An intelligent detection device for bamboo products

A technology of intelligent detection and bamboo products, applied in conveyor control devices, paint spray booths, conveyor objects, etc., can solve the problems of non-recyclability, long curing time, poor working environment, etc., and achieve powder saving and no VOC emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

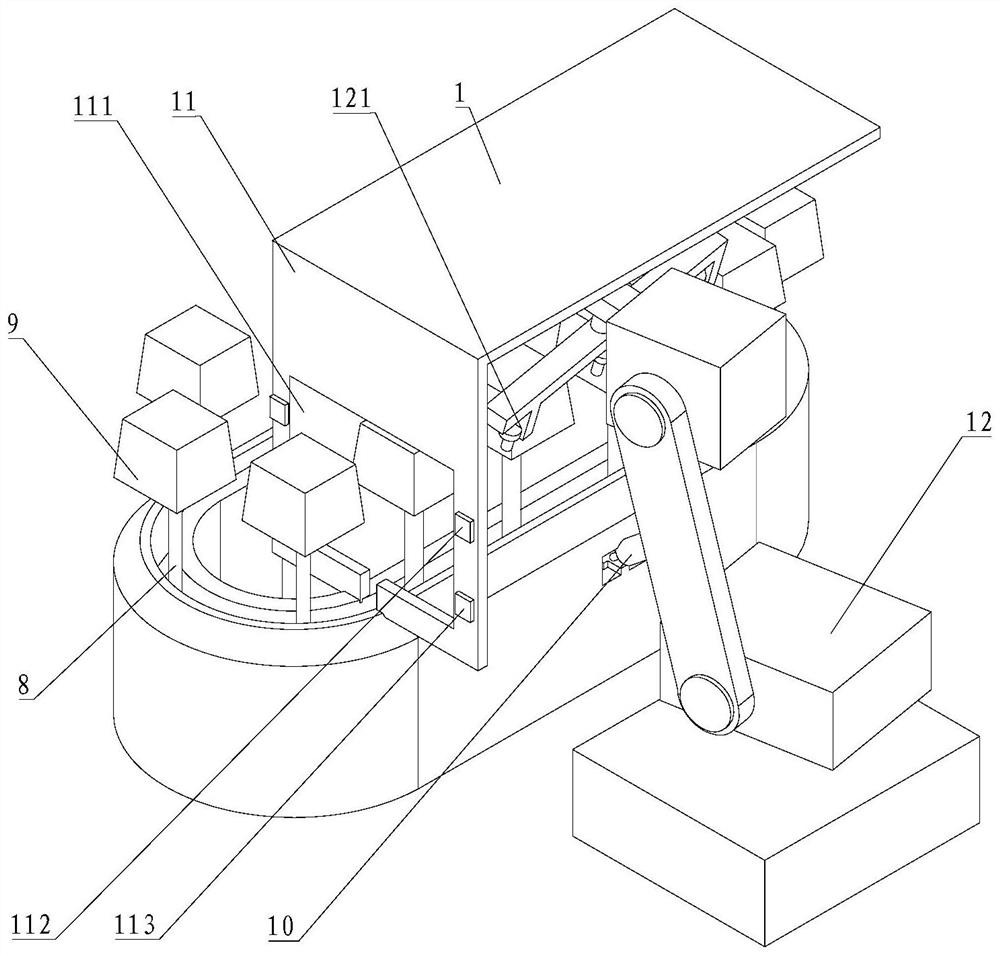

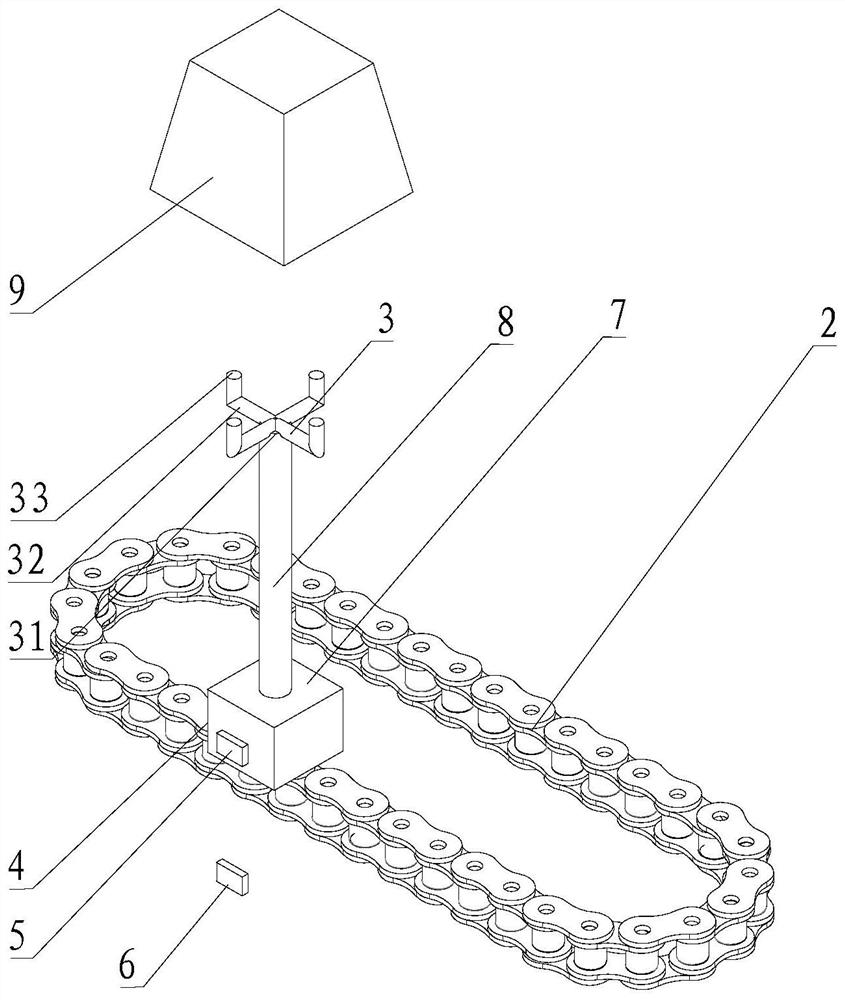

[0053] Please refer to Figure 1 to Figure 2 Shown, embodiment one of the present invention is:

[0054] An intelligent detection device for bamboo products provided by the present invention includes a powder spraying room 1, a conveyor chain 2 and a controller. The powder spraying room 1 includes a side wall 11 and another side wall opposite to the side wall, The one side wall 11 is provided with a feed port 111, and the other side wall is provided with a discharge port, and the conveying chain 2 moves horizontally and passes through the feed port 111 to the discharge port in order to penetrate all The powder spraying room 1, the powder spraying room 1 is located at the position of the feed port and is correspondingly provided with two groups of infrared ray tubes distributed up and down, and the transmission chain 2 is provided with a vertical support frame 3; each group of infrared ray pairs The radiation tube is composed of an infrared emitter and an infrared receiver. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com