Assembly type integrated active fireproof protection plate and working method thereof

A working method and assembled technology, applied in fire prevention, fire rescue, building components, etc., can solve the problems of poor durability, loss of fire resistance, and poor comprehensive economic benefits of spray-type fire retardant coatings, and achieve enhanced fire protection reliability, splicing and assembly. The effect of convenience and reduced maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

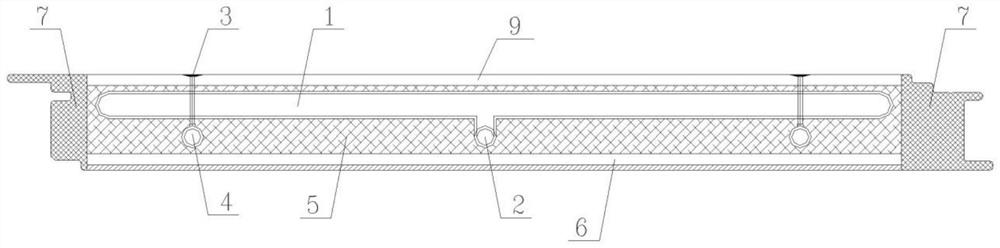

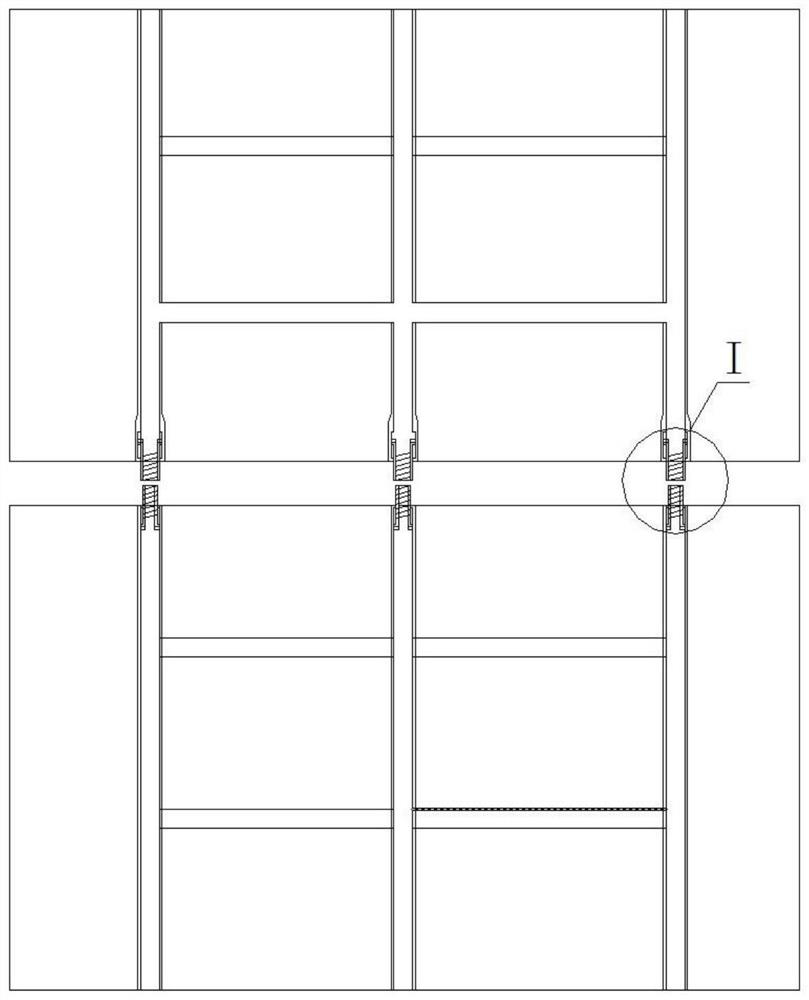

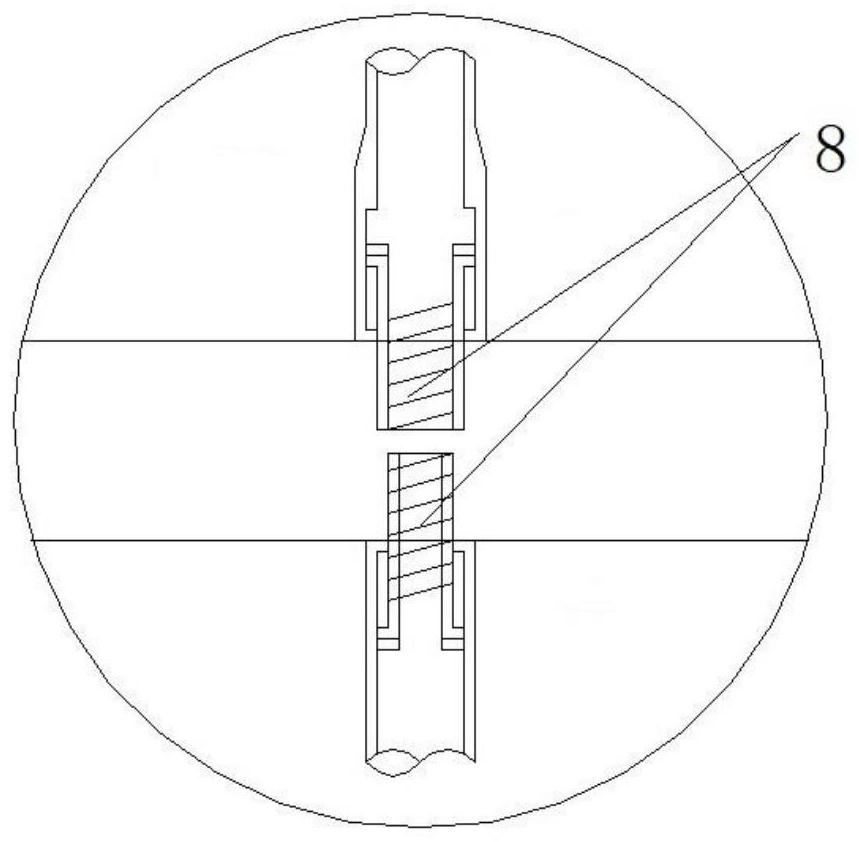

[0028] A prefabricated integrated active fire protection panel, such as Figure 1~3 As shown, it includes water belt heat pipe 2, temperature-sensitive nozzle 3, fire extinguishing water pipe 4, injection molded board 5, fireproof board 1 6, installation socket 7, water pipe active joint 8, fireproof board 2 9, and injection molded board 5 is disposable Formed structure, the first fireproof board 6 is a fireproof board with high thermal conductivity, and the second fireproof board 9 is a hydrophobic fireproof board.

[0029] The inside of the injection molded plate 5 is provided with a plurality of interconnected water belts 1, and the water belts 1 are in the shape of a cross, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com