Energy-saving and environment-friendly sewage treatment system and sewage treatment method

A sewage treatment system, energy saving and environmental protection technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Equipment cost, easy to take out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

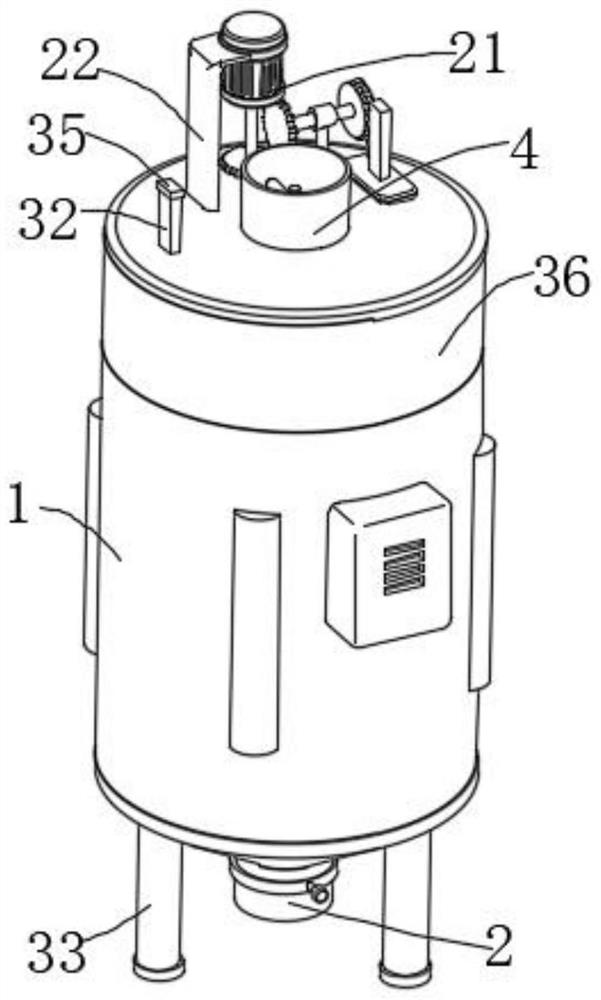

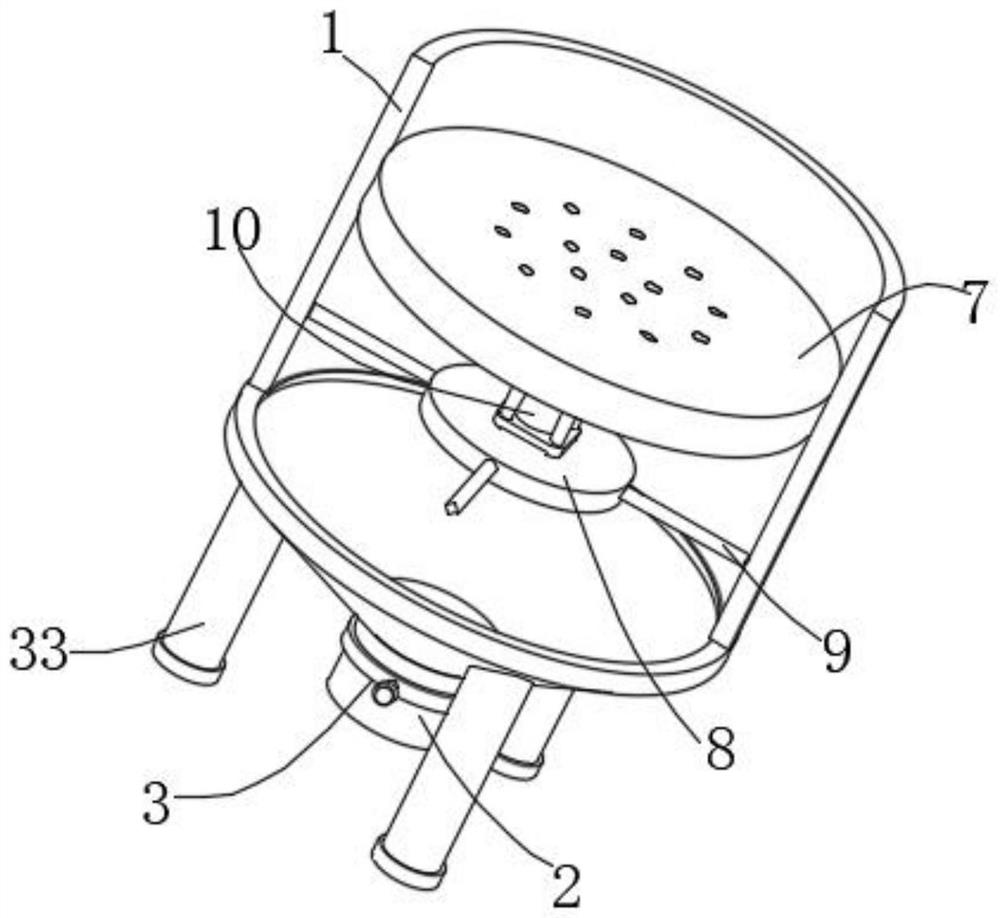

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6As shown, this embodiment proposes an energy-saving and environment-friendly sewage treatment system, including a lower casing 1 arranged horizontally, the bottom of the lower casing 1 is funnel-shaped, and a water outlet pipe 2 is fixed vertically on the bottom of the lower casing 1, and the water outlet pipe 2 A valve 3 is installed, an upper casing 36 is mounted on the upper end surface of the lower casing 1, and a water inlet 4 is vertically fixed on the upper wall of the upper casing 36, and the water inlet 4 is vertically provided with a valve extending into the lower casing 1. The main shaft 5, the main shaft 5 is installed on the inner wall of the water inlet 4 through a connecting piece, the connecting piece includes a collar 19 which is rotatably sleeved on the outer side wall of the main shaft 5, and the outer side wall of the collar 19 is connected to the water inlet 4 through the ...

