Purification device for organic waste gas treatment

A purification device and organic waste gas technology, which is applied in the direction of combined devices, chemical instruments and methods, separation methods, etc., can solve the problems of poor waste gas purification effect, insufficient purification, environmental pollution, etc., and achieve comprehensive and thorough filtration and prevent dust residues Effects of interference and protection from pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

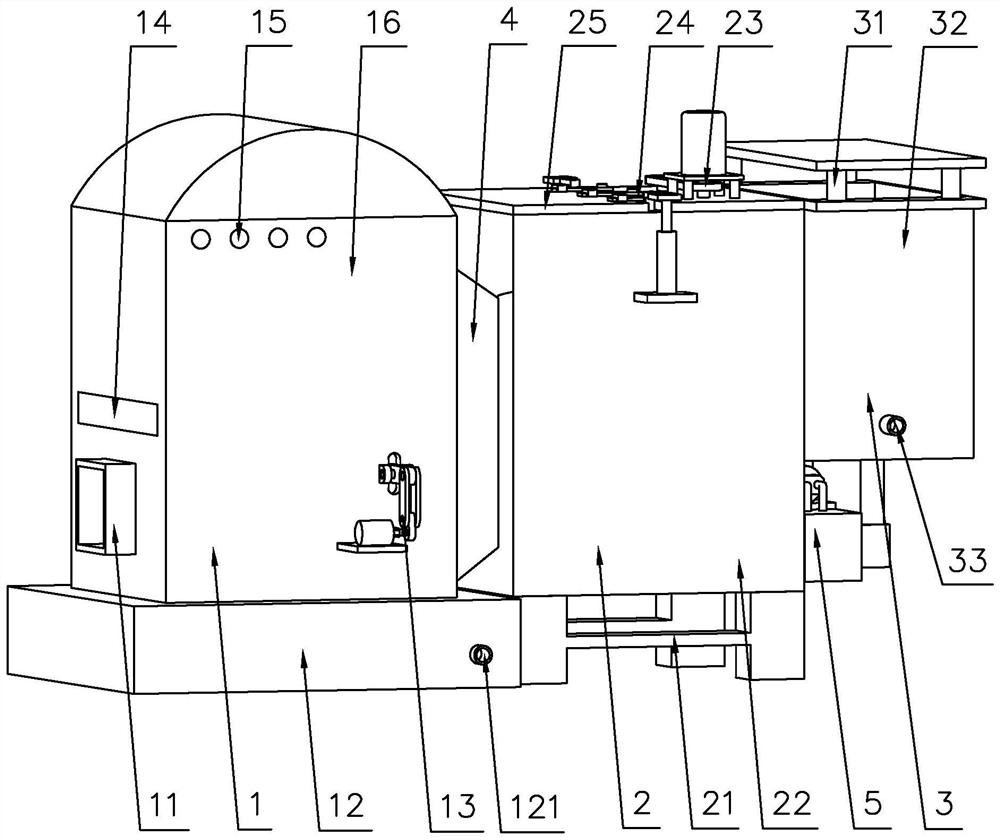

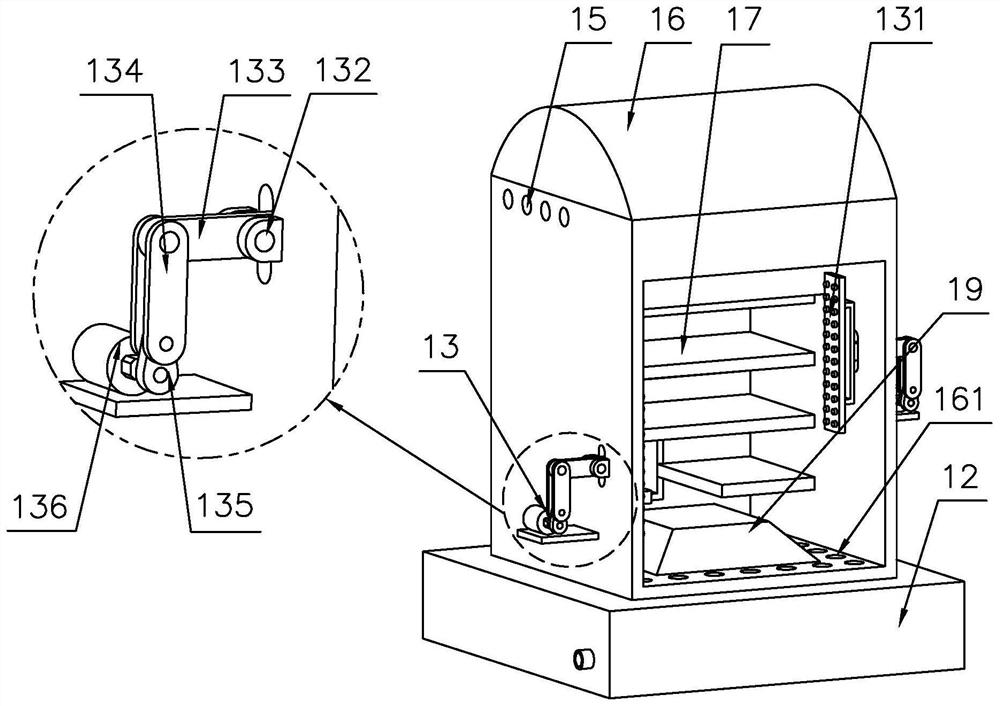

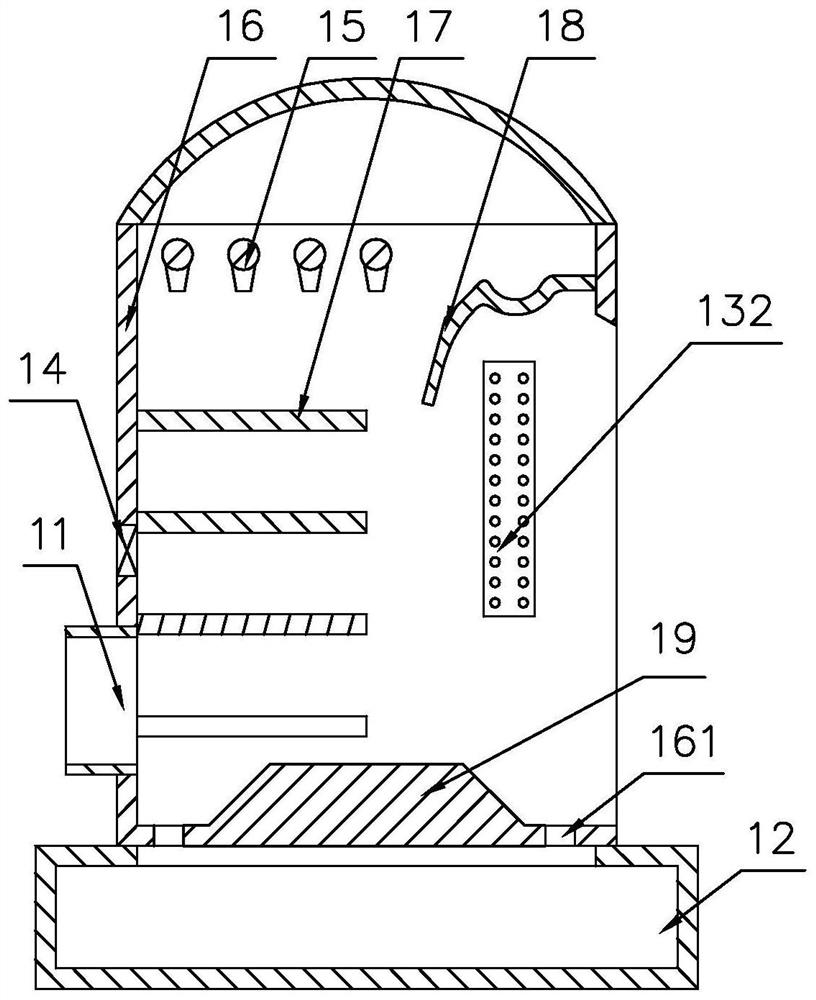

[0032] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-9 , to further specifically describe the technical solution of the present invention.

[0033] A purification device for organic waste gas treatment, comprising a waste gas spray box 1, a purification filter box 2, an adsorption box 3, a ventilation pipe 4, and an exhaust box 5, and a ventilation pipe 4 is provided on one side of the waste gas spray box 1 , one side of the ventilation pipe 4 is provided with a purification filter box 2, one side of the purification filter box 2 is provided with an exhaust box 5, and one side of the exhaust box 5 is provided with an adsorption box 3, between the exhaust gas spray box 1 and the purification filter box 2 It is connected through the ventilation pipe 4, and the inside of the ventilation pipe 4 is equipped with a check valve, so that the exhaust gas can only enter the purification filter box 2 from the exhau...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap