Self-lubricating extrusion die material for aluminum profile machining and method for manufacturing extrusion die

A technology for processing aluminum profiles and extruding molds, which is applied in the field of mold manufacturing, can solve the problems of cavity wear, extrusion mold cavity out-of-tolerance time, high production costs, etc., to reduce friction and wear, and avoid surface nitriding process , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

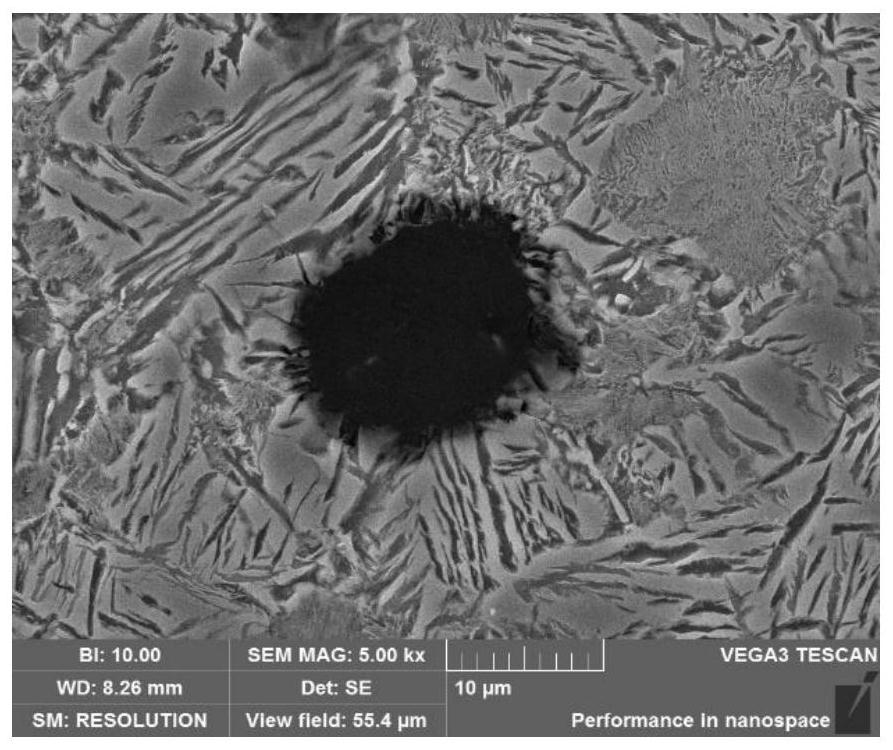

Image

Examples

Embodiment 1

[0040] The present invention also provides a method for manufacturing an extrusion die using a self-lubricating extrusion die material for aluminum profile processing, specifically implemented according to the following steps:

[0041] Step 1, weigh the following components according to mass percentage: C 4.0%, Si 2.2%, Mn 1.3%, Ni 2.0%, Cu 1.5%, Mg0.03%, P0.03%, S0.03%, the balance is Fe, the sum of the mass percentages of the above components is 100%;

[0042] Step 2, smelting the material weighed in step 1 in a high-temperature melting furnace with a temperature of 1520°C until it is completely melted to obtain mixed molten iron;

[0043] Step 3, pouring the mixed molten iron obtained in step 2 into the preheated continuous casting machine matching holding furnace through the transfer ladle for heat preservation, adding ferrosilicon nodulizer and rare earth inoculant for spheroidization and inoculation, to obtain the production of molten iron;

[0044] Among them, the prehea...

Embodiment 2

[0053] The present invention also provides a method for manufacturing an extrusion die using a self-lubricating extrusion die material for aluminum profile processing, specifically implemented according to the following steps:

[0054] Step 1, weigh the following components according to mass percentage: C 2.5%, Si 3.2%, Mn 0.3%, Ni 1.0%, Cu 0.5%, Mg 0.01%, P 0.01%, S0.01%, the balance is Fe, The sum of the mass percentages of the above components is 100%;

[0055] Step 2, smelting the material weighed in step 1 in a high-temperature melting furnace with a temperature of 1320°C until it is completely melted to obtain mixed molten iron;

[0056] Step 3, pouring the mixed molten iron obtained in step 2 into the preheated continuous casting machine matching holding furnace through the transfer ladle for heat preservation, adding ferrosilicon nodulizer and rare earth inoculant for spheroidization and inoculation, to obtain the production of molten iron;

[0057] Among them, the pr...

Embodiment 3

[0063] The present invention also provides a method for manufacturing an extrusion die using a self-lubricating extrusion die material for aluminum profile processing, specifically implemented according to the following steps:

[0064] Step 1, weigh the following components according to mass percentage: C 3.3%, Si 2.8%, Mn 1.8%, Ni1.5%, Cu1%, Mg0.02%, P0.02%, S0.02%, and the balance is Fe, the sum of the mass percentages of the above components is 100%;

[0065] Step 2, smelting the material weighed in step 1 in a high-temperature melting furnace with a temperature of 1400° C. until it is completely melted to obtain mixed molten iron;

[0066] Step 3, pouring the mixed molten iron obtained in step 2 into the preheated continuous casting machine matching holding furnace through the transfer ladle for heat preservation, adding ferrosilicon nodulizer and rare earth inoculant for spheroidization and inoculation, to obtain the production of molten iron;

[0067] Among them, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com