Nicotine composition, method for making and aerosol generating articles comprising such

A technology of nicotine and composition, which is applied in the field of nicotine composition, and can solve problems such as difficult control of extraction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0211] A tobacco starting material prepared from smoked and flue-cured tobacco materials. The tobacco material was cut to form tobacco chips having dimensions of 2.5 mm x 2.5 mm, and the tobacco chips were loaded into the extraction chamber without compression. The tobacco starting material was heated in the extraction chamber to a temperature of 130 degrees Celsius for a period of 3 hours. During heating, nitrogen flow was passed through the extraction chamber at a flow rate of about 40 liters / minute.

[0212] Volatile compounds released from the tobacco starting material during the heating step were collected by absorption into a liquid solvent formed of propylene glycol at -10°C with stirring at 750 rpm.

[0213] The nicotine composition of Example 1 is a liquid tobacco extract obtained directly from an extraction process at a temperature of 130 degrees Celsius for 3 hours. The nicotine composition provides optimized levels of desired flavor compounds such as β-damascenon...

Embodiment 2

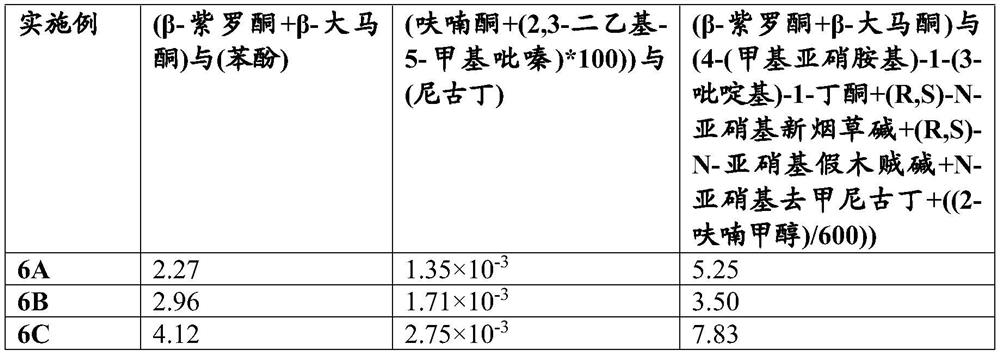

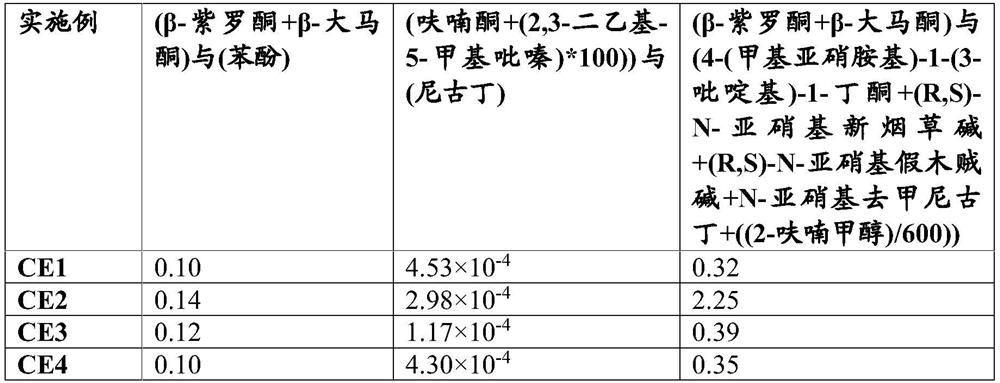

[0215] This example provides two nicotine compositions according to the invention, both of which are concentrated tobacco extracts obtained by extraction at a temperature of 130 degrees Celsius for a period of 3 hours, followed by Obtained by a drying step to reduce the moisture level of the liquid tobacco extract to about 6%. The concentrated tobacco extract is then used directly to form a nicotine composition. In both nicotine compositions, the weight ratio of (β-ionone+β-damascenone) to (phenol) is greater than 0.25, and (furanone+(2,3-diethyl-5-methylpyrrole) The weight ratio of oxazine)*100)) to (nicotine) is greater than 5×10 -4 .

Embodiment 2a

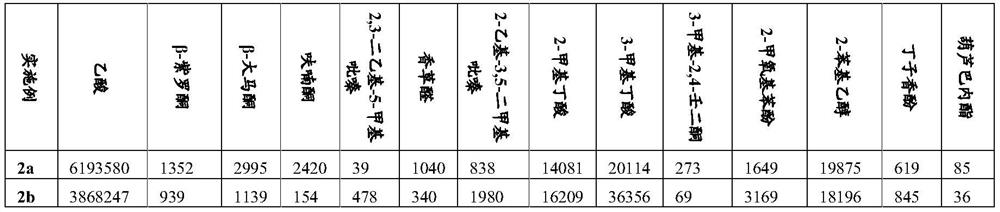

[0217] Example 2a relates to a concentrated tobacco leaf extract derived from flue-cured tobacco material. The content of the liquid tobacco extract of embodiment 2a is as follows:

[0218] ■Nicotine: 0.53%w / w

[0219] ■ Propylene Glycol: 91.8% w / w

[0220] ■Water: 6.3% w / w

[0221] ■ Balance (including fragrances detailed in Table 1 below): 1.57% w / w

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com