Mainly used for fault detection.

Owner:HARBIN INST OF TECH +2

Actuator fault detection device, controlling device and control method

An actuator fault detection device that detects a fault of an actuator driven according to a manipulation variable MV output from a controlling device, including: a position acquiring portion that acquires a value of a motor position MP from a detector that detects a position of an actuator corresponding to a manipulation variable MV; a follow-up difference calculating portion that calculates a follow-up difference DM=MV−MP; and an allowable range determining portion that determines whether or not high speed operation or low speed operation of the actuator departs from an allowable range based on a manipulation variable change rate ΔMV, an actuator position change rate ΔMP, and the follow-up difference DM.

Owner:YAMATAKE HONEYWELL CO LTD

A Fault Detection Method for UAV Formation System Based on Interval Observer

The invention proposes a fault detection method for an interval observer aiming at an unmanned aerial vehicle formation system. It belongs to the technical field of safety and reliability. First, an interval observer is established based on known bounded disturbances and relative output errors when the UAV formation is in a fault-free state. The residual obtained by outputting the estimated error is used to detect actuator faults. The difference from traditional fault detection lies in that this fault detection method based on interval observer does not need threshold generator and residual evaluation function. The invention mainly solves the fault detection problem of the unmanned aerial vehicle formation actuator, has low conservatism and strong adaptability, and can well meet the requirements of actuator fault detection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A boost converter actuator fault detection method based on delta operator

ActiveCN112733320BContinuous performanceAvoid Numerical InstabilityDesign optimisation/simulationComplex mathematical operationsHemt circuitsControl engineering

The invention relates to the technical field of fault diagnosis, and discloses a fault detection method for a boost converter actuator based on a delta operator, which establishes a boost converter circuit model, constructs an augmented vector; The general system model of ; design the unknown input observer, construct the augmented vector, and get the corresponding dynamic estimation error system; for the dynamic estimation error system, give the satisfying H ∞ The sufficient condition of the performance index, design the parameters of the fault observer; according to the designed observer, set the threshold J th , construct the residual evaluation function, and judge whether the system is faulty or not through decision-making logic. The fault detection method designed in the present invention makes the error dynamic system satisfy: (1) when there is no fault and no disturbance, the system is asymptotically stable; (2) when the system has faults and disturbances, under zero initial conditions, a certain h ∞ The performance index can complete the actuator fault detection of the boost converter circuit system.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

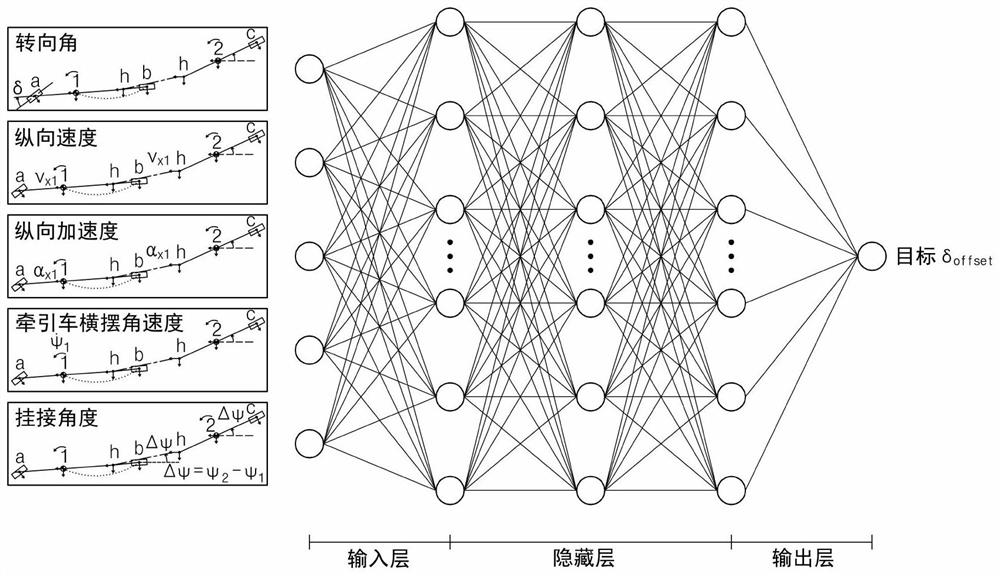

Vehicle actuator fault detection apparatus and detection method

PendingCN114115169AThe advantage remains the sameProgramme controlMachine gearing/transmission testingBehavioral dataActuator fault detection

