Creep fatigue life prediction method based on fused physical neural network

A technology of fatigue life prediction and neural network, applied in biological neural network models, neural learning methods, neural architectures, etc., can solve problems such as reliability doubts and lack of physical constraints, and achieve accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

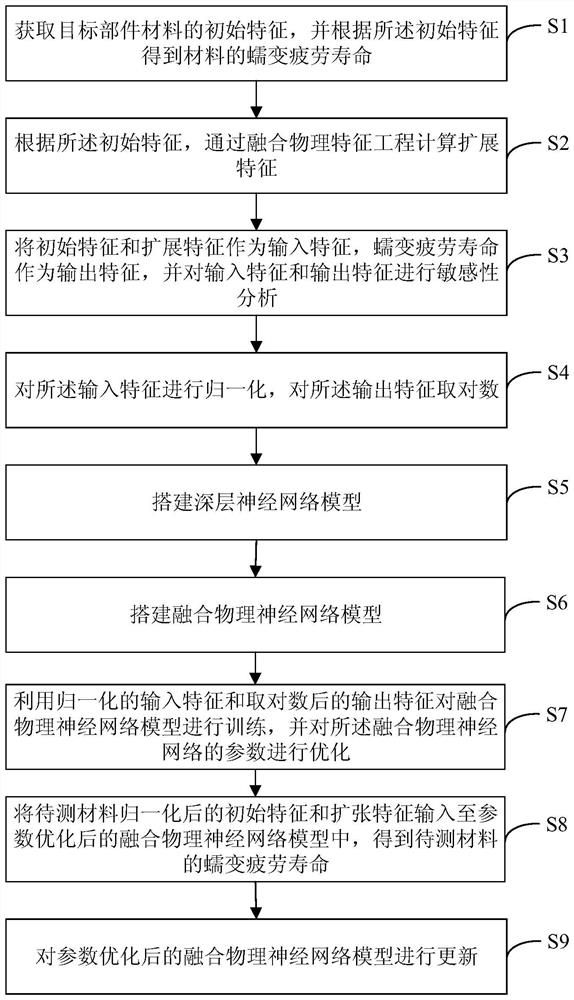

[0034] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

[0035] like figure 1 As shown, the present invention provides a kind of creep fatigue life prediction method based on fusion physical neural network, comprising the following steps:

[0036] S1: Obtain the initial characteristics of the target component material, including the loading conditions (strain amplitude Δε a , loading rate Temperature T, holding time t h ), chemical composition (C, Si, Mn, P, S, Ni, etc.) cf ;

[0037] The above initial characteristics and creep fatigue life can be obtained through experiments or literature research.

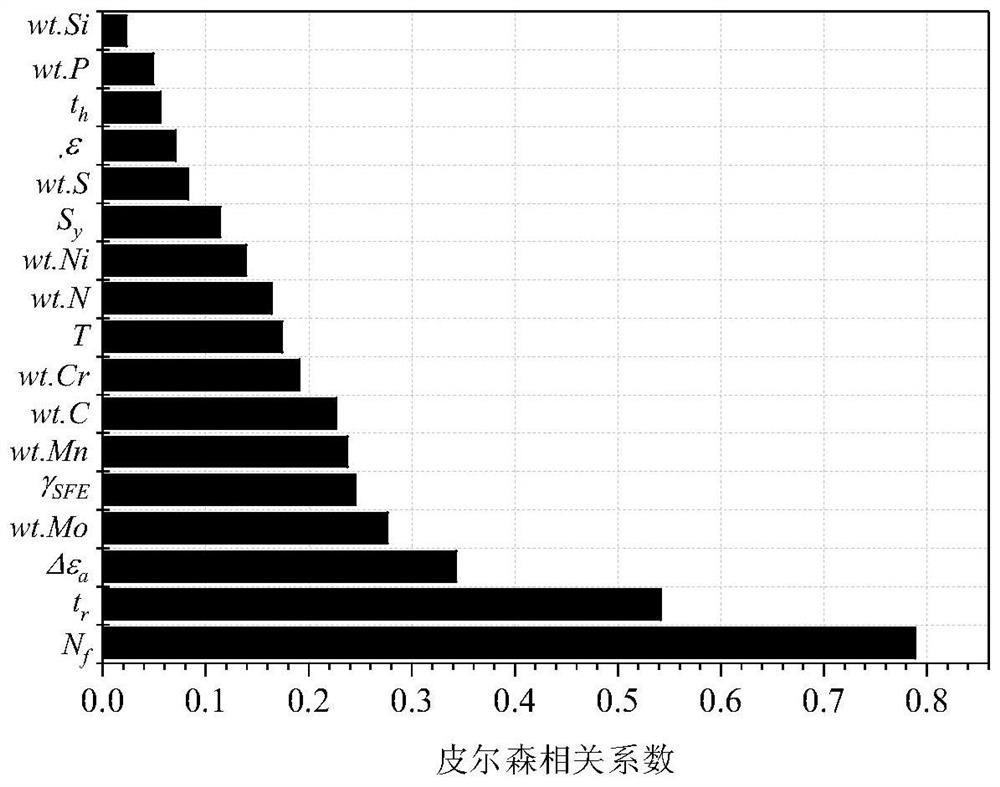

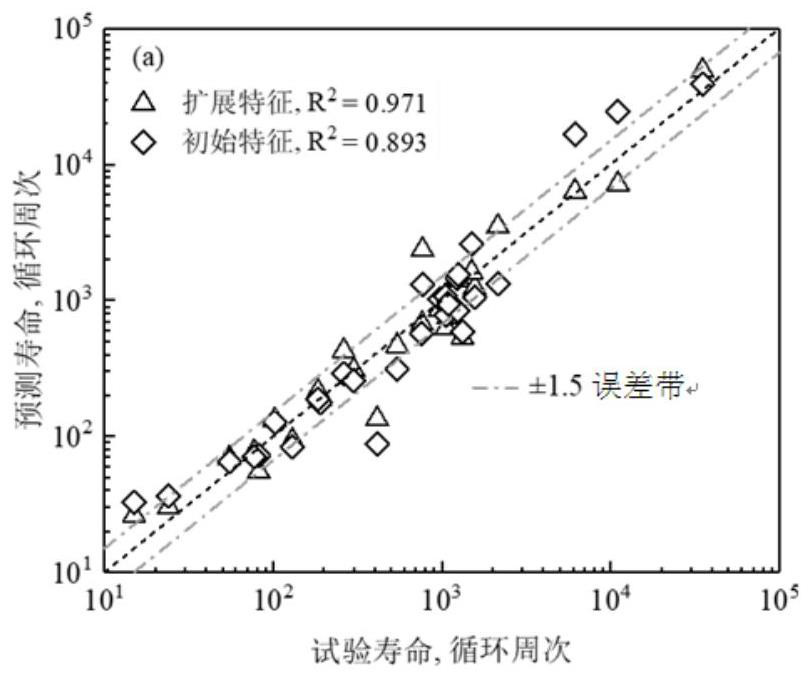

[0038] S2: Calculation of extended features by fusion physical feature engineering, including yield strength S y , stacking fault energy γ SFE , pure fatigue life N f and creep rupture life t r Wait;

[0039] Fusion physical feature engineering refers to the method of using the initial features a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com