Foundation bolt pre-embedding positioning device and construction method thereof

A technology of anchor bolts and positioning devices, which is applied in the direction of construction, building construction, and building materials processing, can solve problems such as difficult work, inability to guarantee the verticality of anchor bolts, and unreliable fixing methods of anchor bolts. Achieve the effect of good overall stability, overcome the difficulty of overall mold taking, and facilitate mold taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

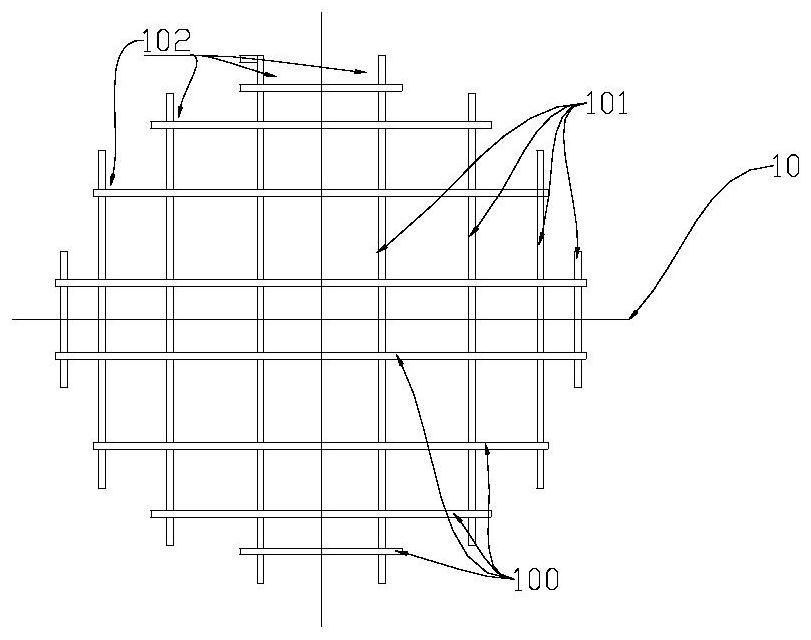

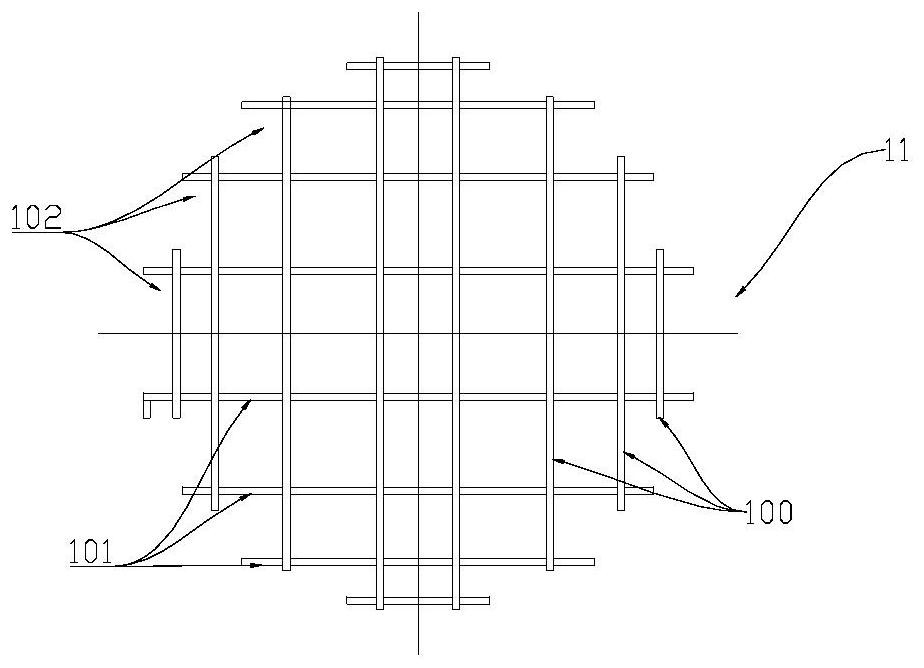

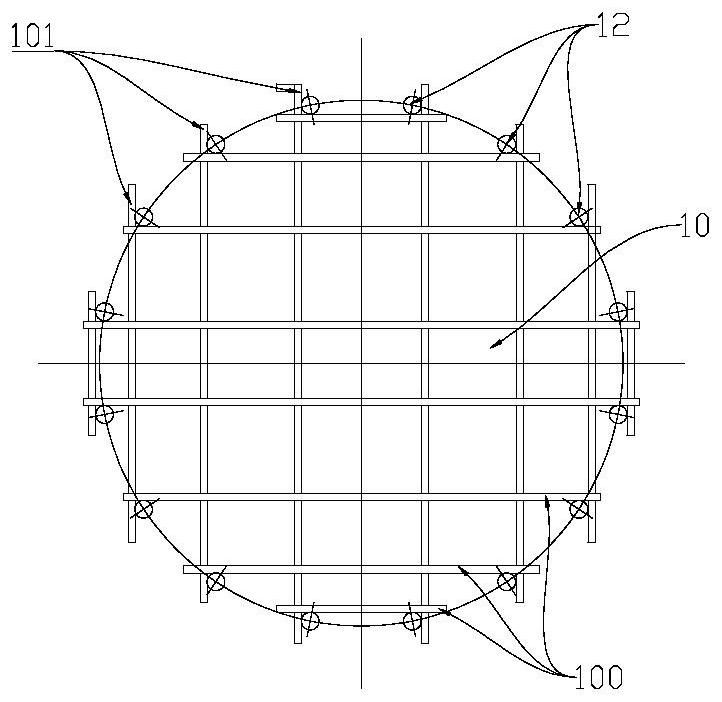

[0045] This embodiment provides a pre-embedded positioning device for anchor bolts. The pre-embedded positioning device for anchor bolts provided by this embodiment is suitable for the case where there is no vertical rib in the center of the anchor bolt group. as 1 to Figure 13 As shown, the anchor bolt embedded positioning device of the present invention includes a first positioning bracket 10 and a second positioning bracket 11, and the anchor bolt embedded positioning device of the present embodiment is composed of the first positioning bracket 10 and the second positioning bracket 11 are stacked up and down in a cross to position each anchor bolt 12 in four directions.

[0046] Preferably, the first positioning bracket 10 and the second positioning bracket 11 are well-shaped frames formed by at least two longitudinal bars 101 and at least two transverse bars 100 intersecting each other, wherein the ends of the longitudinal bars 101 protrude beyond the intersection of the ...

Embodiment 2

[0058] Embodiment 2 provides another pre-embedded positioning device for anchor bolts. The pre-embedded positioning device for anchor bolts provided in this embodiment is suitable for the case where there is a vertical bar in the center of the anchor bolt group. The difference with embodiment 1 is:

