Aluminum pipe conveying mechanism for aluminum machining and construction method

A technology of conveying mechanism and construction method, which is applied in the direction of conveyor, manual conveying device, transportation and packaging, etc., which can solve the problems of time-consuming and laborious, increased construction cost, low construction efficiency, etc., and achieves convenient use, improved work efficiency and flexible use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

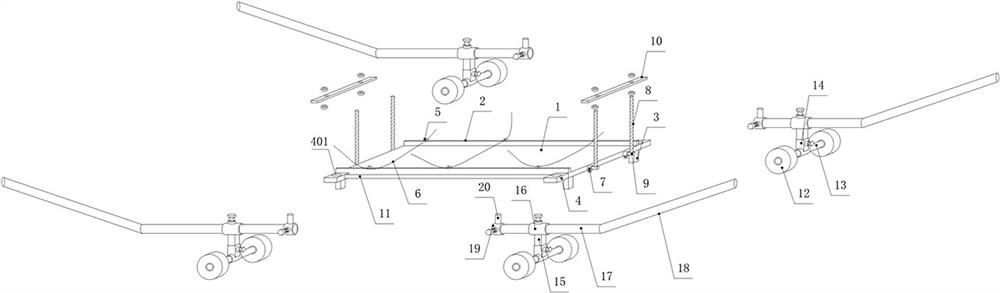

[0029] Example: see Figure 1-Figure 2 : An aluminum tube conveying mechanism for aluminum processing, comprising a support plate 1, legs 3 and ropes 6, the four corners of the bottom of the support plate 1 are provided with legs 3, and both sides of the support plate 1 are respectively provided with side baffles 2 , the side baffles 2 on each side are correspondingly provided with a positioning ring 5, and a rope 6 runs through between adjacent positioning rings 5; the two ends of the side of the support plate 1 are respectively provided with a connecting plate 4, and are connected A positioning hole 401 is dug on the plate 4, and a displacement assembly is arranged around the support plate 1, and is moved by the displacement assembly.

[0030] There are four connecting plates 4, two connecting plates 4 are respectively arranged at the two ends outside each side baffle plate 2, and connecting columns 11 are arranged between the two connecting plates 4 on each side, and the co...

Embodiment 2

[0038] Embodiment 2: The above-mentioned construction method of an aluminum tube conveying mechanism for aluminum processing specifically includes the following steps:

[0039] ①. Placement of pipelines:

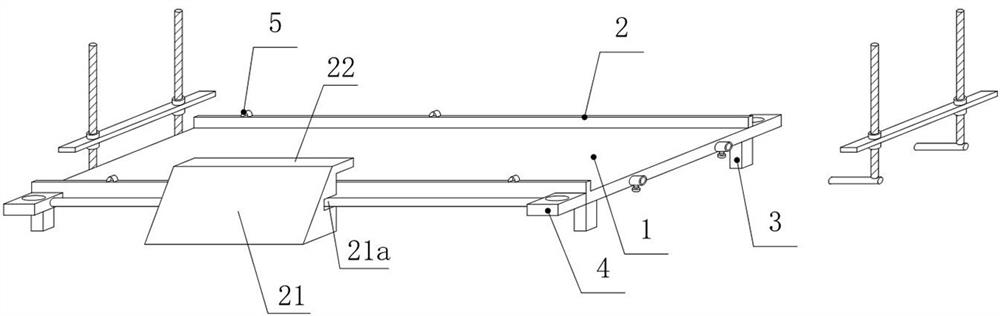

[0040] Place a guide plate 21 on both sides of the support plate 1, and set a rope on the positioning ring 5 between the two side baffles 2, and then pass the ends of the rope through the connecting column 11 and the side baffle respectively. In the space between, and press on the bottom of this side guide plate 21;

[0041] Use the guide plate 21 to move the pipes into the support plate 1 in sequence, and after the transfer is completed, put the guide plate 21 away, and tie the aluminum pipes with a rope;

[0042] ②, the installation of the limit device;

[0043] The inserting columns 9 are respectively inserted in the guide pipes at both ends of the support plate 1, and the horizontal plates 10 are sleeved on the two screw rods 8 at each end of the support plate 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com