Puffing composite line for clutch facing and preparation method and processing equipment of puffing composite line

The technology of clutch face plate and processing equipment is applied in the field of friction materials, which can solve the problems of high price, poor uniformity of puffed composite yarn, and high cost of puffed composite yarn, and achieves reduction of preparation cost, good composite uniformity, and stable output gas pressure. effect of sexual demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

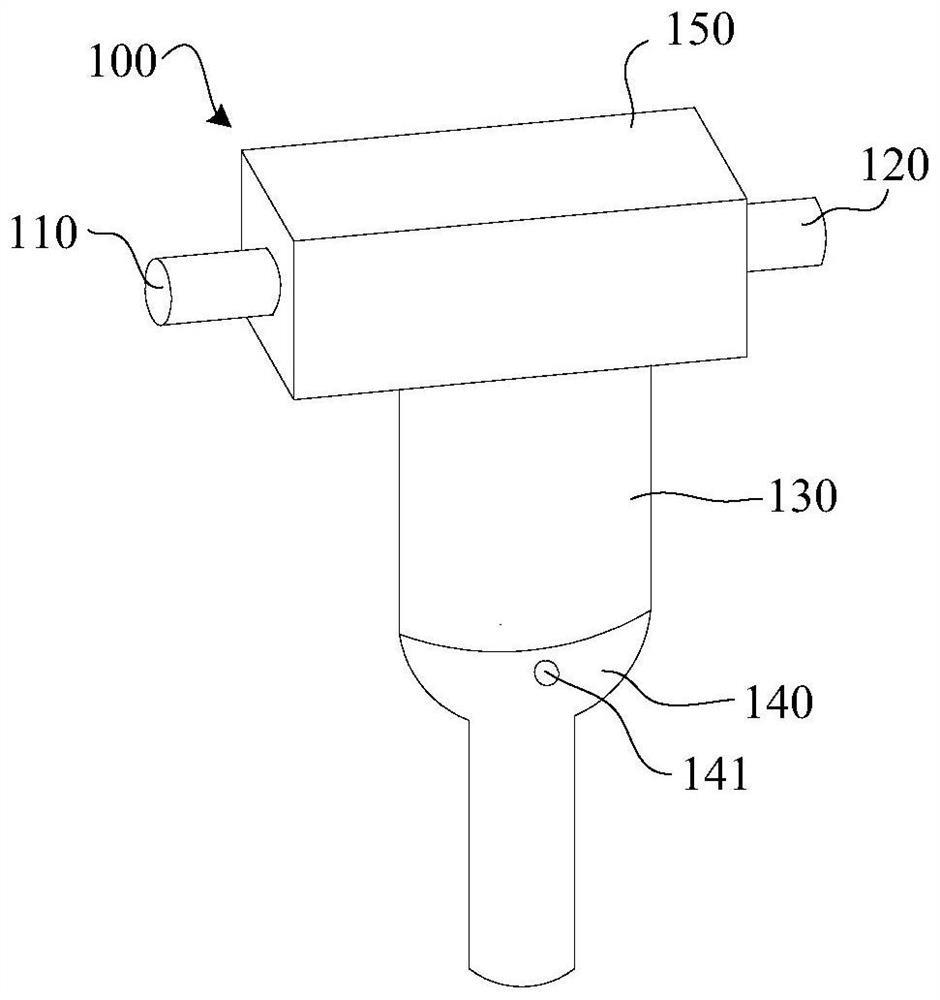

[0028] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

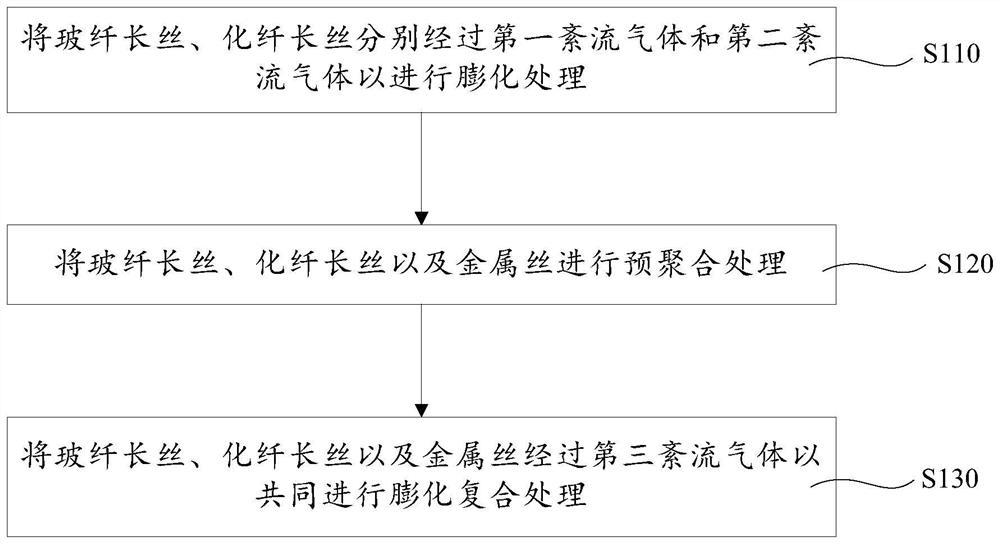

[0029] Please refer to the attached figure 1 , the application provides a method for preparing a puffed composite line for a clutch face, comprising:

[0030] S110: Pass the glass fiber filaments and chemical fiber filaments through the first turbulent gas and the second turbulent gas respectively for puffing treatment, the first turbulent gas is formed by the first high-pressure gas acting on the first puffing chamber, and the second turbulent gas The flowing gas is formed by the second high-pressure gas acting in the second expansion chamber;

[0031] S120: pre-polymerizing glass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com