Small powder proportioning device

A powder, small-scale technology, applied in the direction of transportation and packaging, mixer accessories, dissolution, etc., can solve the problems of powder deviation, unqualified quality, errors, etc., and achieve the effect of reducing the proportion error and reducing powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

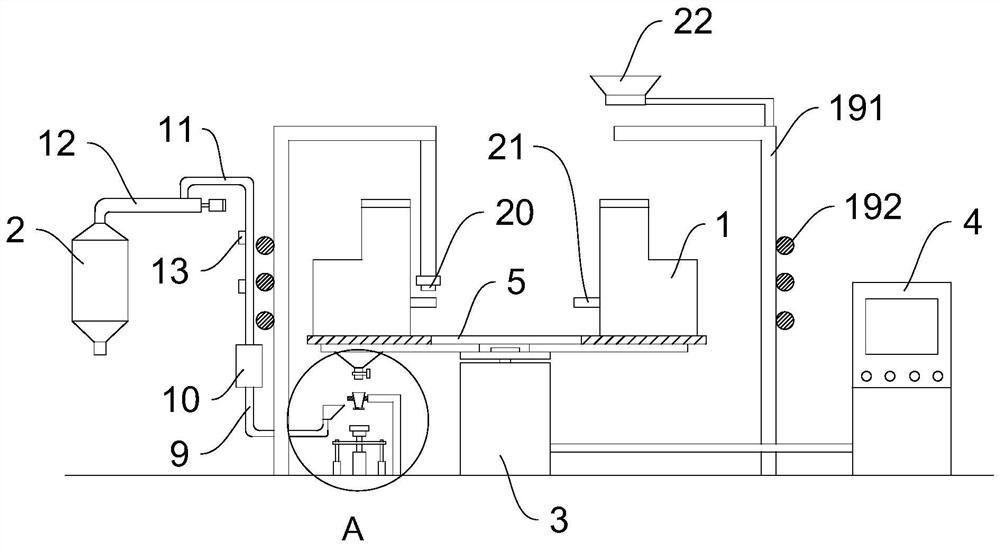

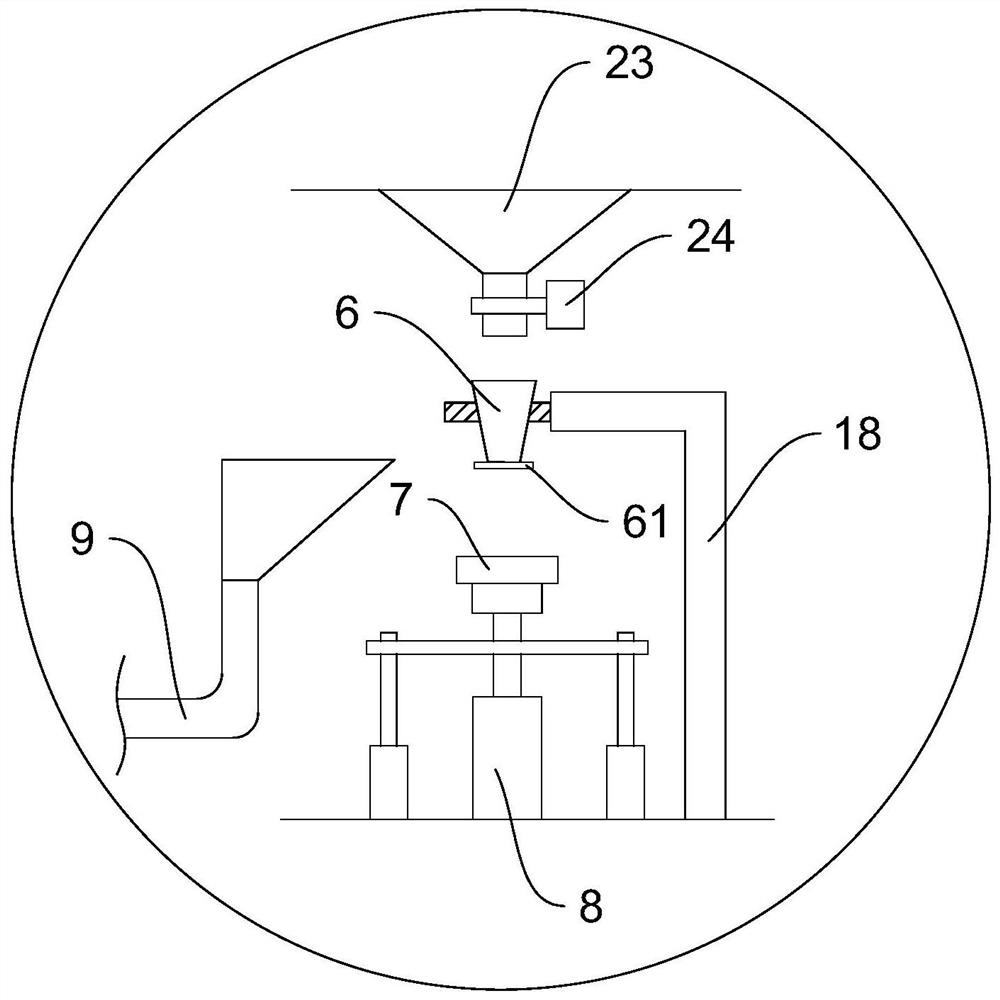

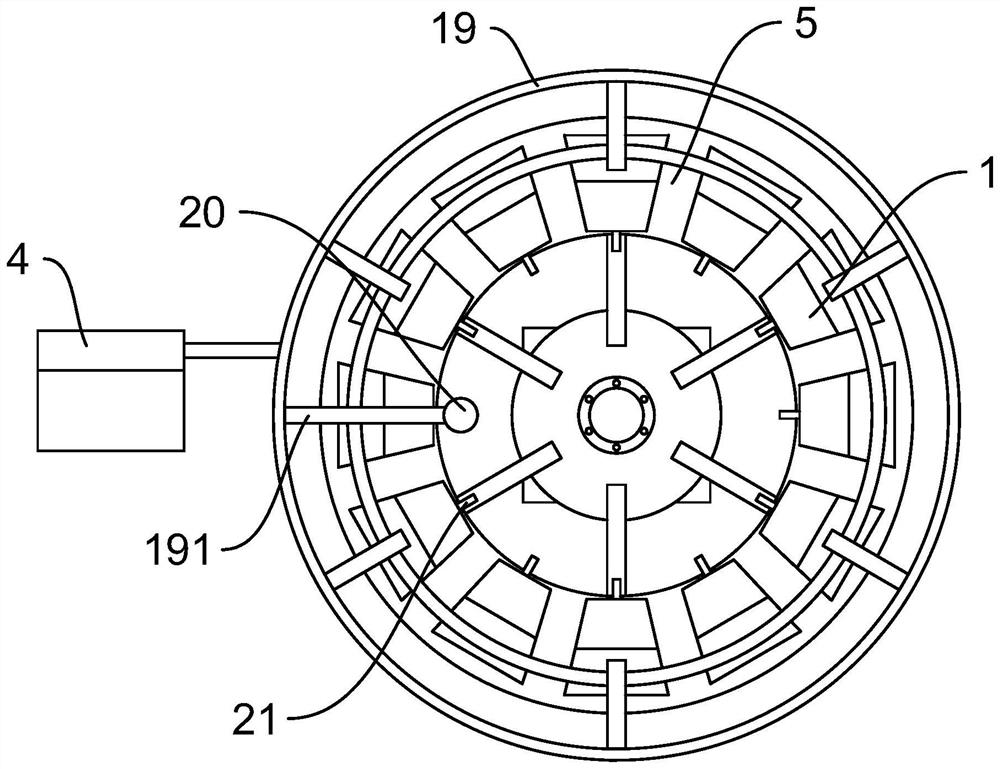

[0026] Further illustrate below in conjunction with specific embodiment, refer to Figure 1-Figure 7 As shown, the present embodiment 1 is a small-scale powder proportioning device, which includes a batching barrel 2 and a plurality of material boxes 1 filled with different powder materials, and also includes a turntable 5, and the material box 1 is evenly spaced and fixed around the turntable 5 circumferential direction , the bottom of the turntable 5 is connected with the main motor 3 to drive, the main motor 3 is electrically connected to the control host 4; the lower end of the material box 1 is provided with a discharge port 23, and the discharge port 23 is equipped with a solenoid valve 24; Connect material barrel 6, when one of the feed boxes 1 was forwarded to the material connection barrel 6 top, the discharge port 23 was aimed at the material connection barrel 6, and the lower end of the material connection barrel 6 was provided with a load cell 7; A suction pipe 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com