Defective product removing equipment for fry rearing

A technology for defective products and fry, applied in application, fish farming, climate change adaptation, etc., can solve the problems of labor consumption and low efficiency, and achieve the effect of ensuring water quality, reducing damage rate, and simplifying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

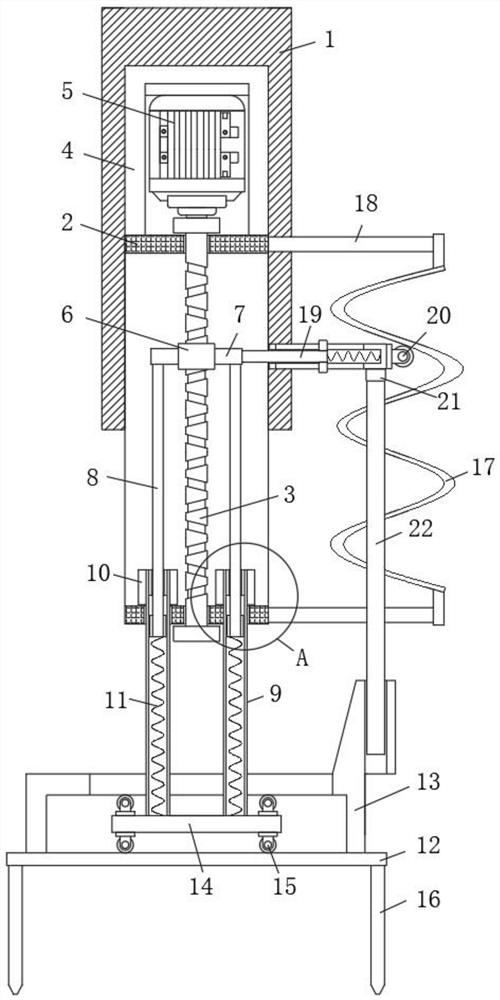

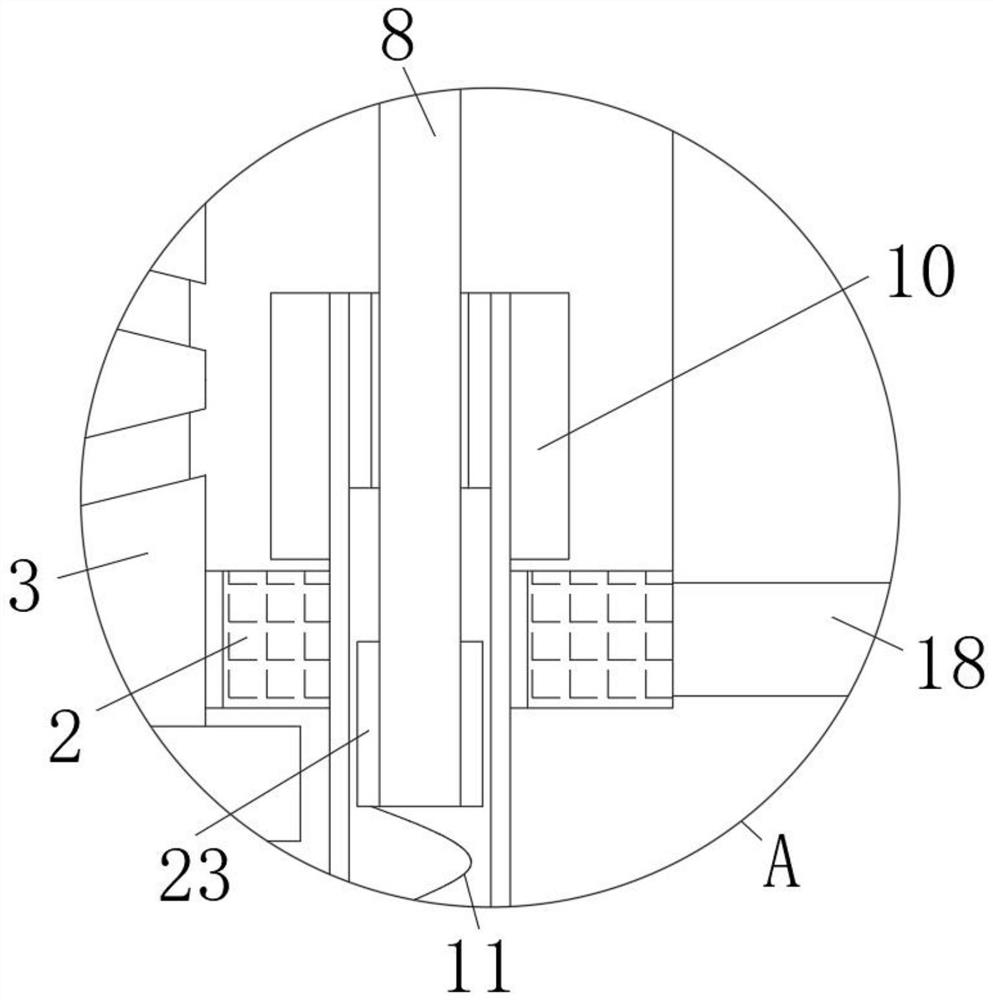

[0027] refer to Figure 1-4 , a kind of equipment for removing defective products for fish fry cultivation, including a sliding hanger 1. In the process of modern cultivation, pneumatic or electric walking tracks will be laid on the top or one side of the water area, and the sliding hanger 1 is installed on the walking track. , so that the entire equipment can be moved to the vertical top of the fish nest, the bottom of the sliding hanger 1 is fixedly hoisted with a rectangular mounting frame 2, and the vertical rotation of the rectangular mounting frame 2 is installed with a reciprocating screw 3, and the top of the rectangular mounting frame 2 A motor mounting frame 4 is fixed, and a servo motor 5 is fixedly installed by bolts in the motor mounting frame 4. The output shaft of the servo motor 5 is fixed to one end of the reciprocating lead screw 3, and the outer side of the reciprocating lead screw 3 is equipped with a lead screw nut 6. The vertical lower part of the rectang...

Embodiment 2

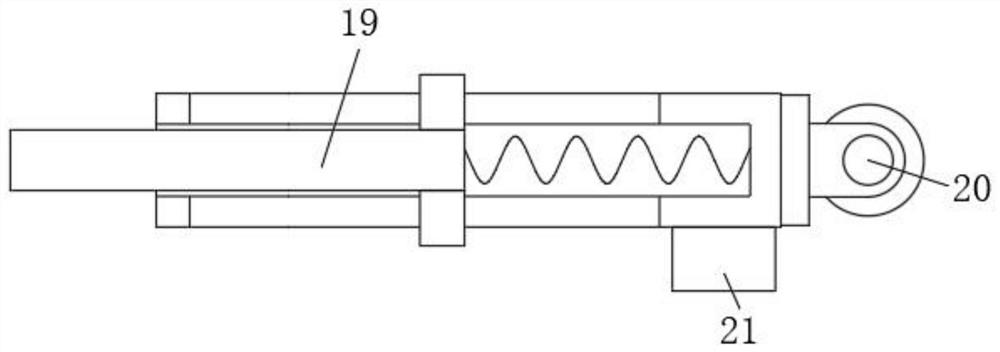

[0032] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are four fixed rods 18 and they are respectively located at the four corners of the rocking S-shaped track plate 17, one side of the contact roller 20 and one side of the rocking S-shaped track plate 17. Sliding contact connection.

[0033] In this embodiment, the arrangement of the contact rollers 20 reduces friction and ensures the operation of the equipment.

Embodiment 3

[0035] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the horizontal plate 21 is located at the bottom of one end of the elastic telescopic rod 19 close to the contact roller 20 .

[0036] In this embodiment, the horizontal plate 21 can move horizontally during the stretching process of the elastic telescopic rod 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com