Waterproof coiled material production process

A technology of waterproof roll material and production process, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., and can solve problems such as expensive, dangerous, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

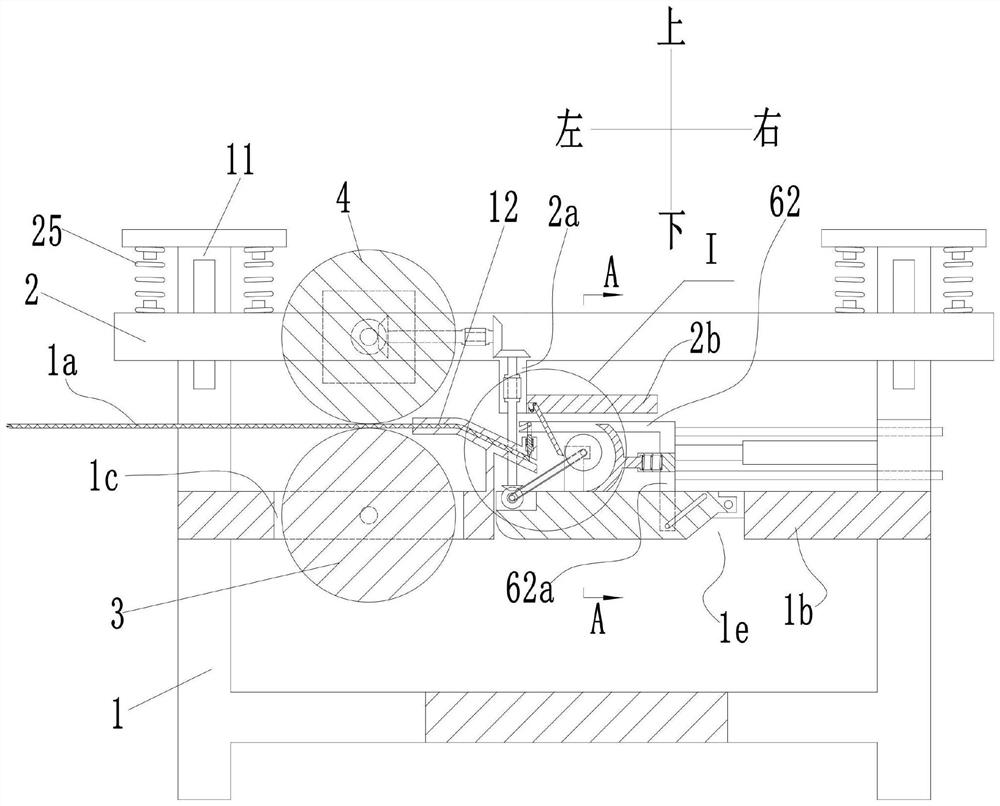

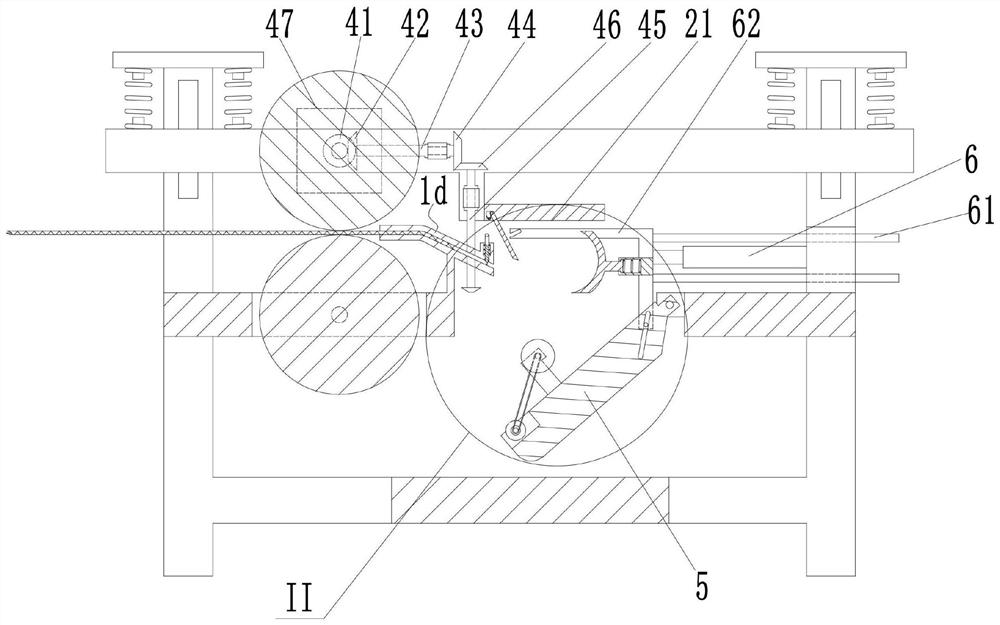

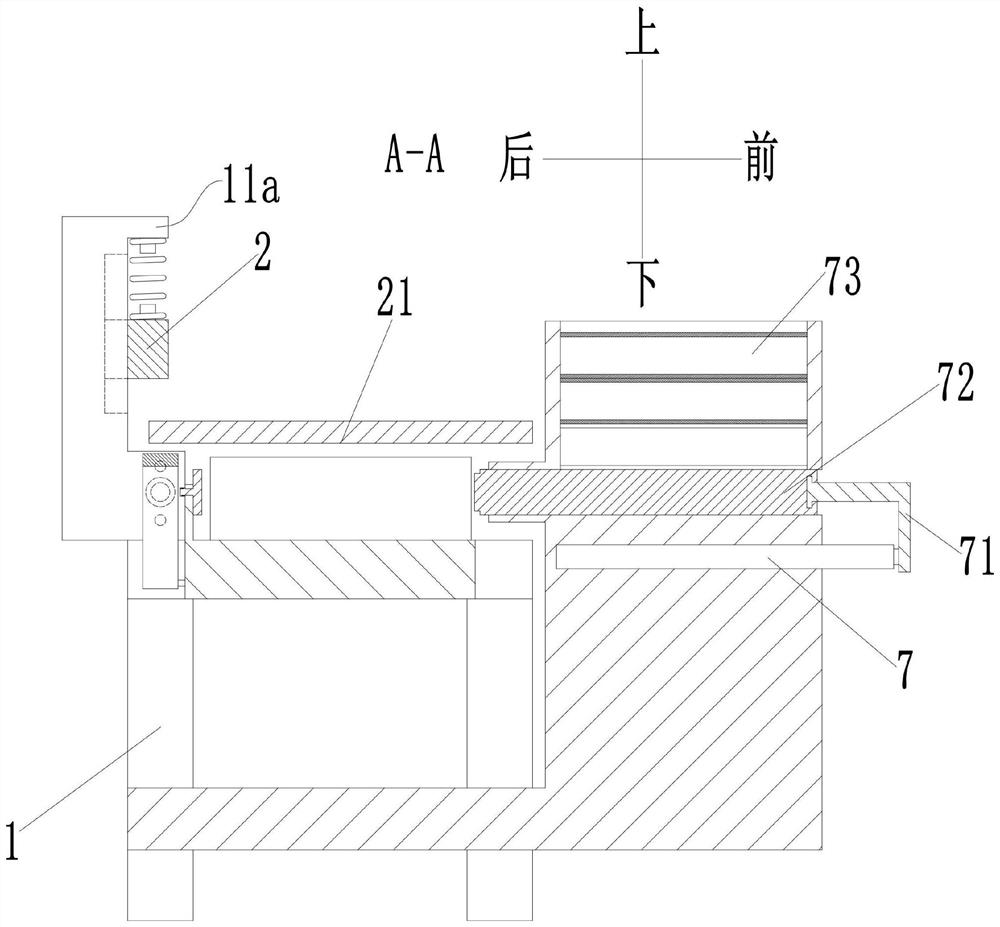

[0032] see Figure 1-7 As shown, a waterproof coiled material production process, the waterproof coiled material production process uses a retracting device, the retracted device includes a frame 1, and the frame 1 is provided with a coiled material introduction component and a roll installation component , a reel drive assembly, a reel blanking assembly, a transmission assembly is provided between the introduction assembly and the reel drive assembly; the waterproof membrane production process includes the following steps:

[0033] S1. Send the produced waterproof membrane from the left end of the frame 1 into the introduction assembly, so that the waterproof membrane 1a enters the working position;

[0034] S2. Control the reel installation assembly to install the reel 73 in the reel drive assembly, so that the reel 73 is in the winding position;

[0035]S3. Control the work of the importing assembly. The importing assembly drives the reel driving assembly to work through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com