[0059] Such as Figure 14 to Figure 23 As shown, the first positioning bracket 10 and the second positioning bracket 11 also include a relief structure 103, and the relief structure 103 is used to make way for the vertical rib 13, so as to prevent the first positioning bracket 10 and the second positioning bracket 11 from being stuck on the vertical rib 13, so that the first positioning bracket 10 and the second positioning bracket 11 cannot be placed horizontally. Preferably, the relief structure 103 is a notch structure extending longitudinally outward from the center of the positioning bracket. When in use, make the relief structure 103 vertically put into the middle of the a...

Embodiment 3

[0063] This embodiment provides a construction method applicable to a kind of anchor bolt pre-embedded positioning device described in Embodiment 1 (in the case of no vertical reinforcement in the center of the anchor bolt group), including the following steps:

[0064] Step 1: Laying the bottom reinforcement bar 23 of the tower crane foundation; Figure 24 with Figure 25 shown.

[0065] Preferably, when there is no vertical rib in the center of the anchor bolt group, the structure of the support frame 22 is as follows: Figure 26 with Figure 27 as shown, Figure 26 with Figure 27 A schematic structural view of a supporting frame 22 in a preferred embodiment is shown. Preferably, the supporting frame 22 is arranged above the steel bar 23 at the foundation floor. The support frame 22 includes four-corner vertical ribs 220, oblique vertical ribs 222 and support crosspieces 221, and in this embodiment, the top positions of the four-corner vertical ribs 220 are flush with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com