High-speed rail containerization tool

A container and tool technology, applied in the field of high-speed rail container tools, can solve problems such as inconvenience in use, and achieve the effects of portability, improved utilization, and full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

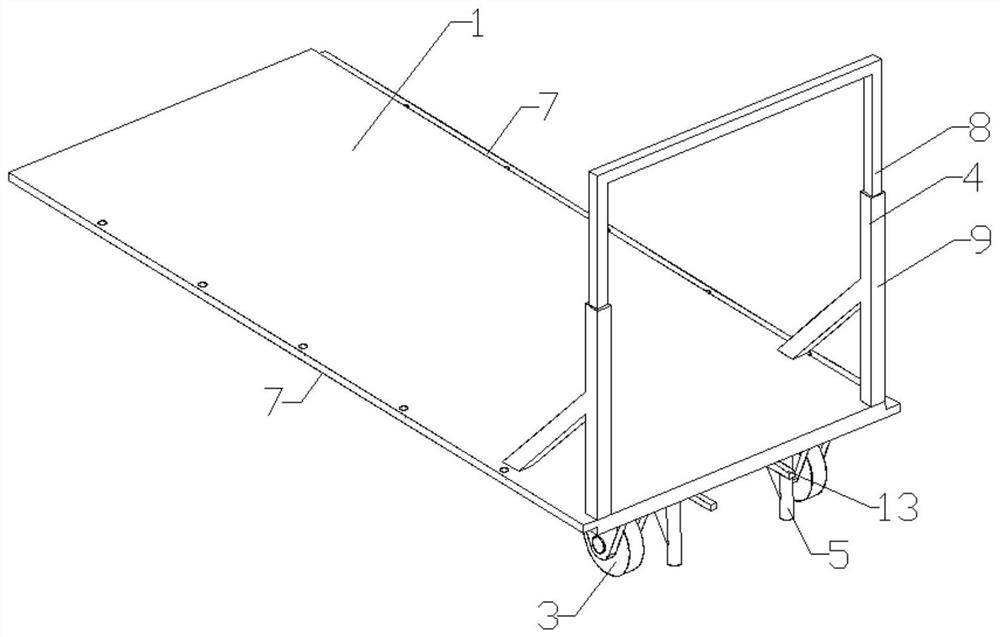

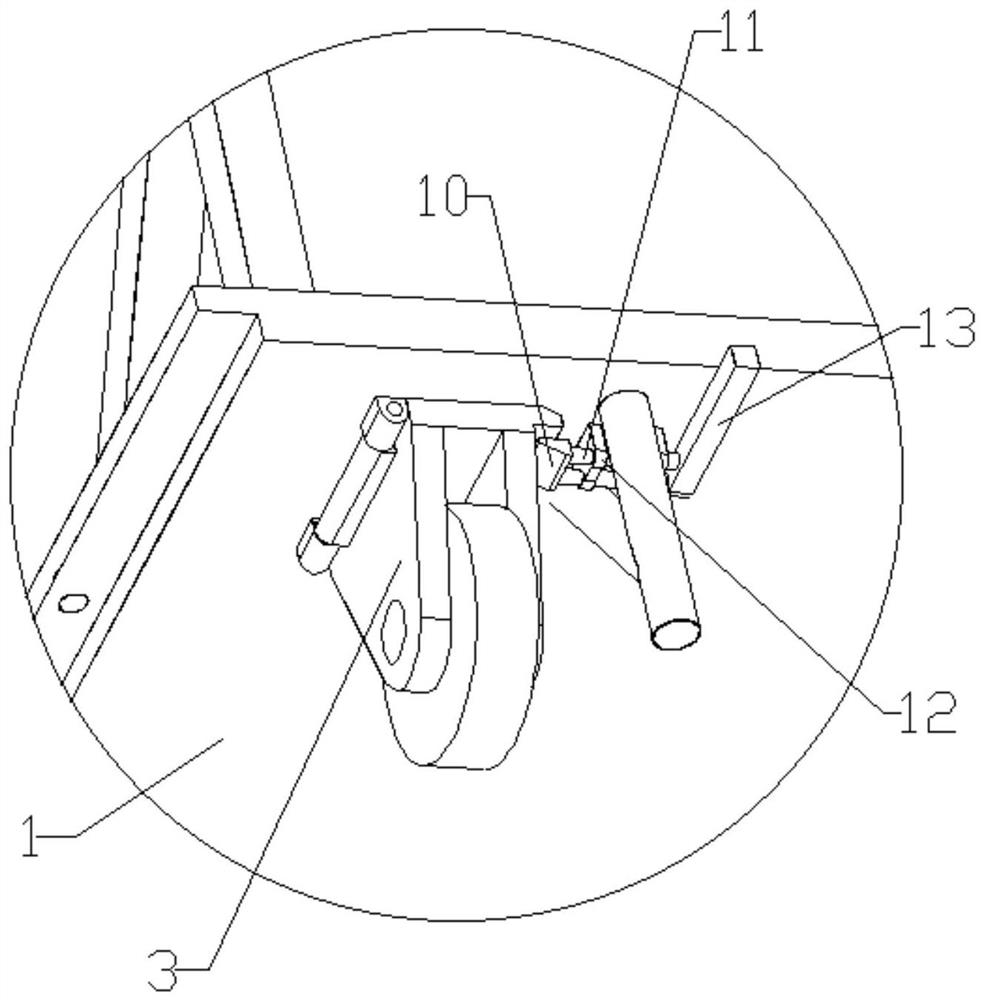

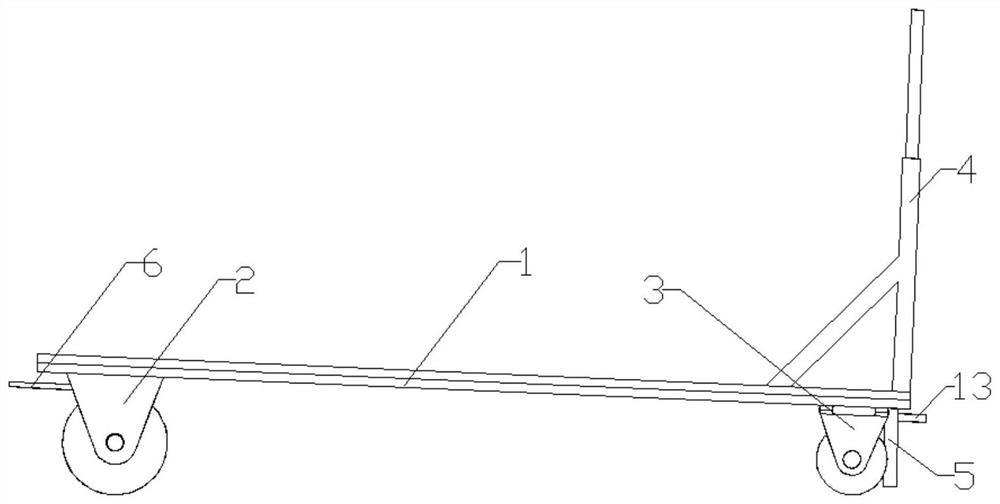

[0021] Such as figure 1 , figure 2 , image 3 As shown, a high-speed rail assembly tool includes a base plate 1, a movable wheel 2, a contraction wheel 3, and a telescopic handle 4. The movable wheel 2 is installed on one side of the bottom of the base plate 1, and the contraction wheel 3 is installed on the other side of the bottom of the base plate 1. On one side, the telescopic handle 4 is fixedly installed on the side of the base plate 1 close to the retractable wheel 3, and the telescopic handle 4 is lowered to be provided with a support column 5, and one side of the retractable wheel 3 is connected to the bottom of the base plate 1 through a hinge, and the retractable wheel One side of the 3 is connected to the bottom of the base plate 1 through the locking mechanism 6, the movable wheel 2 is installed on the central axis ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap