Automatic paper angle bead binding device

A technology of automatic binding and paper corner protection, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of single function, low work efficiency, slow speed, etc., and achieve the effect of high degree of automation, improved efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

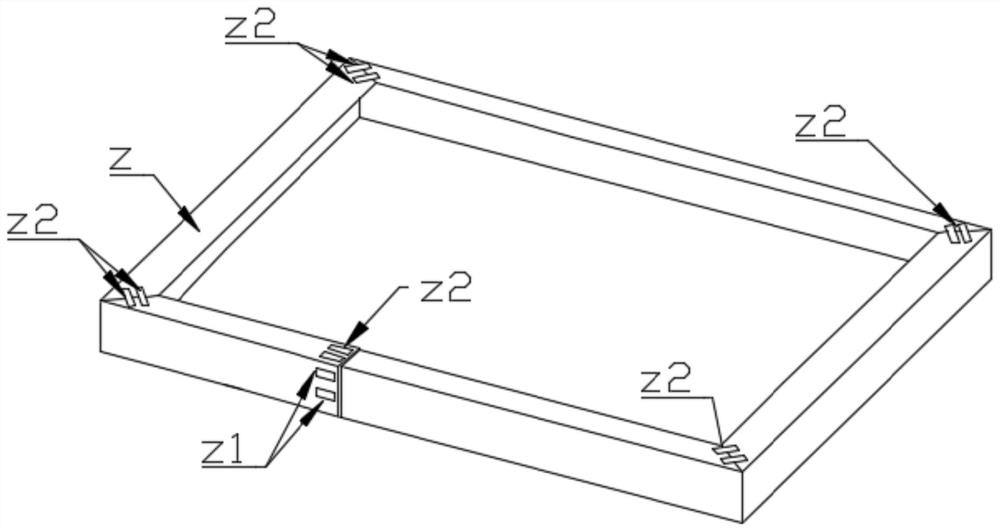

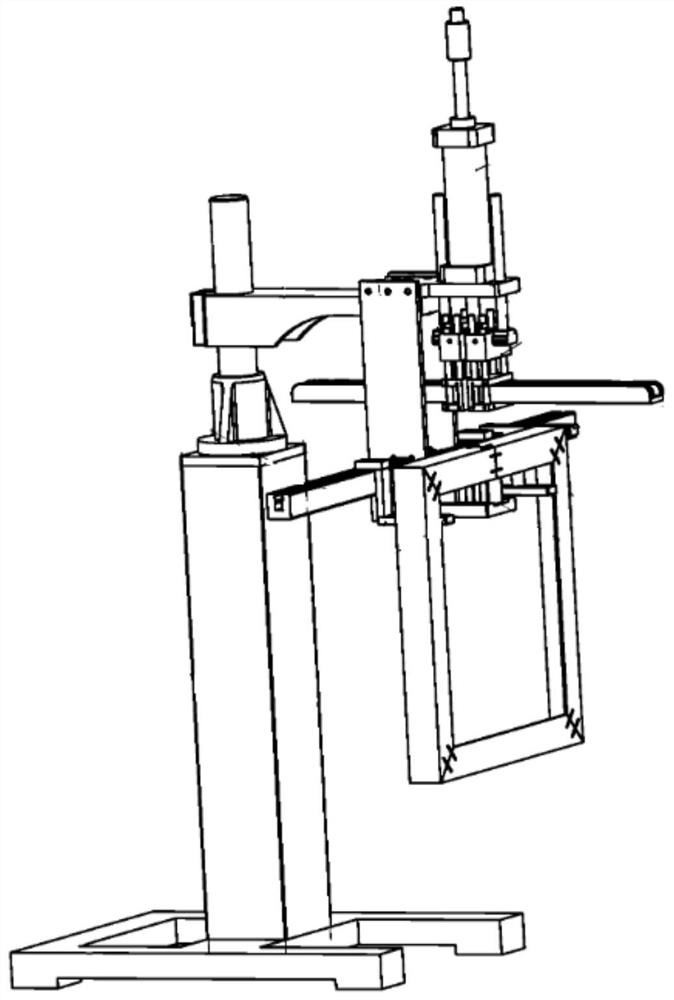

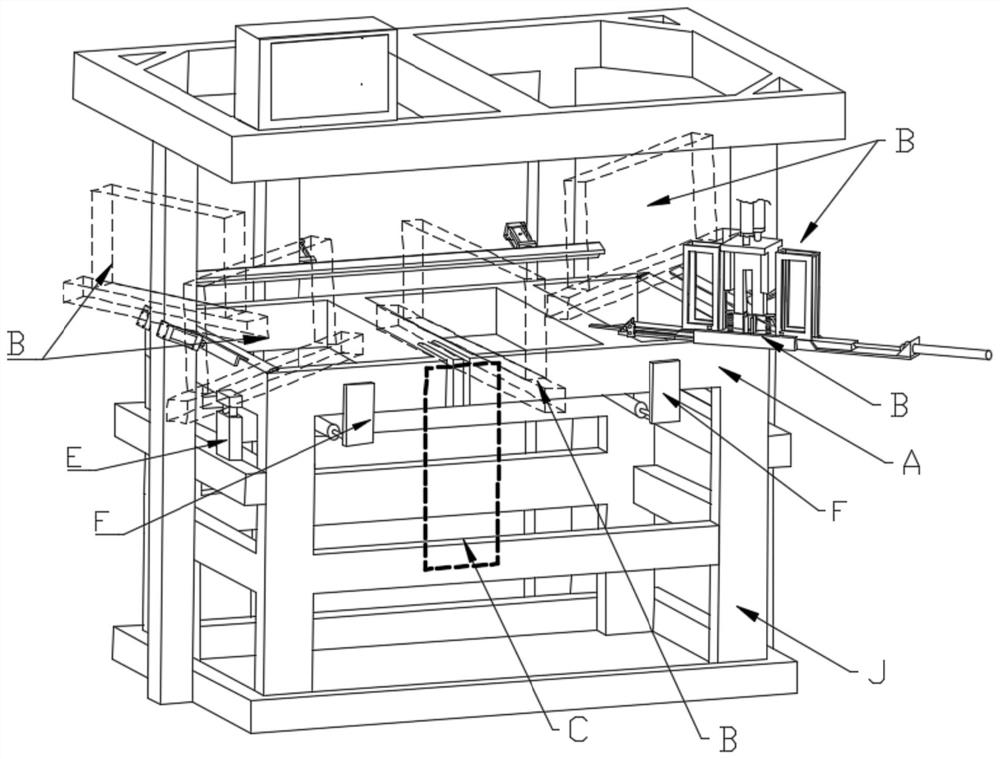

[0053] Such as image 3 As shown, this embodiment provides an automatic paper corner binding device, which includes a paper corner positioning platform A that is horizontally arranged on the frame J and is consistent with the shape of the paper corner after forming, and is installed on the paper corner positioning platform. A plurality of paper corner protection horizontal binding mechanisms B arranged on the same horizontal plane above the binding position, at least one set of paper corner protection side binding mechanisms arranged on the side of the paper corner protection positioning platform and used for binding the side of the paper corner protection at the side where the head and tail overlap c.

[0054] When working, all the paper corner horizontal binding mechanism B simultaneously binds all the binding positions on the upper surface of the paper corner, and the paper corner side binding mechanism C binds the side of the paper corner, through the above two kinds of bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com