Agricultural and pastoral forage carding and bundling integrated machine and bundling method thereof

A forage, farming and animal husbandry technology, applied in the agricultural and pasture forage combing and bundling integrated machine and its bundling field, can solve the problems of slow rotation of rollers, different forage specifications, easy entanglement of forage to the transmission structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

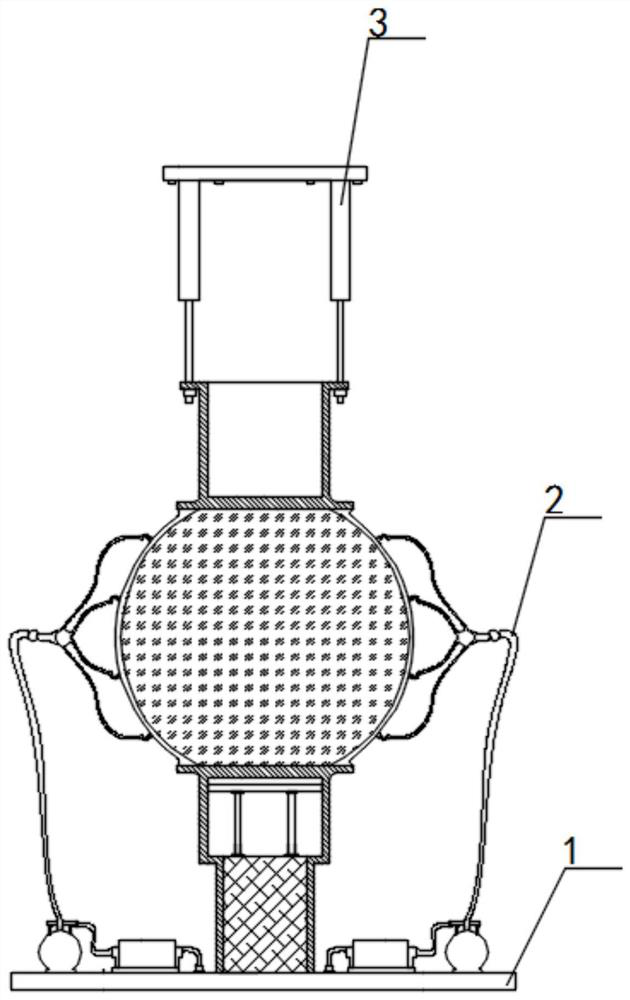

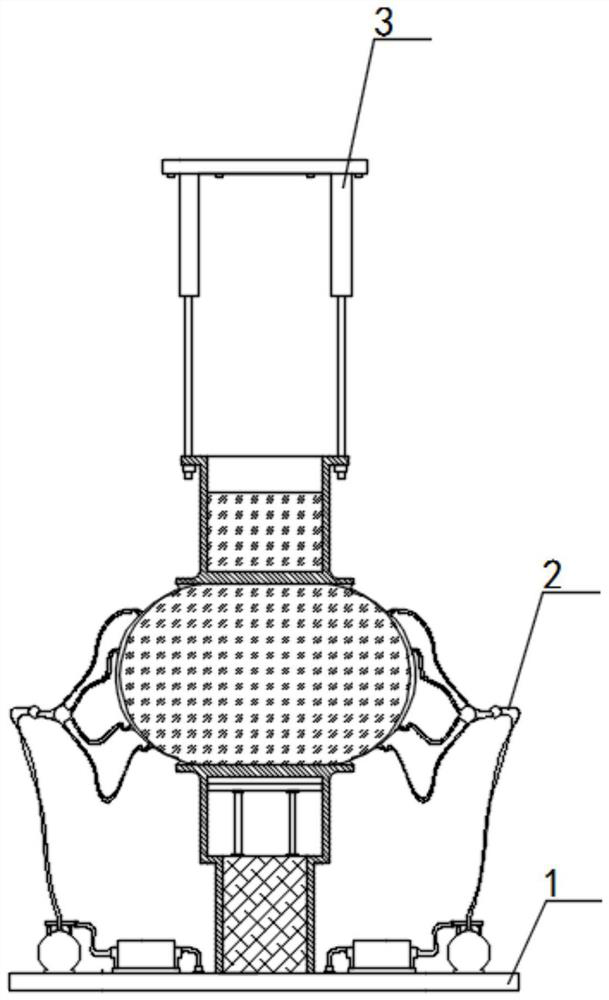

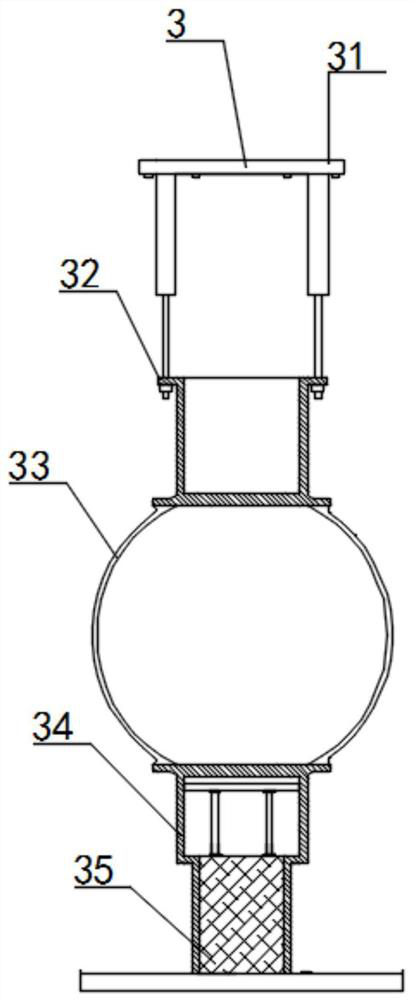

[0031] Such as Figure 1-3 As shown, the agricultural and animal husbandry forage material carding and bundling integrated machine includes a base 1 and a bundling device 3, the top of the base 1 is provided with a bundling device 3, and the bundling device 3 includes a hydraulic assembly 31, a mold 32, a rubber spherical shell 33, The fixed seat 34 and the vibrating assembly 35, the top of the base 1 is vertically fixed with the fixed seat 34, the fixed seat 34 is sleeved and fixedly connected with the vibrating assembly 35; A mold 32 is provided, and the port at the mold 32 is connected to the upper port at the rubber spherical shell 33; the left and right sides of the rubber spherical shell 33 are provided with a carding device 2, and one end of the carding device 2 is inserted through the rubber spherical shell 33; A hydraulic assembly 31 is arranged above the mold 32, and two hydraulic rods at the hydraulic assembly 31 are symmetrically connected to the edge of the outer ...

Embodiment 2

