Multi-operation-mode modular continuum robot

A modular and continuum technology, applied in the field of robotics, can solve the problems that the robot can only be used as a mechanical arm, the user cannot independently modularize the assembly, and the drive components are bulky, etc., to achieve light structure, simple structure, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

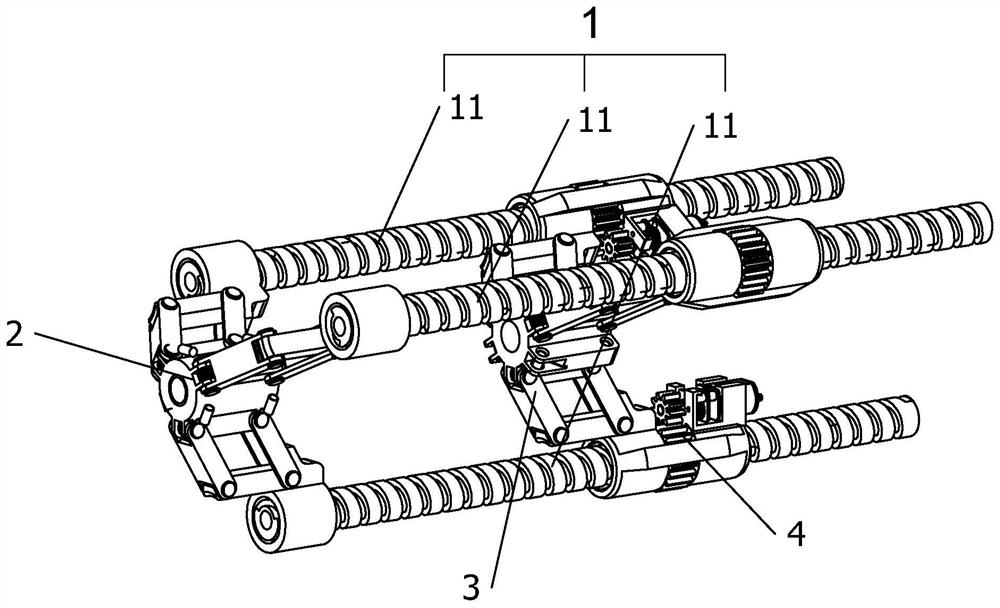

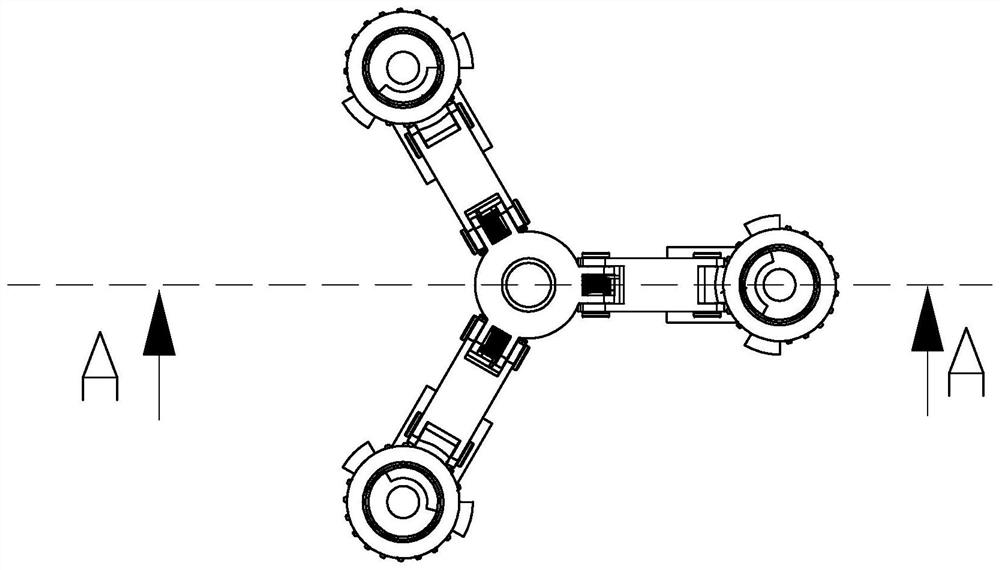

[0037] Embodiment 1 The continuum robot is used as a mobile robot (a section of the torso assembly)

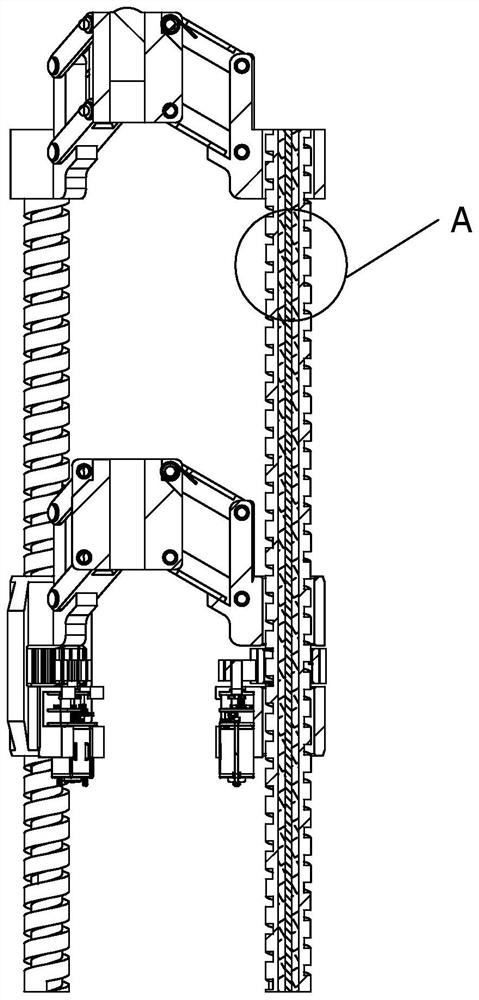

[0038] Such as Figure 1-5 As shown, the present invention includes a first base 2, a second base 3, a trunk assembly 1 and a drive assembly 4, the first base 2 includes a first connecting cylinder 21, three four-bar structures one 22 and three first fixed terminals 23 , the three four-bar structures 22 are evenly spaced and fixed on the circumferential surface of the first connecting cylinder 21 .

[0039] Flexible screw rod 11 comprises hollow bellows 111, foam interlayer pipe 112 and glass fiber rod 113, and foam interlayer pipe 112 is arranged in the chamber of hollow bellows 111, and glass fiber rod 113 is arranged in the chamber of foam interlayer pipe 112, and foam interlayer pipe The outer diameter of 112 is equal to the inner diameter of the hollow bellows 111, the outer diameter of the glass fiber rod 113 is equal to the inner diameter of the foam interlayer tube 11...

Embodiment 2

[0047] Embodiment 2 The continuum robot is used as a mobile robot (two-section torso assembly)

[0048] Such as Figure 9 As shown, the difference from Embodiment 1 is that the present invention includes a first base 2, two second bases 3, two trunk assemblies 1 and two drive assemblies 4, and the front end of the previous trunk assembly 1 is fixed A first base 2, a second base 3 is used to connect the two trunk assemblies 1, the previous trunk assembly 1 can move in the second base 3, and the front end of the latter trunk assembly 1 is connected to the second base 3. The second base 3 is fixed, and the rear trunk assembly 1 is connected with another second base 3 and can move in the second base 3 .

[0049] Such as Figure 10 and Figure 11 , the second base 3 includes a second connection cylinder 31, six four-bar structures two 32, three drive terminals 33 and three second fixed terminals 34, and the six four-bar structures two 32 are evenly fixed on the second The perip...

Embodiment 3

[0054] Embodiment 3 The continuum robot is used as a mechanical arm (two-section trunk assembly)

[0055] Such as Figure 9 and Figure 16 As shown, the difference between this embodiment and embodiment 2 is that the second base 3 at the end can be fixed on the connecting frame 6 when the present embodiment is used, and the present invention can be installed on the connecting frame by means of hoisting. 6, add an adsorption device at the front end of the first base 2, such as an electromagnet, a mechanical claw or a vacuum chuck 5, to realize the grasping of objects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com