Anti-explosion wall end shear seam composite profile

A composite profile and blast-resistant wall technology, applied in the direction of walls, building types, building thermal insulation materials, etc., can solve problems such as structural damage of concrete columns, and achieve the effects of soft and deformable material, prevention of running, and good fire resistance and flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

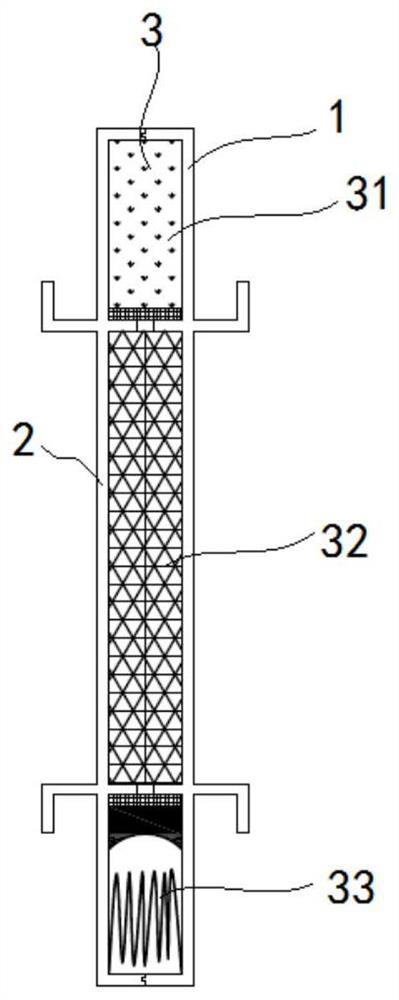

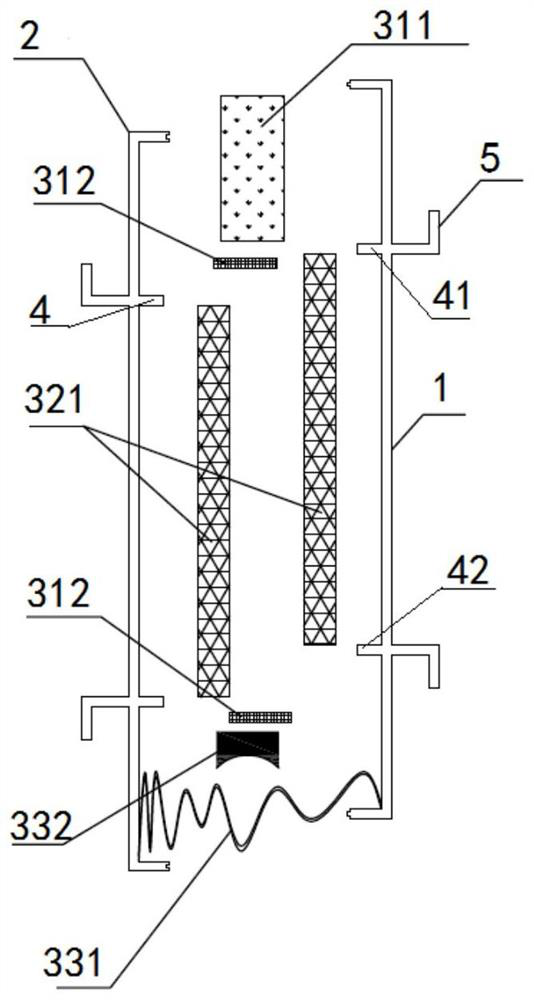

[0052] A shear joint composite profile at the end of an anti-blast wall includes a first shell 1 and a second shell 2 of the same structure, and the first shell 1 and the second shell 2 enclose a multifunctional chamber 3 .

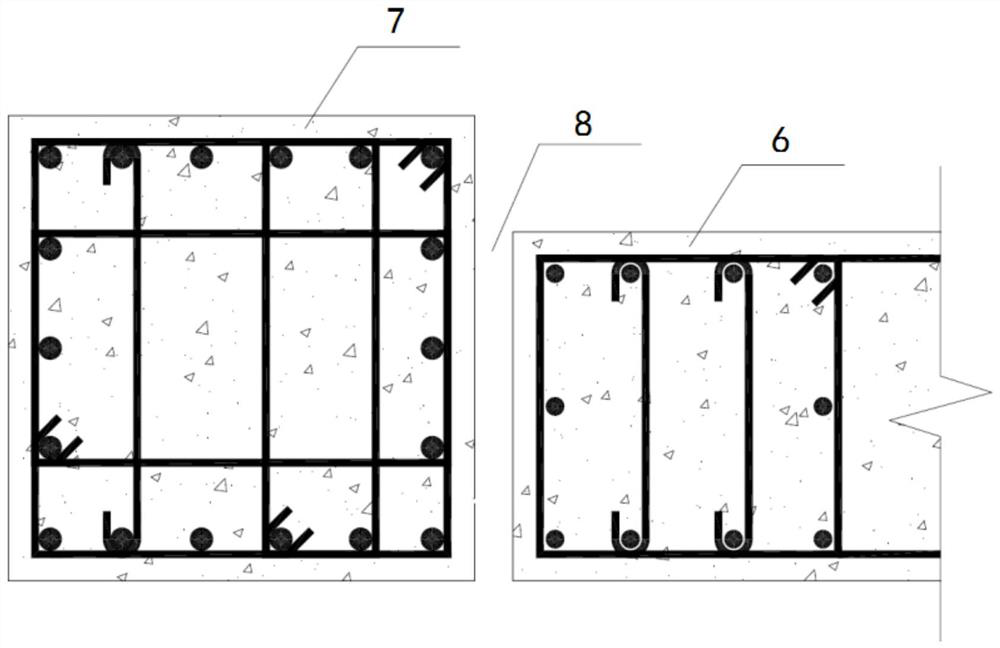

[0053] Specifically, such as figure 1 Among them, the side of the first housing 1 opposite to the blast-resistant wall 6 is provided with a pre-embedded fixing key 5 , and the side of the second housing 2 opposite to the structural column 7 is provided with a pre-embedded fixing key 5 . During application, the steel bars of the first shell 1 and the blast-resistant wall 6 are bound and fixed, and the steel bars of the second shell 2 and the structural column 7 are bound and fixed. Slit 8, such as Figure 3-4 shown in .

[0054] Such as figure 1 Among them, the first shell 1 and the second shell 2 enclose a multi-functional chamber 3, and the opposite sides of the first shell 1 and the second shell 2 are provided with transverse partitions 4, from close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com