[0035] Such as Figure 1-4As shown, the agricultural and pasture material combing and bundling integrated machine, the vibrating assembly 35 includes a hose 351, a support frame 352, an impeller 353, a sphere 354, a contact plate 355, a ball tube 356, a connecting pipe 357 and a circular box 358, and a fixed seat 34 A support frame 352 is fixed in the inner sleeve, and a circular box 358 is arranged symmetrically inside the support frame 352, and an impeller 353 is rotatably connected to the circular box 358; The protruding end is sleeved with a hose 351, and the hose 351 is connected to the carding device 2; the top of the support frame 352 is symmetrically provided with a bulb 356, and the bulb 356 and the connecting tube 357 are connected with ports; the bulb 356 A ball groove is arranged inside, and the cavities from the ball groove to the connecting pipe 357 are connected; a ball 354 is set in the ball groove in the ball pipe 356, and a touch plate 355 is arranged above t...

Embodiment 3

[0038] Such as figure 1 , 2 , 5, 6 and 7, agricultural and animal husbandry forage material carding and bundling integrated machinery, carding device 2 includes intubation tube 21, collector 22, air pipe 23, air pump 24 and filter assembly 25, both sides of rubber spherical shell 33 are provided with assembly Four intubates 21 are arranged between the concentrator 22 and the rubber spherical shell 33, and the two ends of the four intubates 21 are connected to the rubber spherical shell 33 and the concentrator 22 respectively; the other end of the concentrator 22 is connected to Air pipe 23 is arranged, and both sides of fixed base 34 are symmetrically connected with air pump 24 at the top of base 1, and one end of air pump 24 is connected with vibrating assembly 35; the other end of air pump 24 is fixedly connected with filter assembly 25 at the top of base 1, The air pump 24 is connected to the filter assembly 25, and the air pipe 23 is connected to the filter assembly 25; t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap