Multi-model-based high speed train suspension system multi-actuator fault detection and isolation method

A technology for suspension systems and high-speed trains, which is applied in the field of fault diagnosis of high-speed train suspension systems, and can solve problems such as failure detection and isolation of actuators in high-speed train suspension systems that cannot be effectively solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further explained below in conjunction with the accompanying drawings.

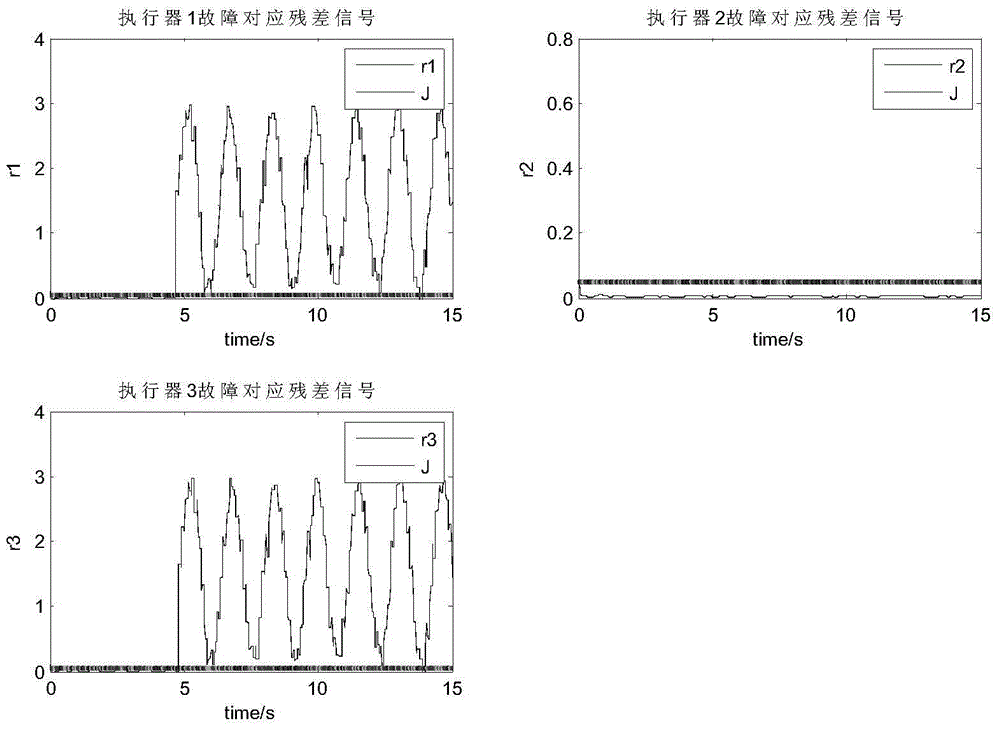

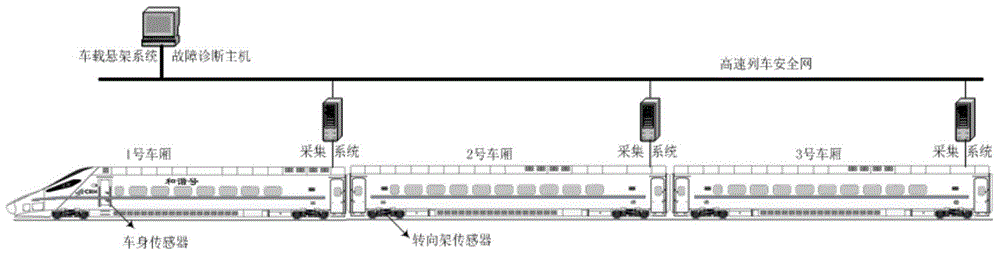

[0068] figure 1 For the overall indication, according to figure 1 , the present invention proposes a multi-model based high-speed train suspension system multi-actuator fault detection and isolation method, the specific steps are as follows:

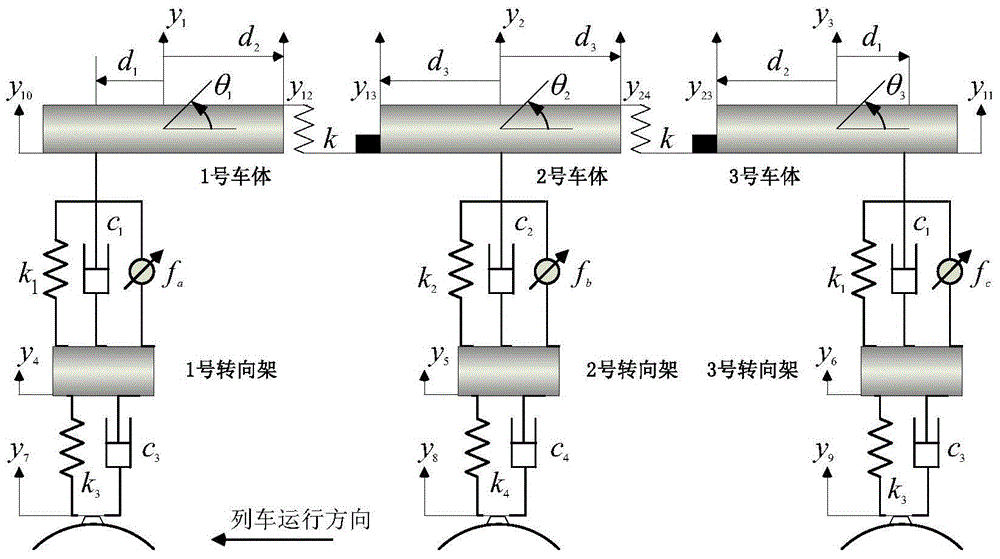

[0069] Step 1: According to figure 2 The vertical structure diagram of the suspension system is shown, and its state space expression is established.

[0070] make x 1 = y · 1 θ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com