Parallel storage tank non-isobaric air cushion propellant filling quantity and satellite mass center determination method

A technology for determining methods and propellants, applied in special data processing applications, geometric CAD, aerospace equipment, etc., to reduce calculation time, improve calculation accuracy, and facilitate engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further elaborated below in conjunction with embodiment.

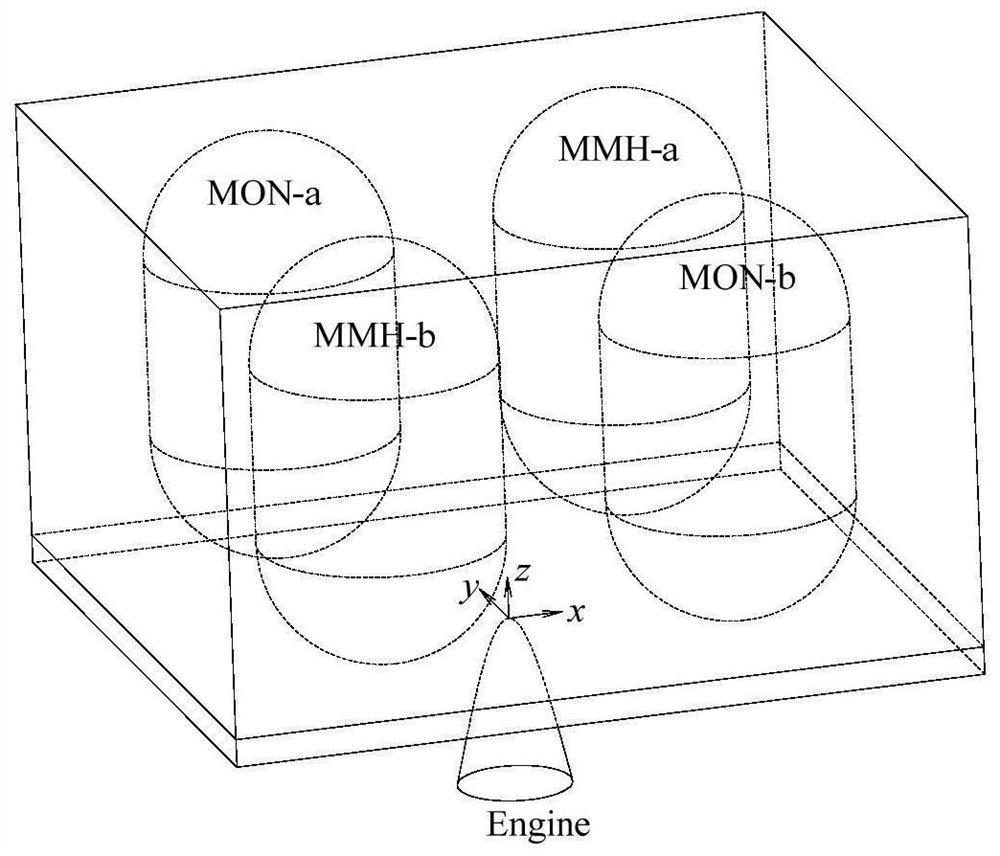

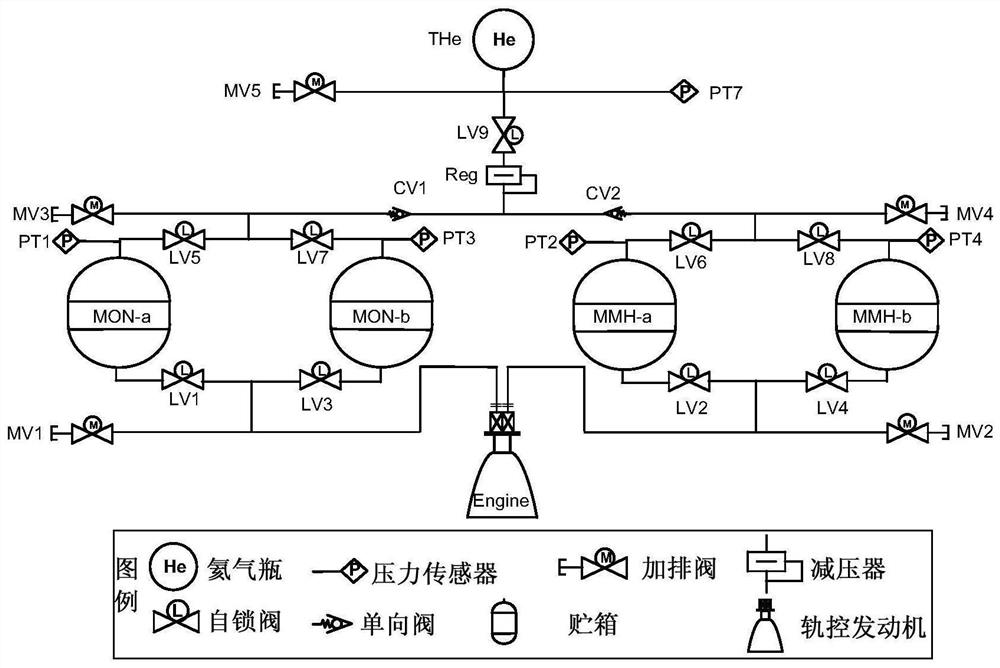

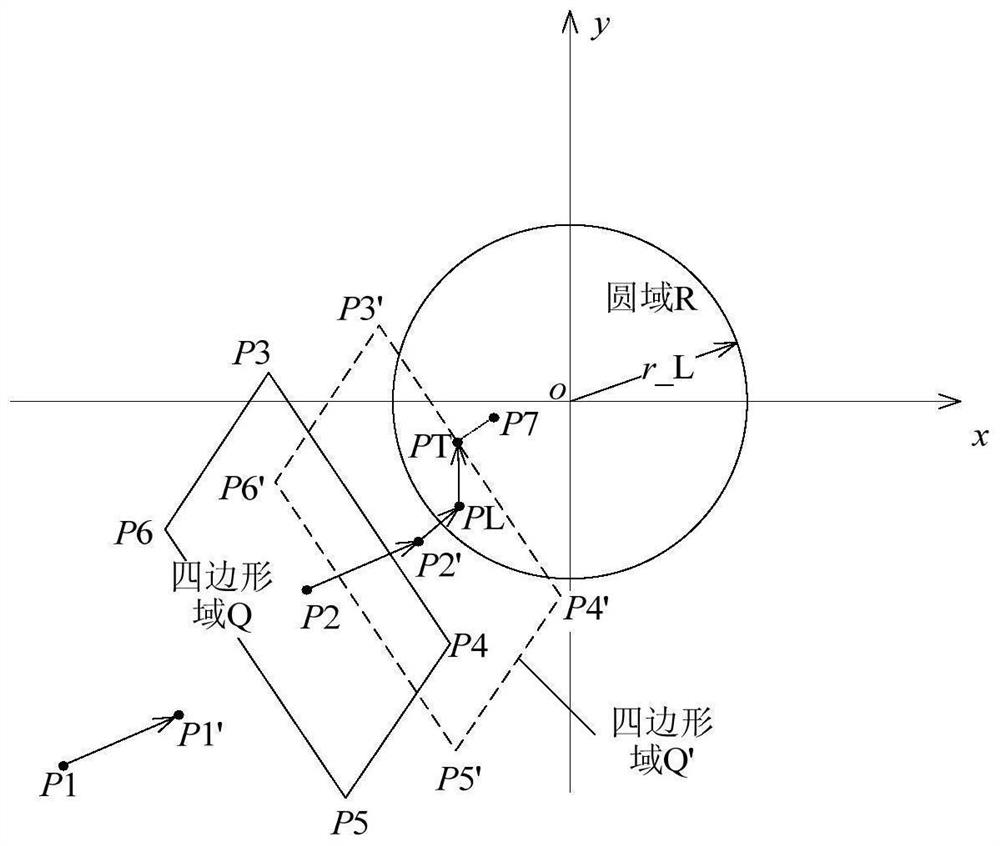

[0081] The filling quantity of non-isobaric air cushion propellant in parallel storage tanks and the determination method of satellite center of mass, such as Figure 1-3 as shown,

[0082] attached figure 1 It is a schematic diagram of parallel storage tank satellite configuration.

[0083] Parallel storage tank satellites generally include 4 storage tanks, including 2 oxygen tanks and 2 fuel tanks, which are oxygen tank a MON-a, oxygen tank b MON-b, fuel tank a MMH-a, fuel tank b MMH- b. The engine Engine is arranged on the base plate of the satellite.

[0084] attached figure 2 It is the schematic diagram of the parallel tank chemical propulsion system, and the name of each single machine is shown in the legend in the figure.

[0085] attached image 3 is the relationship between satellite centroids.

[0086] No counterweight is added: the barycenter of the dry star is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com