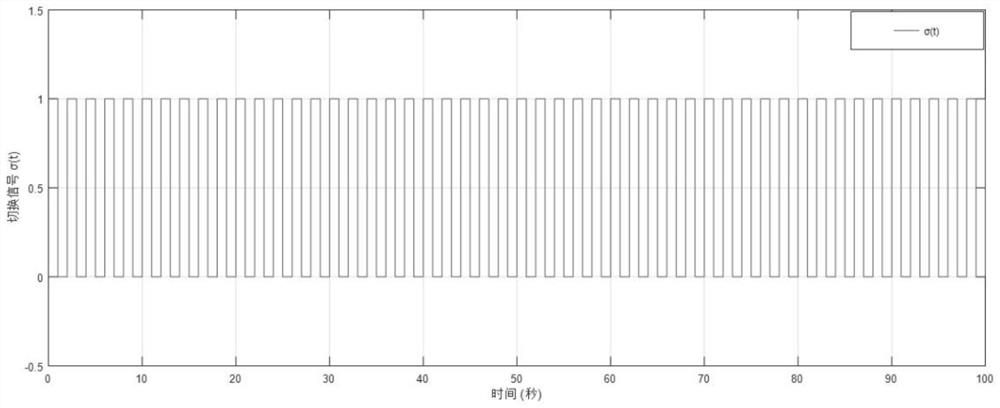

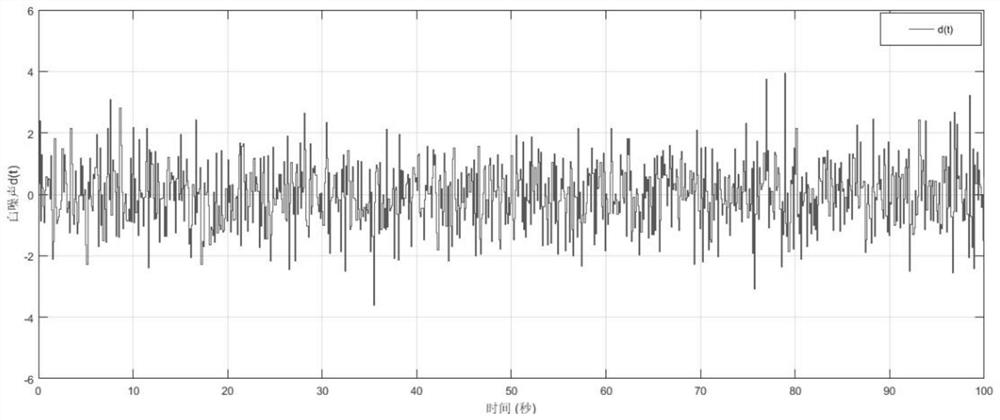

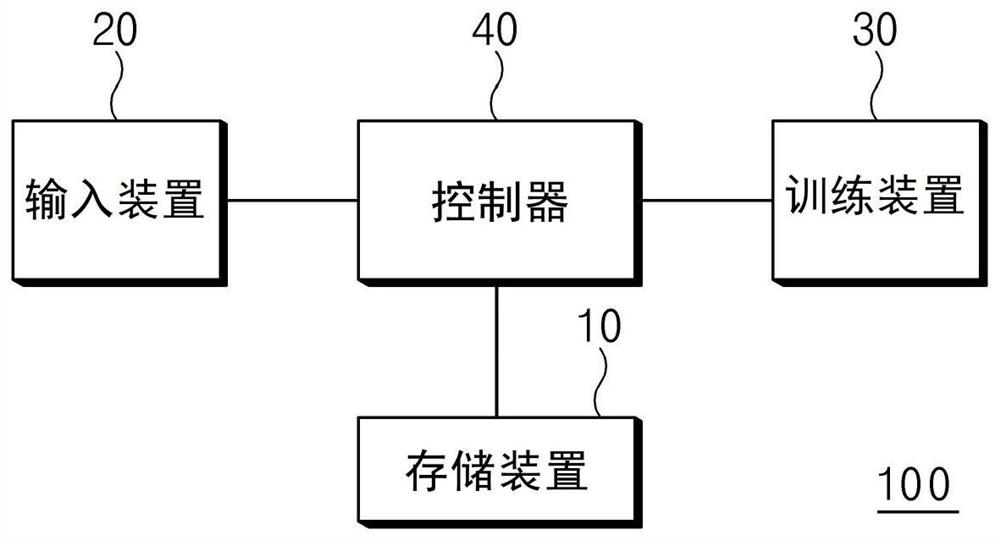

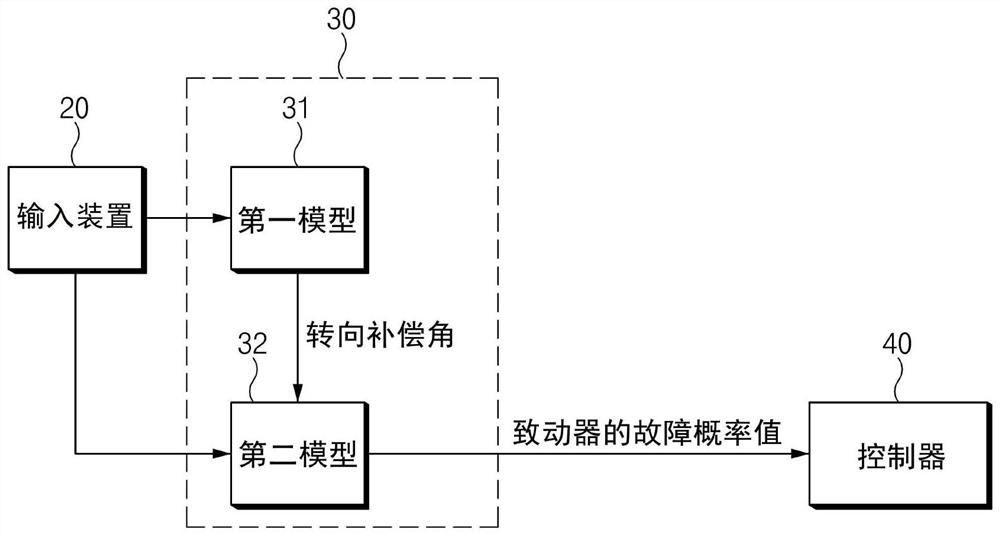

The present disclosure relates to a vehicle actuator failure detection apparatus and detection method, the vehicle actuator failure detection apparatus comprising: a training device that trains a model using training data including behavior data of a vehicle and a steering compensation angle; and a controller detecting a failure of an actuator in the vehicle based on the model.

Owner:HYUNDAI MOTOR CO LTD +1

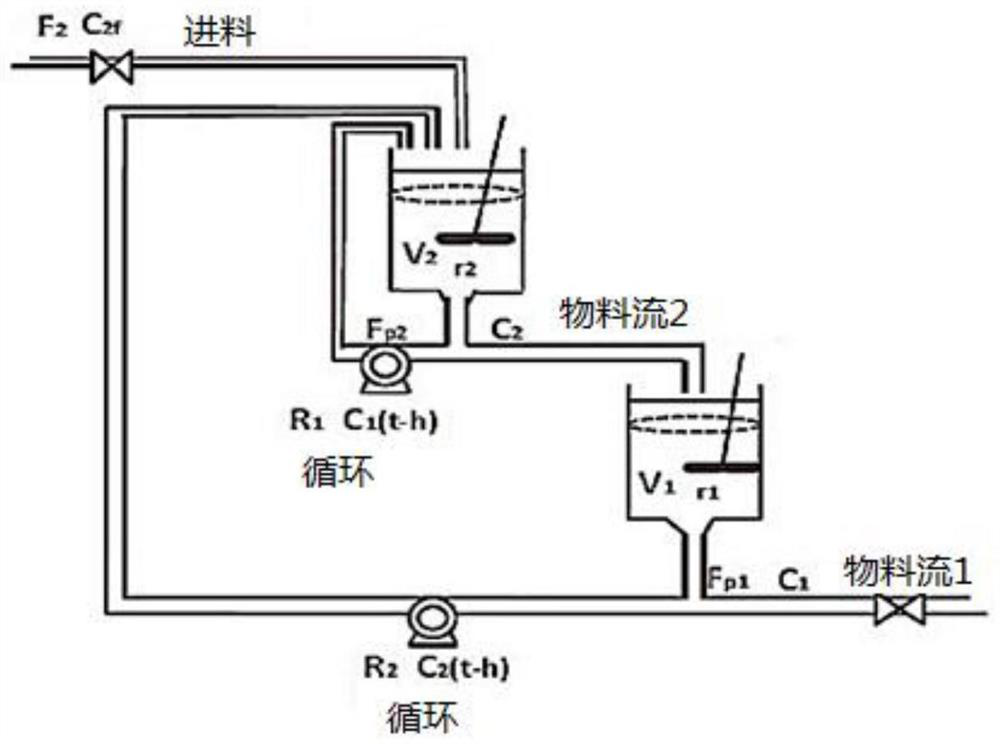

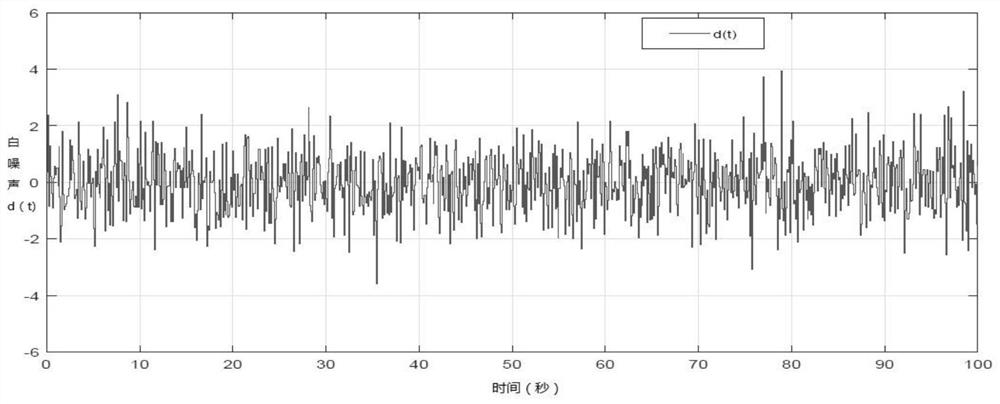

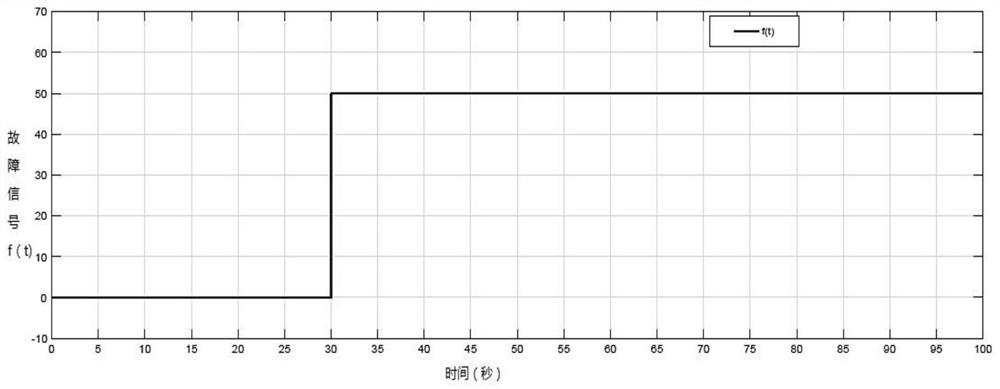

Secondary chemical reactor actuator fault detection method based on function observer

ActiveCN113189973AReduce online computing timeMeet online fault detectionProgramme controlElectric testing/monitoringChemical reactionChemical reactor

The invention discloses a secondary chemical reactor executing mechanism fault detection method based on a function observer. The method comprises the following steps of: firstly, constructing a mathematical model of a system according to the principle of a secondary chemical reactor, and converting the mathematical model into a state equation in a standard form; according to a state equation of the secondary chemical reactor, giving a general form when the secondary chemical reactor has external disturbance and an execution mechanism has a fault; designing a function observer, and giving an error dynamic variance, and a decision logic for judging whether the system breaks down or not; giving a sufficient condition for asymptotic stability of an error dynamic system, and obtaining a fault detection observer parameter according to the sufficient condition; and performing secondary chemical reactor actuator fault detection by using a fault detection observer according to the decision logic. The fault detection method designed in the invention has robustness to unknown input and relatively high sensitivity to faults, does not need to calculate a threshold value, reduces online calculation time, and can complete fault detection of the execution mechanism of the secondary chemical reactor system.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com