Embodiment 2

[0039] The scheme in embodiment 1 is further introduced below in combination with specific working methods, see the following description for details:

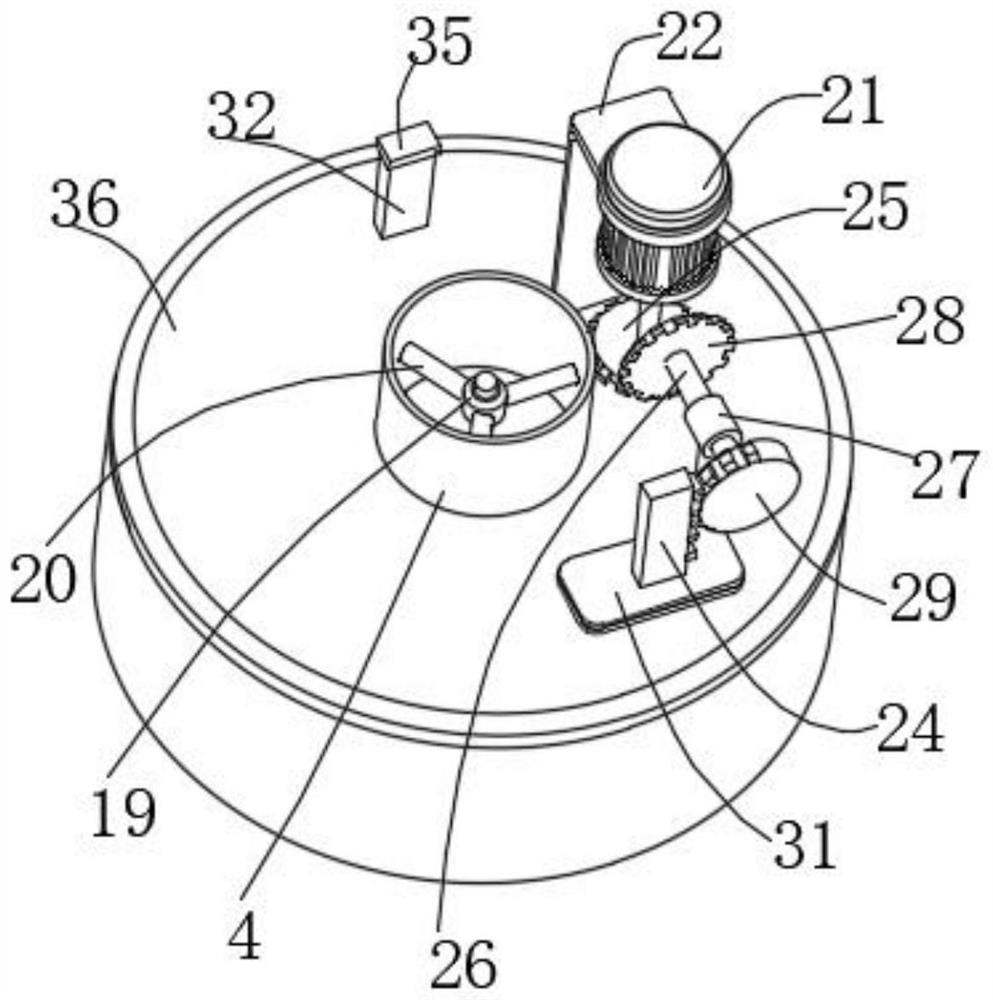

[0040] Such as figure 1 , image 3 , Figure 4 As shown, as a preferred embodiment, on the basis of the above method, the linkage mechanism includes a rack 24 fixed vertically on the upper end surface of the upper ring 16, the rack 24 moves through the upper housing 36, and the output shaft of the motor 21 An active helical gear 25 is fixedly sleeved horizontally on the outer side wall above the upper housing 36 , and a bracket 27 connected to the transmission shaft 26 is fixed vertically on the upper end of the upper housing 36 . The transmission shaft 26 is close to the drive shaft 25 . One end is vertically fixedly installed with a driven helical gear 28 meshed with the driving helical gear 25, and one end of the transmission shaft 26 away from the driven helical gear 28 is vertically fixedly installed with an incomplete ...

Embodiment 3

[0042] The schemes in Embodiment 1 and Embodiment 2 will be further introduced in combination with specific working methods, see the following description for details:.

[0043] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 As shown, as a preferred embodiment, on the basis of the above method, the length of the water blocking rod 12 is the same as the thickness of the mesh plate 7, and the plurality of water blocking rods 12 correspond to the meshes of the mesh plate 7 one by one, and the scraper 6 The upper end surface is inclined, the scraper 6 is fan-shaped at 90 degrees, and the length of the water blocking rod 12 is set to ensure that the scraper 6 will not collide with the water blocking rod 12 during the rotating operation, so as to ensure the realization of the function of the device. 12 can not only be used to control the opening and blocking of the mesh plate 7, but also can be used to clean the mesh of the mesh plate 7. The upper end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com