Road roller for positive texture forming of asphalt pavement

A technology of asphalt pavement and road roller, which is applied in the field of road roller manufacturing, which can solve the problems of inability to fully guarantee the safety of road transportation, weak anti-skid performance of the road surface, and uncontrollable texture characteristics, so as to reduce adverse effects and prevent asphalt from cooling and sticking , the effect of preventing asphalt from sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

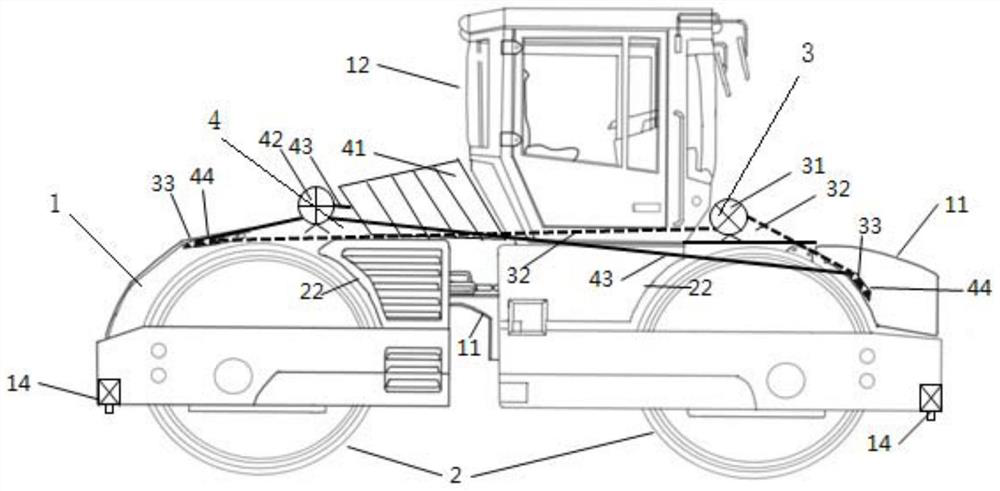

[0025] Specific implementation mode one: refer to Figure 1 to Figure 5 This embodiment is described. This embodiment provides a road roller for positive texture forming of asphalt pavement, the main body frame 1 of the road roller, two steel wheels 2, a high-pressure air injection assembly 3 and a high-pressure liquid injection assembly 4;

[0026] The two steel wheels 2 are respectively mounted on the front and rear ends of the main body frame 1, and each steel wheel 2 is rotationally connected with the main body frame 1, and the high-pressure air injection assembly 3 is installed on the main body frame 1, and the high-pressure air injection assembly 3 The two spray ends of the high-pressure liquid spray assembly 4 are respectively set towards the outer surface of a steel wheel 2, and the high-pressure liquid spray assembly 4 is installed on the main body frame 1, and the two spray ends of the high-pressure liquid spray assembly 4 are respectively facing the outer surface of ...

specific Embodiment approach 2

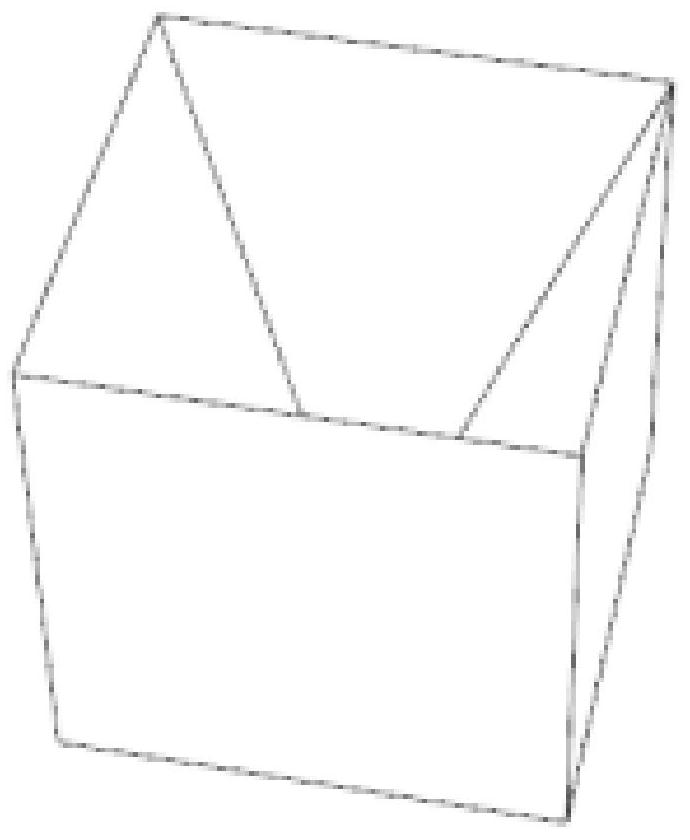

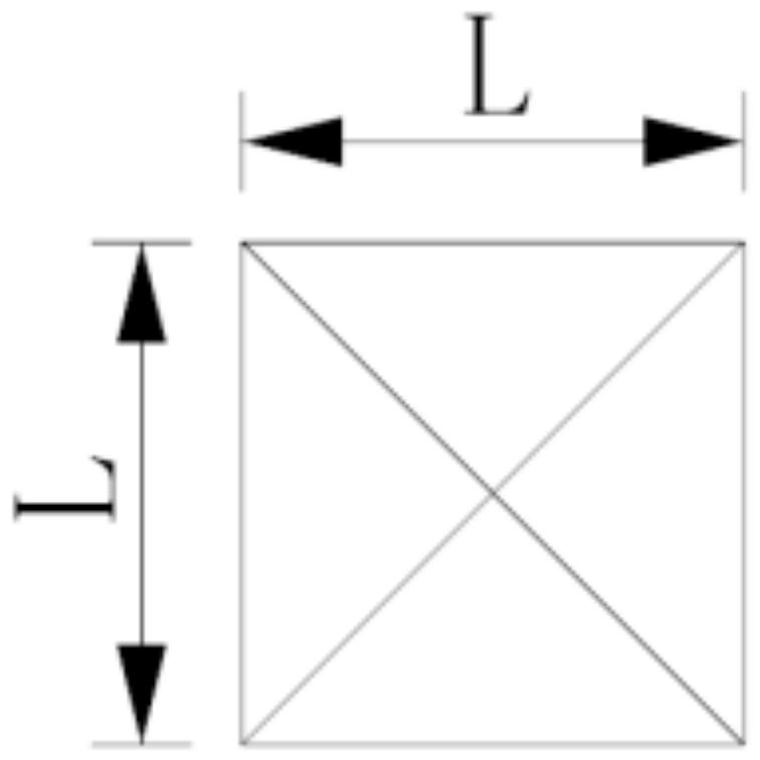

[0030] Specific implementation mode two: refer to Figure 1 to Figure 5 This embodiment is described. This embodiment is to further limit the negative grain steel grain 21 described in the first specific embodiment. Pyramid holes spliced together. Other compositions and connection methods are the same as those in Embodiment 1.

[0031] In this embodiment, the shape of the negative texture monomer is a positive quadrangular pyramid with the tip facing inward, and the side length L and height H of the bottom surface are selected according to the maximum particle size of the asphalt mixture gradation. When the maximum particle size is greater than or equal to 9.5mm, L is 2.36mm and H is 4.75mm; when the maximum particle size is less than or equal to 9.5mm, the texture of L is 1.18mm and H is 2.36mm is selected. This design can be effectively molded on asphalt pavement Reducing the embedding of aggregates while positively textured.

specific Embodiment approach 3

[0032] Specific implementation mode three: refer to Figure 1 to Figure 5Describe this embodiment, this embodiment is to further limit the main frame 1 described in the second specific embodiment, in this embodiment, the cockpit 12 is provided on the main frame 1, and the cockpit 12 is located at the main frame 1 at the center of the top, and the cockpit 12 is welded and fixed with the main body frame 1, and the cockpit 12 is provided with a controller. Other compositions and connection methods are the same as those in the second embodiment.

[0033] In this embodiment, the cockpit 12 can be used by the driver when working. In the cockpit 12, except the existing console for driving the road roller to and fro, a controller is also provided. 3 is connected to the start-stop end of the high-pressure liquid injection assembly 4, so that the driver can control the working status of the heating assembly 22, the high-pressure air injection assembly 3 and the high-pressure liquid inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com