A Sectional Joint Structure of Prefabricated Underground Diaphragm Wall

A technology of underground diaphragm wall and joint structure, applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of poor stability, reduced use effect, unfavorable concrete pouring, etc., to strengthen the connection stability, reduce the impact of impact, Not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

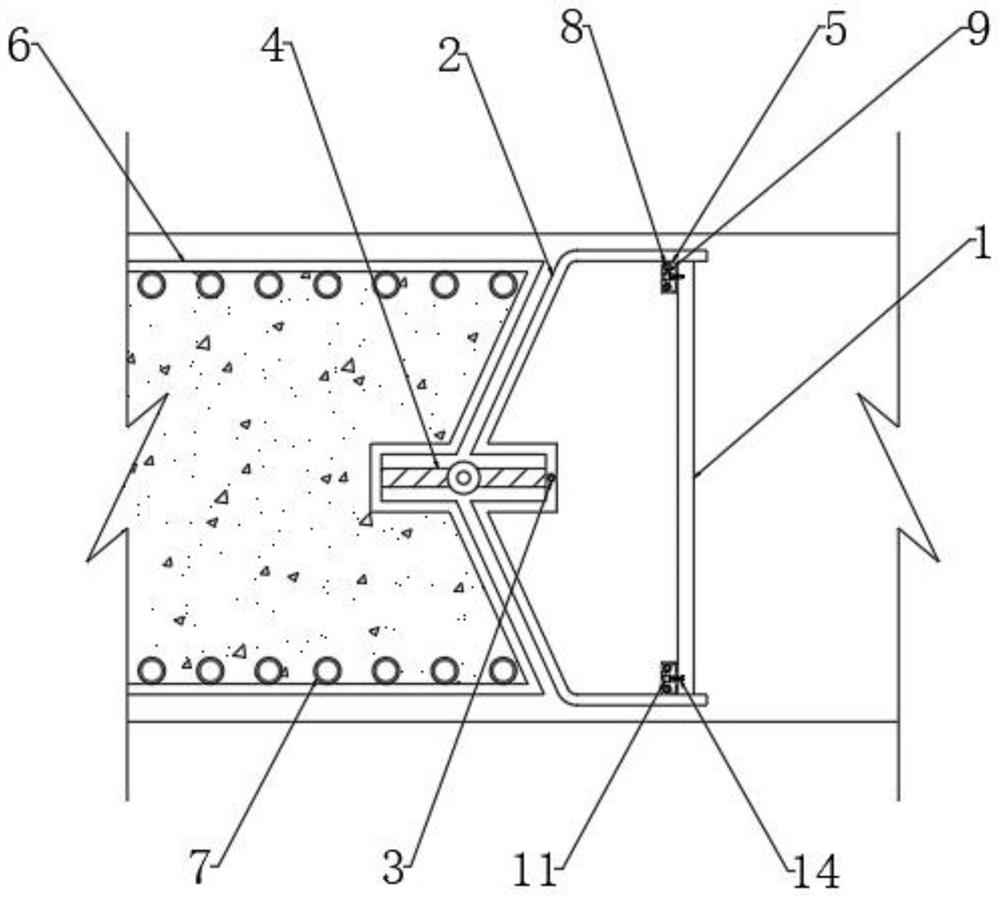

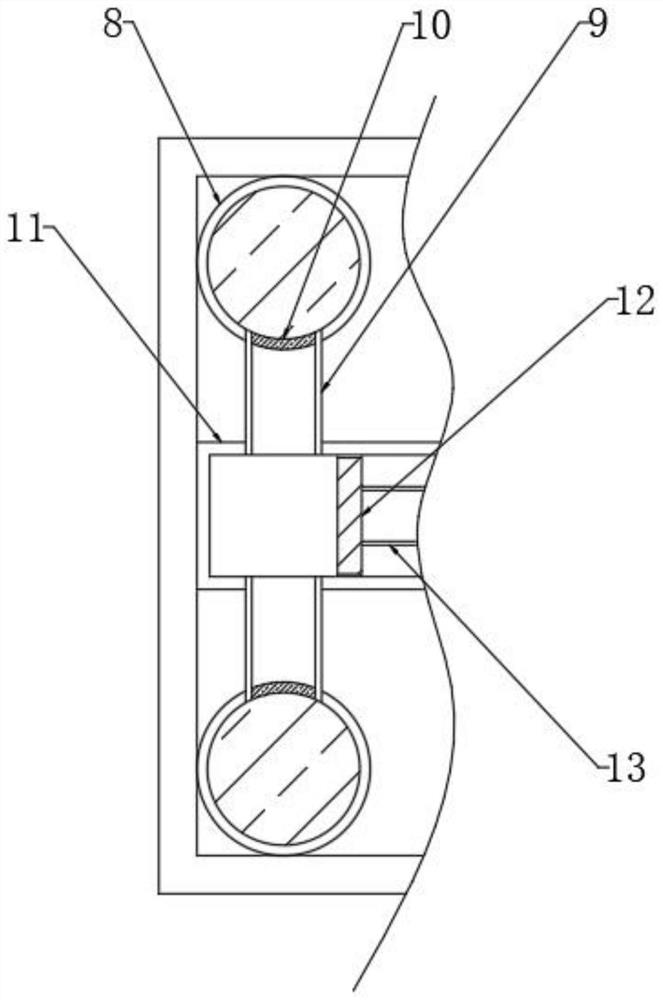

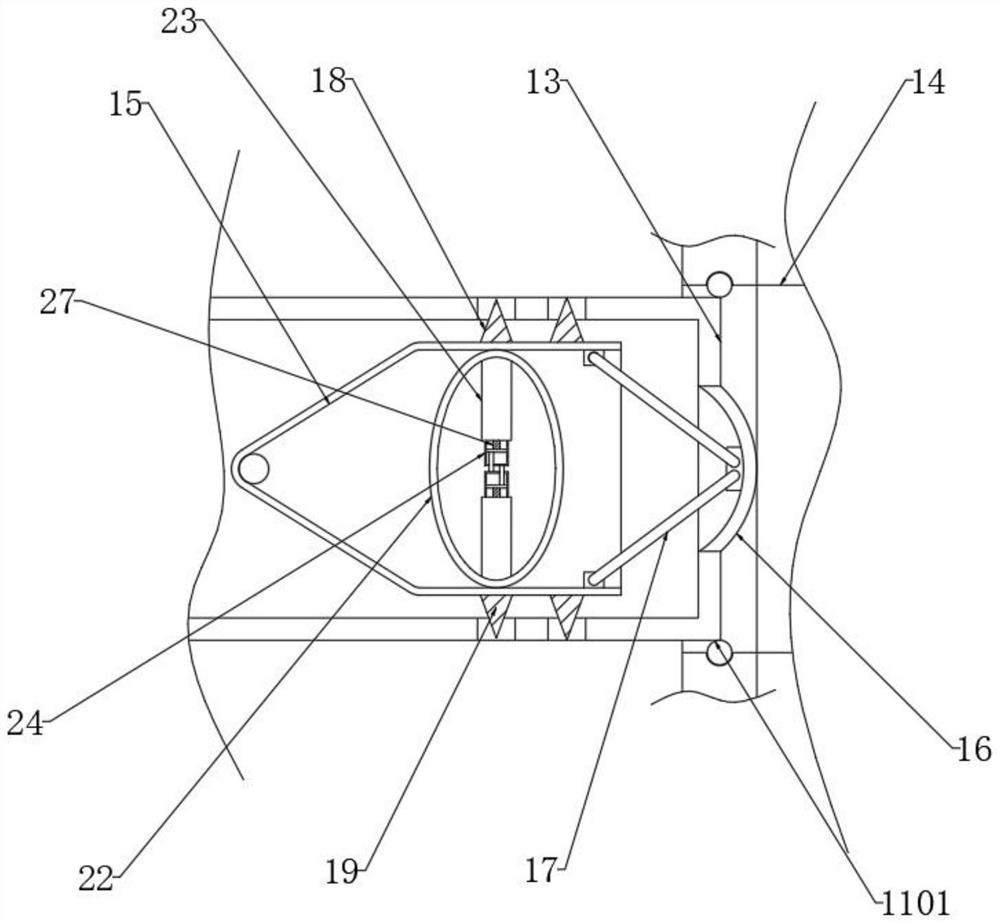

[0041] see Figure 1-6 , a sub-section joint structure of a prefabricated underground diaphragm wall, comprising a removable steel plate 1, the outer end of the removable steel plate 1 is installed with a pre-formed steel plate 2, and the inner wall of the pre-formed steel plate 2 is fixedly connected with two upper and lower symmetrical limit stop frames 5. The outer end of the preformed steel plate 2 is installed with a horizontal steel bar 6, the outer end of the horizontal steel bar 6 is fixedly connected with a longitudinal steel bar 7, the outer end of the horizontal steel bar 6 is installed with a rubber water stop 4, and the outer end of the preformed steel plate 2 is installed There is a shaft sleeve and pin kit 3, and the limit stop frame 5 is fixedly connected with two up and down symmetrical liquid storage balls 8. The liquid storage ball 8 is filled with carbon dioxide aqueous solution, and the inner wall of the limit stop frame 5 is fixedly connected with a straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com