Nondestructive testing method for appearance and roughness of inner surface of deep hole

A non-destructive testing and internal surface technology, applied in the field of precision measurement, can solve the problems of difficult detection of surface morphology and roughness, and achieve the effect of easy peeling off the surface of the workpiece, simple detection and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

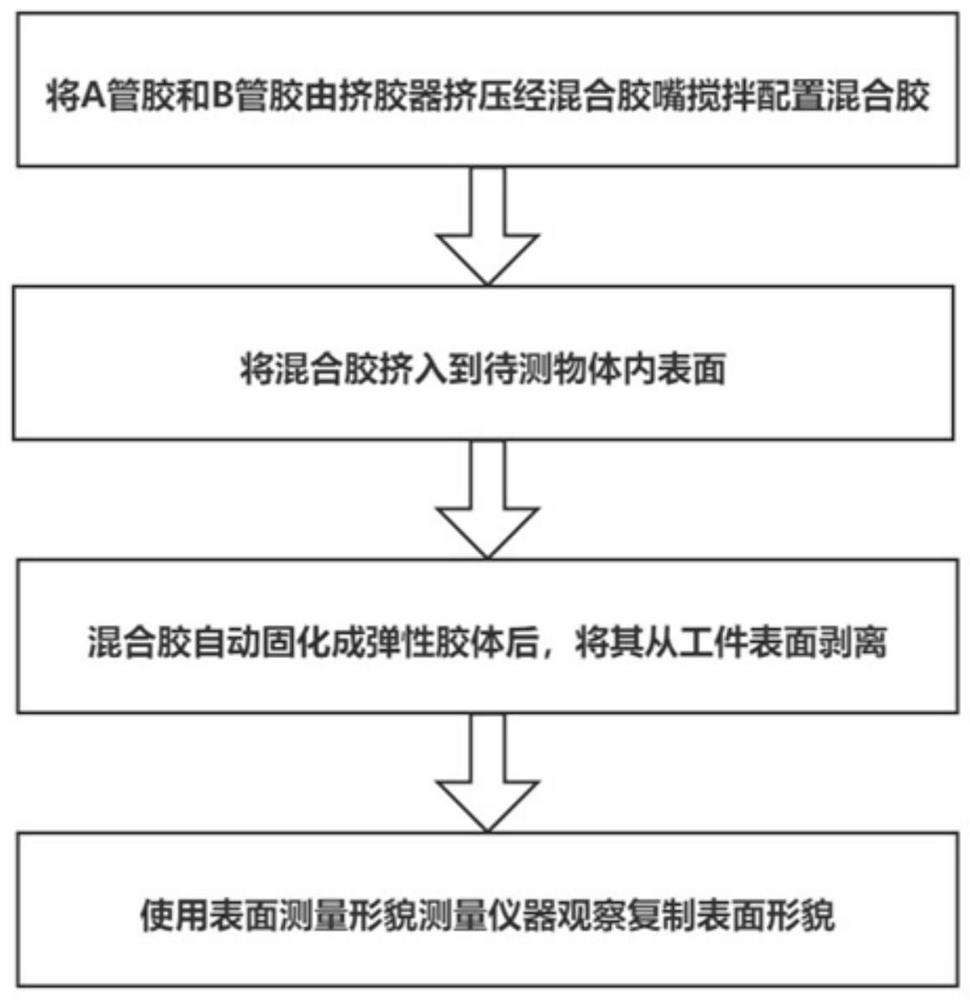

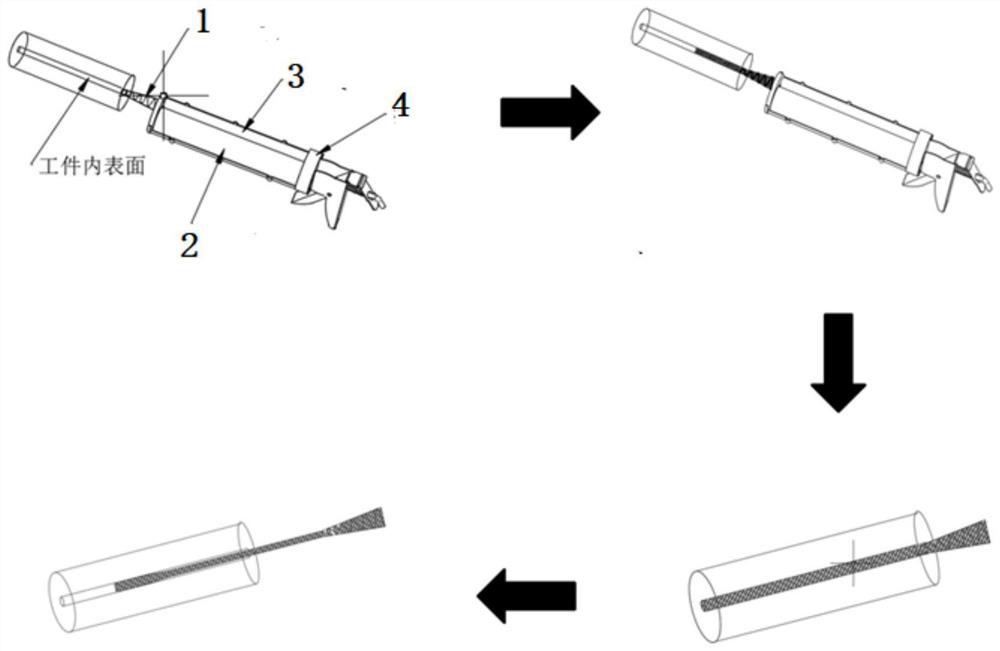

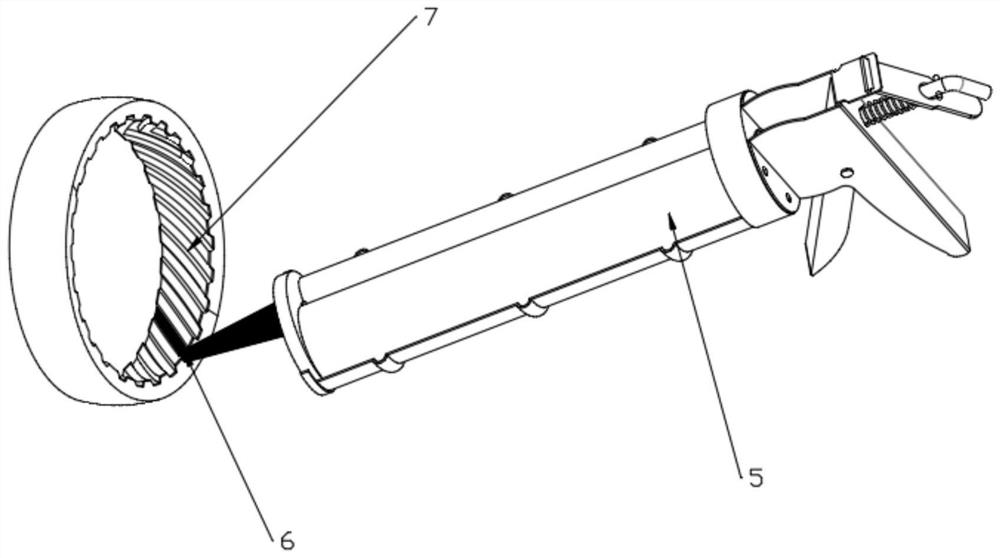

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. A non-destructive testing method for deep hole inner surface topography and roughness, the composition system of the present invention is as follows figure 2 As shown, it is realized based on the extrusion device 5. The extrusion device 5 includes a mixing glue 6, a glue extruder 4 and a mixing nozzle 1, wherein the mixing glue 6 is formed by mixing the A pipe glue 2 and the B pipe glue 3. The implementation process of the present invention is as figure 1 , figure 2 shown. The detection of the inner surface morphology of deep and slender holes includes the following steps:

[0027] When in use, use the extruder to extrude the mixed tube glue, the A tube glue 2 and the B tube glue 3 are fully mixed and stirred by the mixing nozzle 1, and then squeezed into the inner cavity surface 7 of the complex structure at the working temperature and working time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com