Enamel spraying equipment for enameled tank of reaction kettle

An enamel tank and reaction kettle technology, which is applied to the inner wall enamel field of an open type reaction kettle, can solve the problems of large physical injury, high labor intensity, low production efficiency, etc., and achieves safe operation mode, stable product quality, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

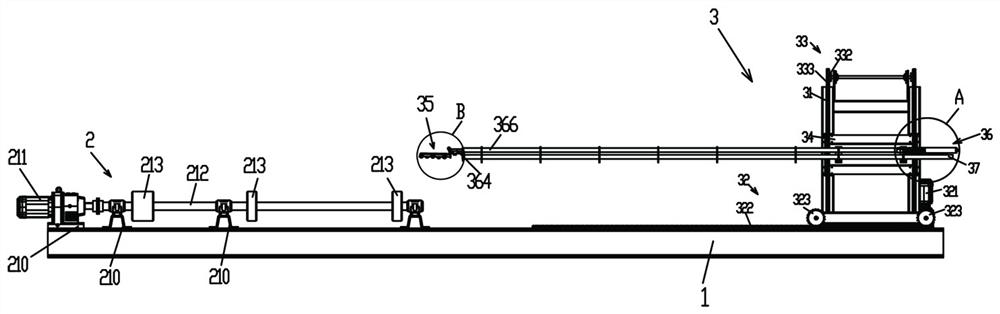

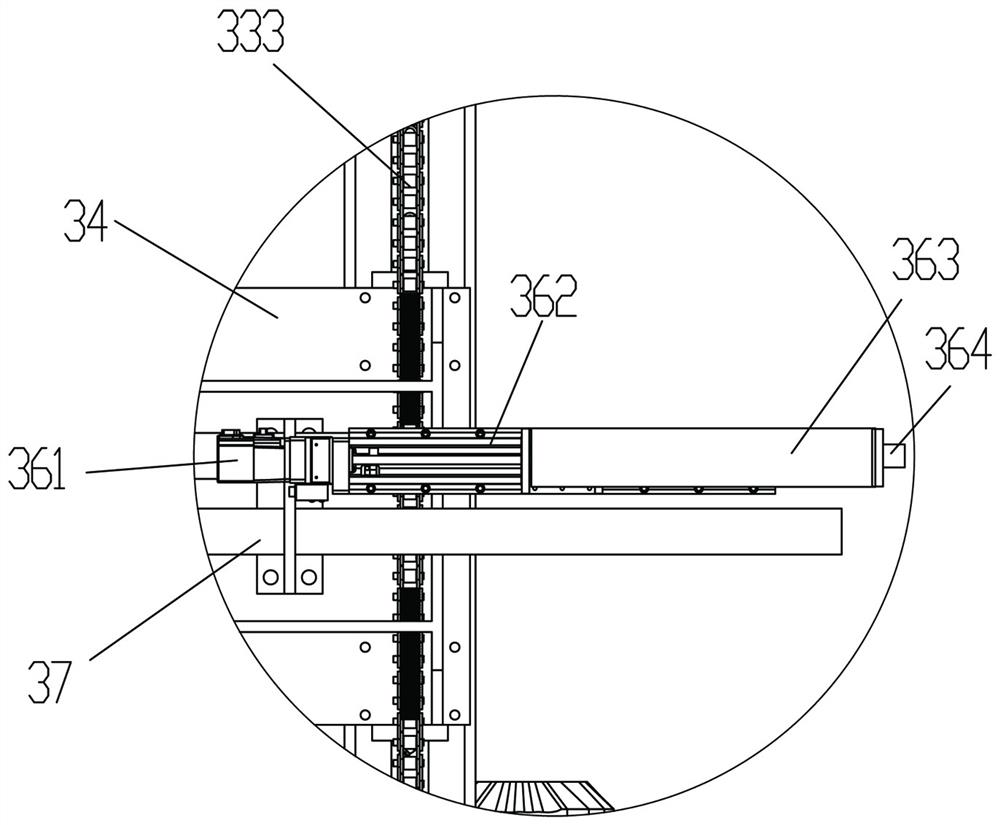

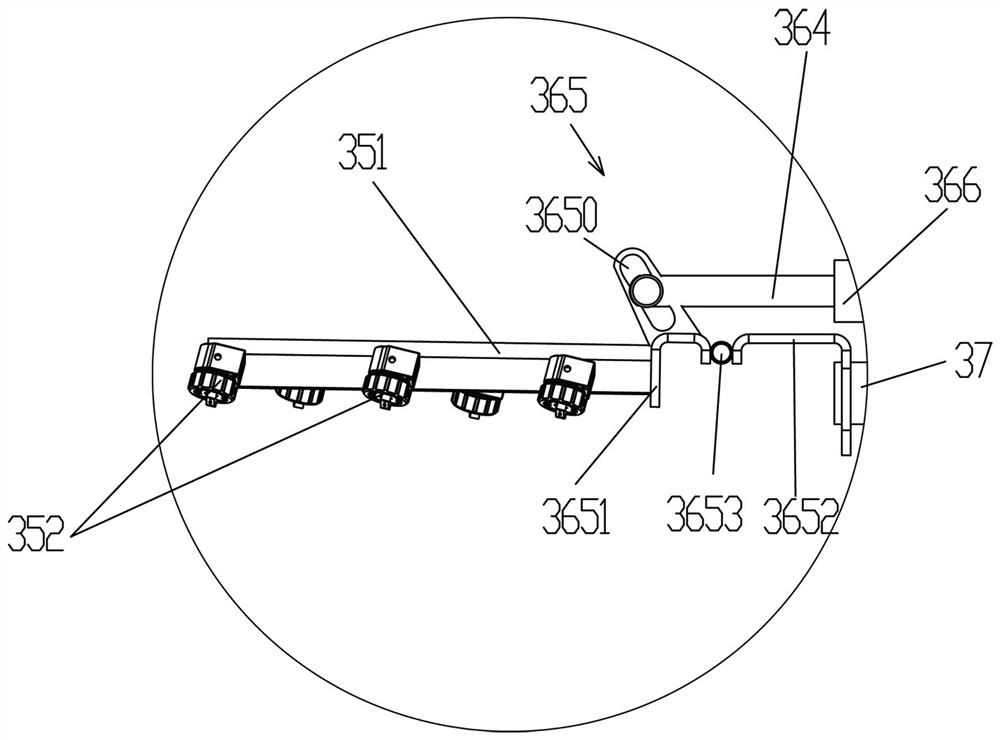

[0025] See Figure 1 to Figure 8 , Figure 1 to Figure 8 Disclosed is an embodiment of a reaction kettle enamel tank spraying equipment, a reaction kettle enamel tank spraying equipment, including a base 1, and an enamel tank rotating mechanism 2 and an automatic spray gun mechanism 3 are respectively provided at both ends of the base. The automatic spray gun mechanism 3 includes a frame 31, a transfer assembly 32, an elevating assembly 33 positioned on the frame 31, a connecting plate 34 that is positioned on the elevating assembly 33 and driven by the elevating assembly 33, and a swing angle assembly positioned on the connecting plate 34. 36. Glaze supply assembly 37, air supply assembly 38, and control system. The transfer assembly 32 is used to drive the frame 31 along the base 1 to approach or move away from the enamel pot rotation mechanism 2. The front end of the swing angle assembly 36 is hinged to a spray gun Assembly 35, and the spray gun assembly 35 is driven to sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com