Radiator for high-voltage switch cabinet

A high-voltage switchgear and radiator technology, which is applied in the cooling/ventilation of substations/switchgears, substation/switch layout details, electrical components, etc. Demand for large current-carrying current, effective heat dissipation and cooling, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

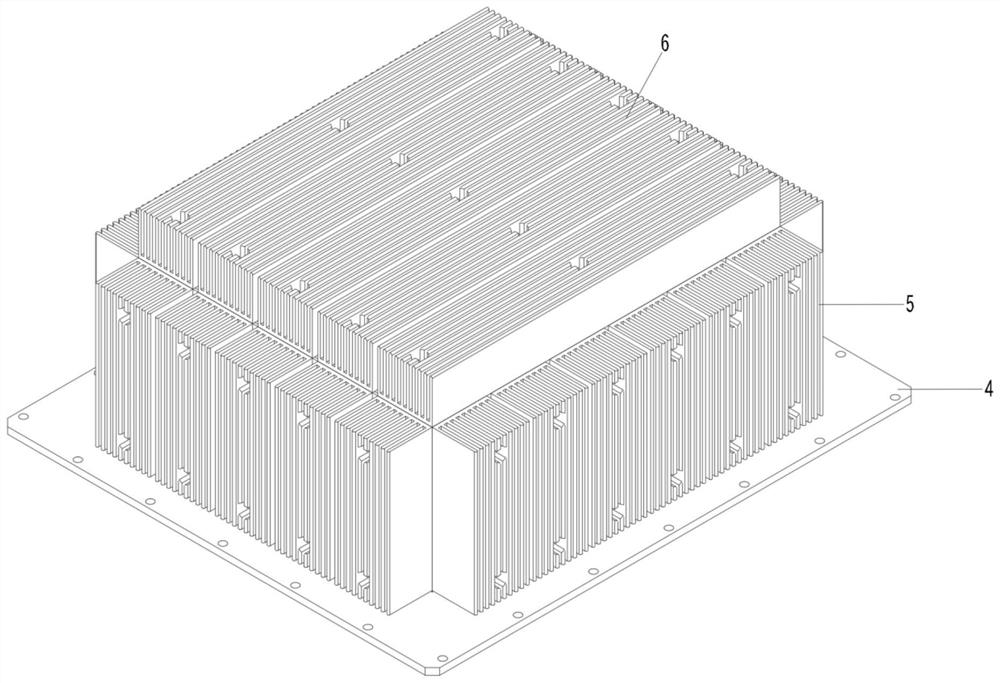

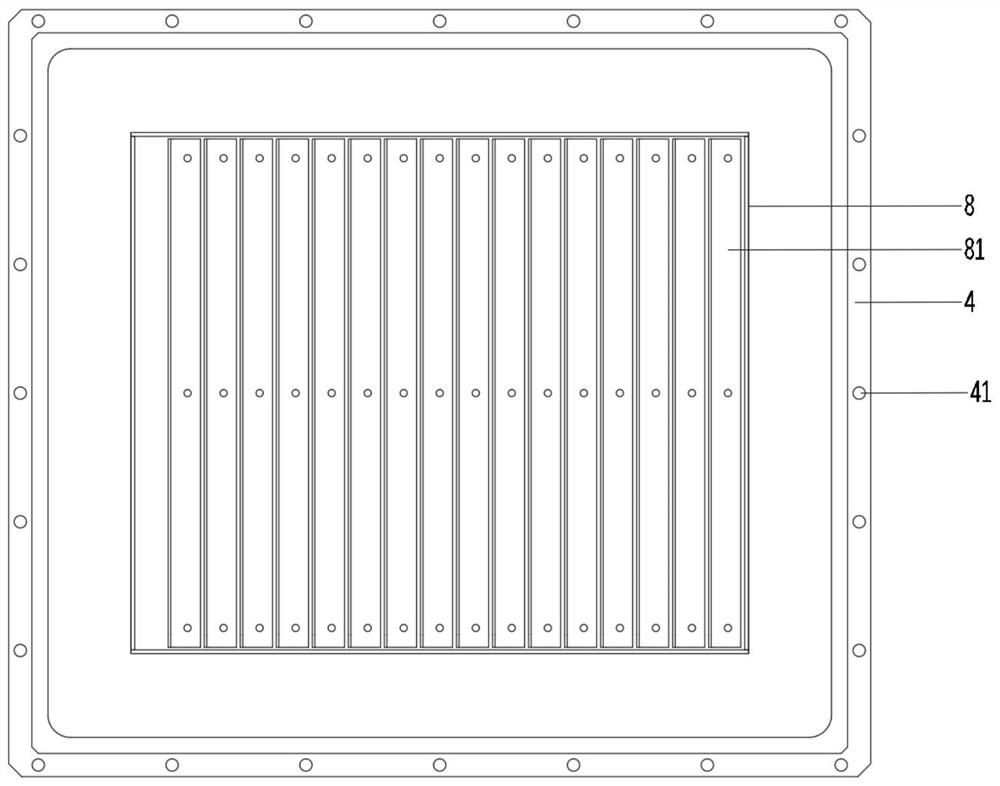

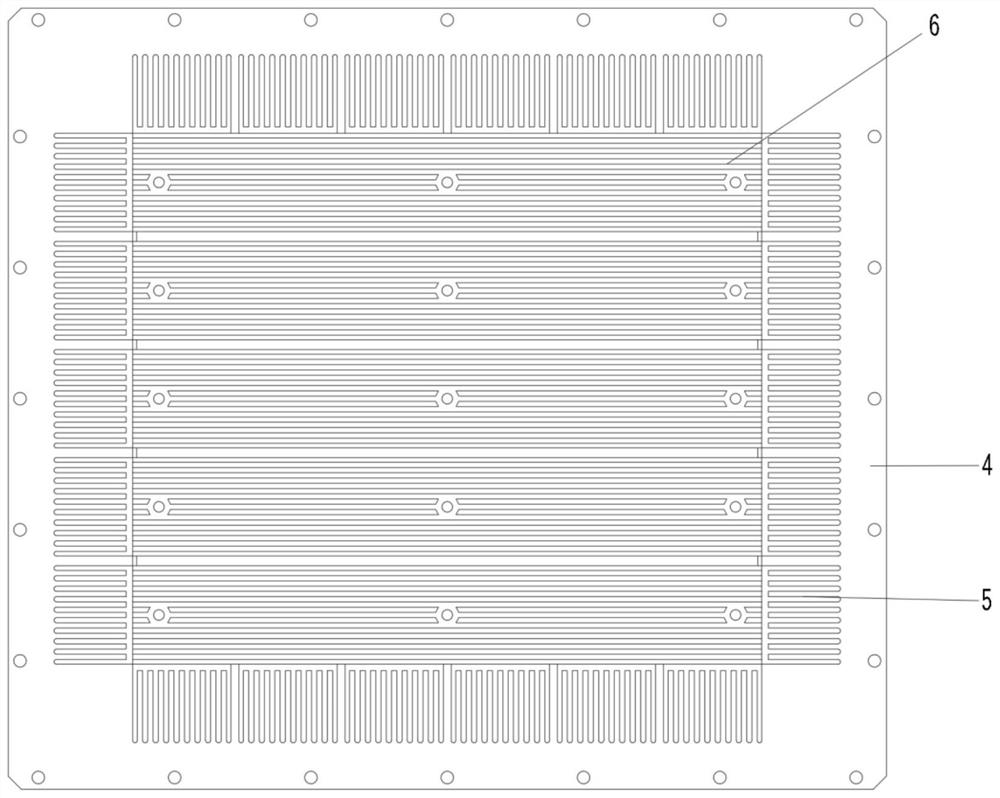

[0034] Such as Figure 1-5 As shown, the present invention provides a radiator for high-voltage switchgear, including a top plate 1, a first side plate 2, a second side plate 3 and a bottom plate 4, wherein the top plate 1 and the first side plate 2 and the second side The top of plate 3 is fixed;

[0035] The bottom ends of the first side plate 2 and the second side plate 3 are fixed to the top of the bottom plate 4, wherein a closed warehouse body 000 is formed between the top plate 1, the first side plate 2, the second side plate 3 and the bottom plate 4, There are two first side plates 2 and two second side plates 3 and they are arranged symmetrically so as to form an airtight warehouse body 000 between the top plate 1 and the bottom plate 4. In this embodiment, the warehouse body 000 is only airtight in a broad sense , is not completely airtight;

[0036] The first heat dissipation plate 5 is installed on the outer side of the first side plate 2 and the second side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com