Discharging method for shipyard steel plate storage yard

A technology for steel plate yard and shipyard, which is applied in the field of discharge of steel plate yard in shipyard, can solve the problems of long residence time, time-consuming and labor-intensive, and many times of hoisting and flipping the designated steel plate, so as to reduce the risk of risk reduction. , the effect of balancing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

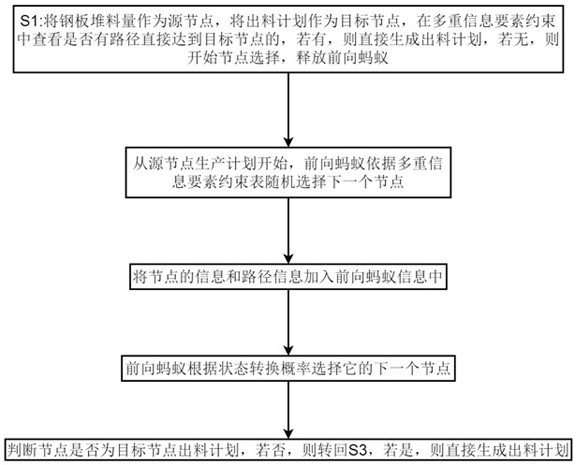

[0032] Please refer to the attached figure 1 , the technical problem to be solved in this embodiment is that the domestic shipyards have not carried out scientific planning for the steel plate storage yard, and it is easy to cause some steel plates to stay in the steel plate warehouse for too long in the links of steel plate discharge and stacking, and the specified required steel plates are overturned. The number of plates is too many to consume time and labor. The discharge of steel plate yards in shipyards has the characteristics of complex constraints, dynamic randomness, and multi-directionality.

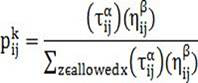

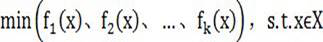

[0033] Complicated and restrictive: As an important link in the management of steel plate yards, the discharge plan plays a role in connecting the execution of the large-scale production plan and the pretreatment of online materials. The discharge plan algorithm is to obtain the theoretical optimal solution of the performance index under the multiple constraints of equality and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com