Plugging device for municipal pipeline port

A technology for plugging devices and municipal pipelines, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of inconvenient installation and disassembly, time-consuming, energy-consuming, unstable, etc., and achieve a stable plugging effect. Easy and efficient installation, stable adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

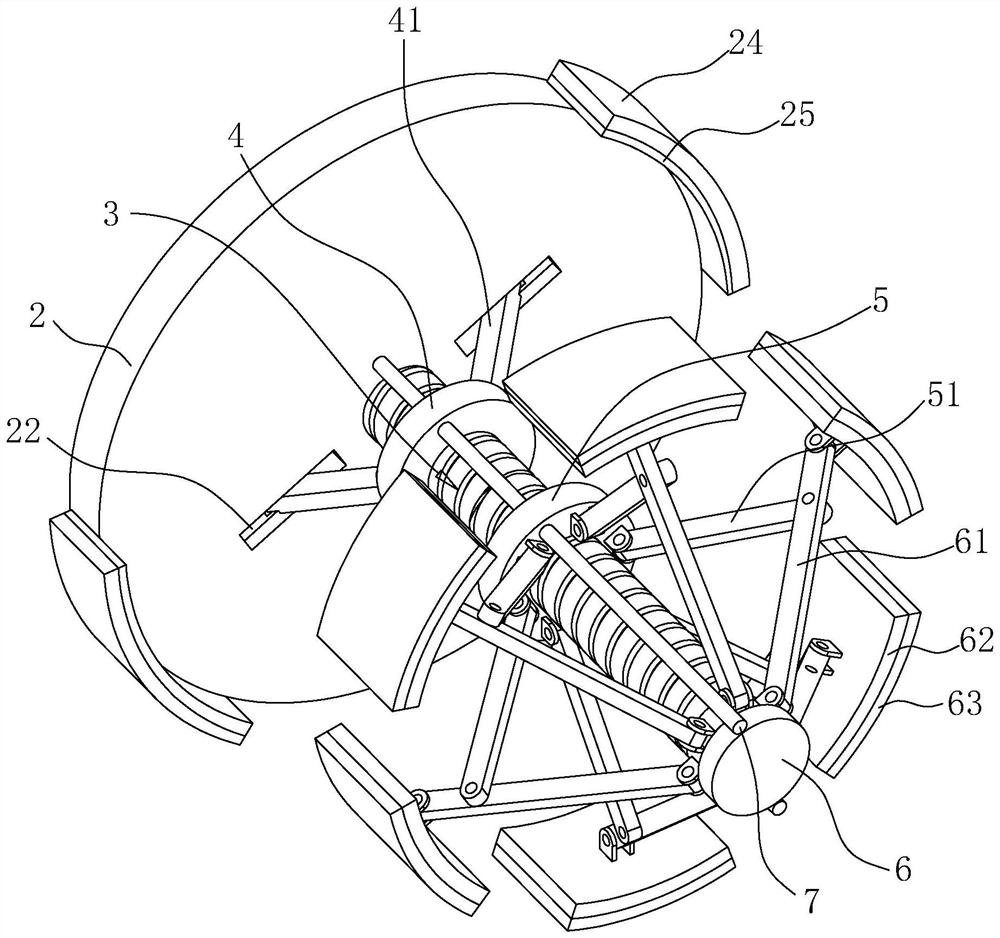

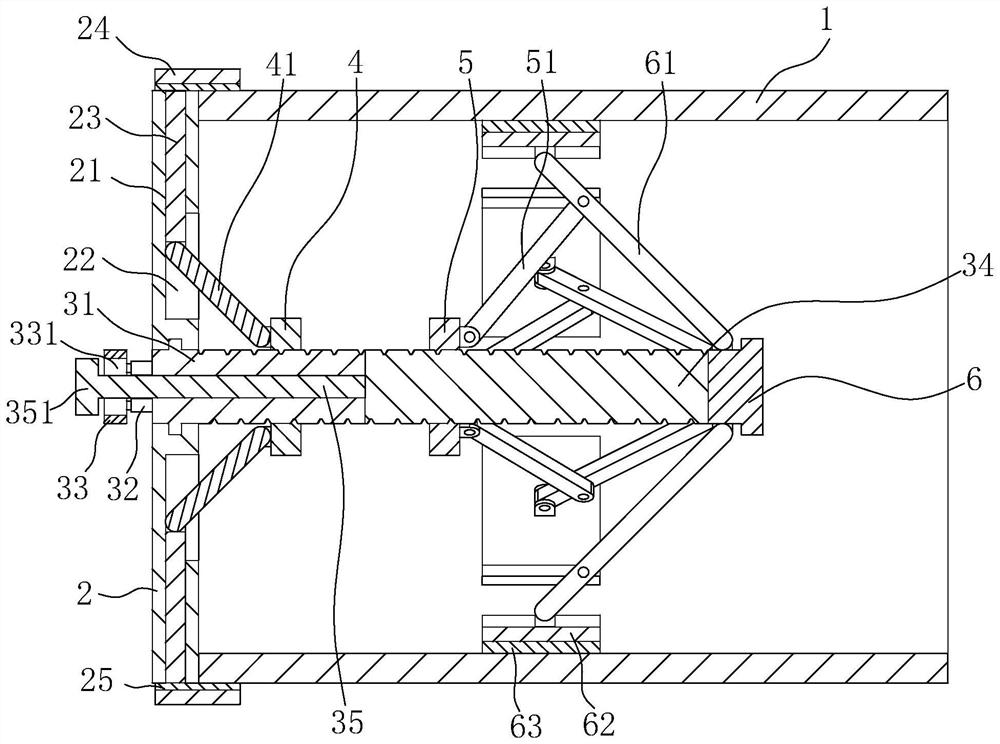

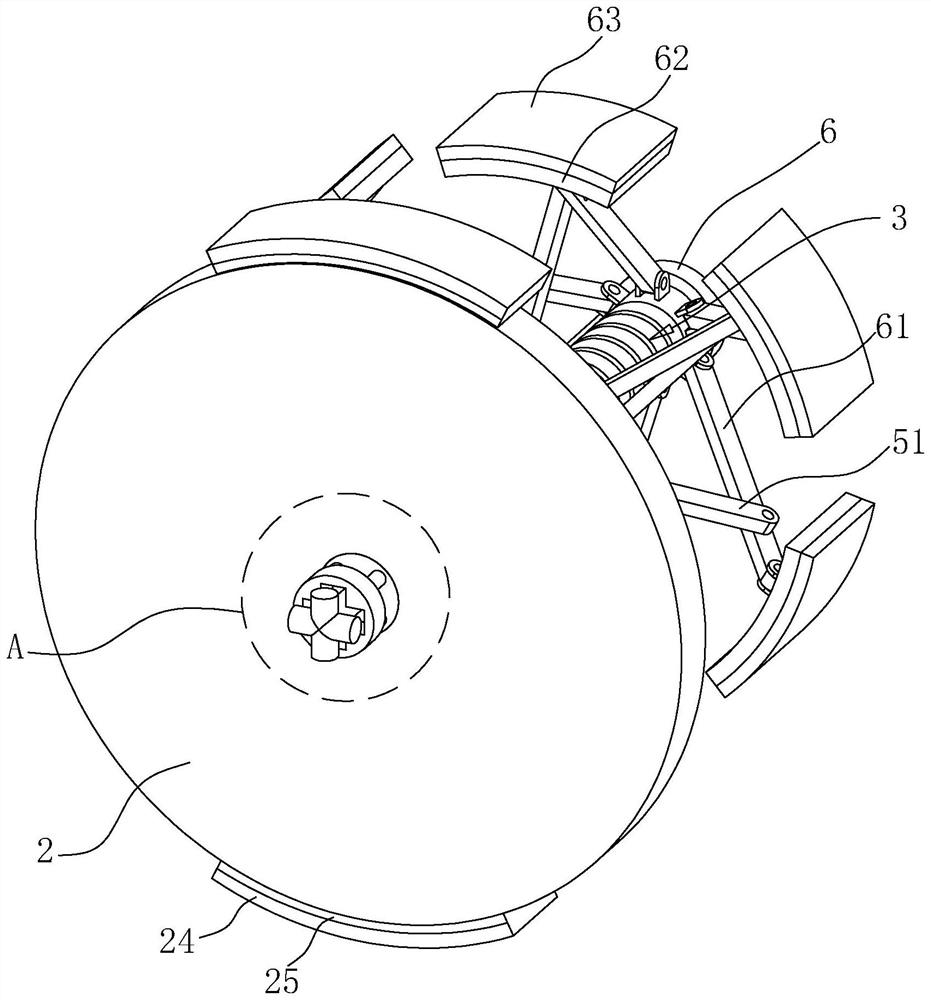

[0037] The following is attached Figure 1-4 The application is described in further detail.

[0038] The embodiment of the present application discloses a plugging device for a municipal pipeline port. refer to figure 1 and figure 2 , the plugging device includes an outer end cover 2 and a screw rod 3, the outer end cover 2 is a circular flat plate, and the outer end cover 2 is in close contact with the nozzle of the pipeline 1; the outer end cover is provided with a clamp for clamping the outer wall of the pipeline 1 Tightening mechanism; the screw rod 3 is perpendicular to the outer end cover 2, one end of the screw rod 3 is rotationally connected with the middle part of the outer end cover 2, and the other end extends into the interior of the pipeline 1 along the horizontal direction, and the screw rod 3 is provided with a plurality of holes for pressing against the inner wall of the pipeline 1 block 62.

[0039] refer to figure 2 and image 3 , the screw 3 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com