A fully automatic powder spraying equipment

A fully automatic, powder spraying technology, applied in spray booths, spray devices, etc., can solve the problems of non-recyclability, low efficiency, poor working environment, etc., to achieve no VOC emissions, improve dust removal effect, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

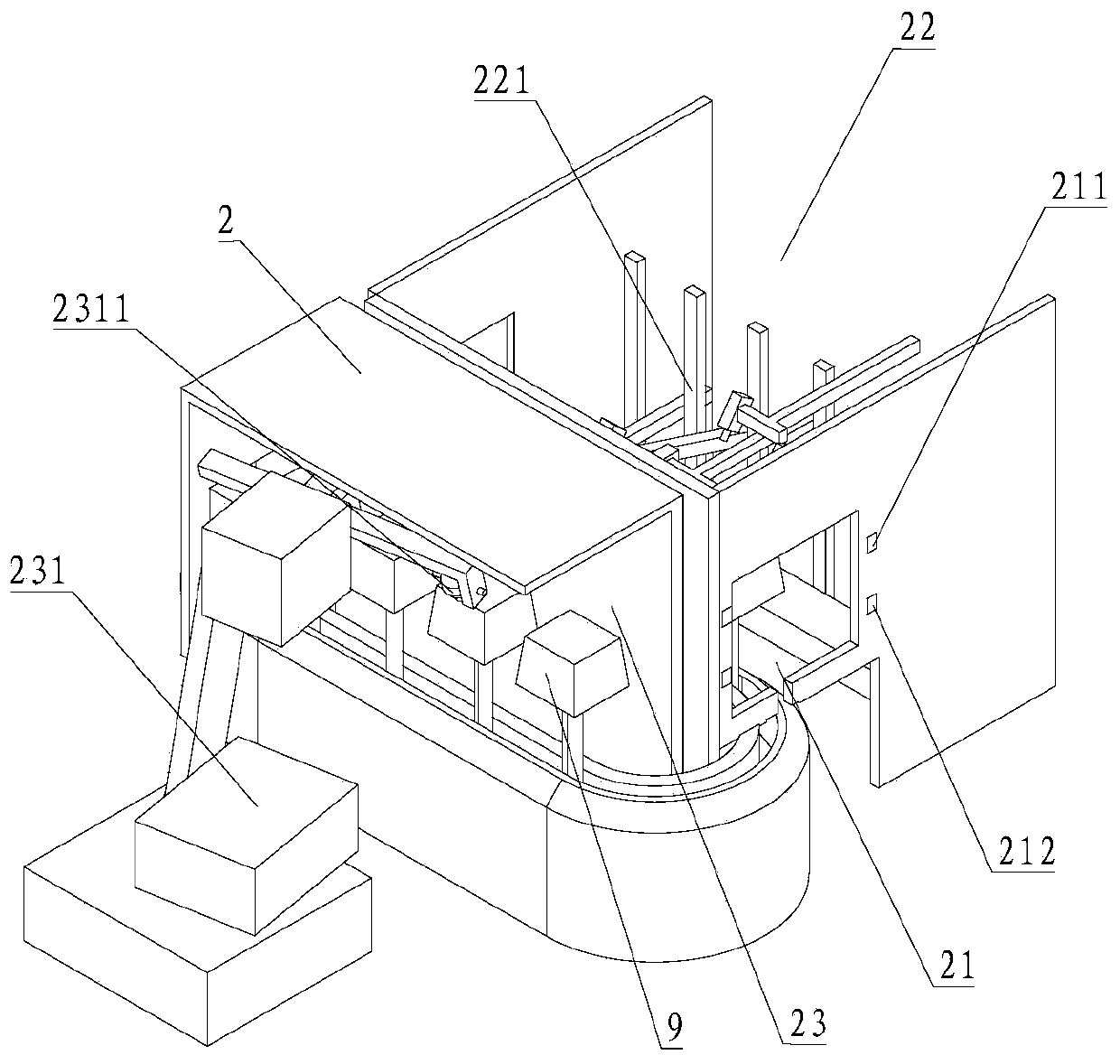

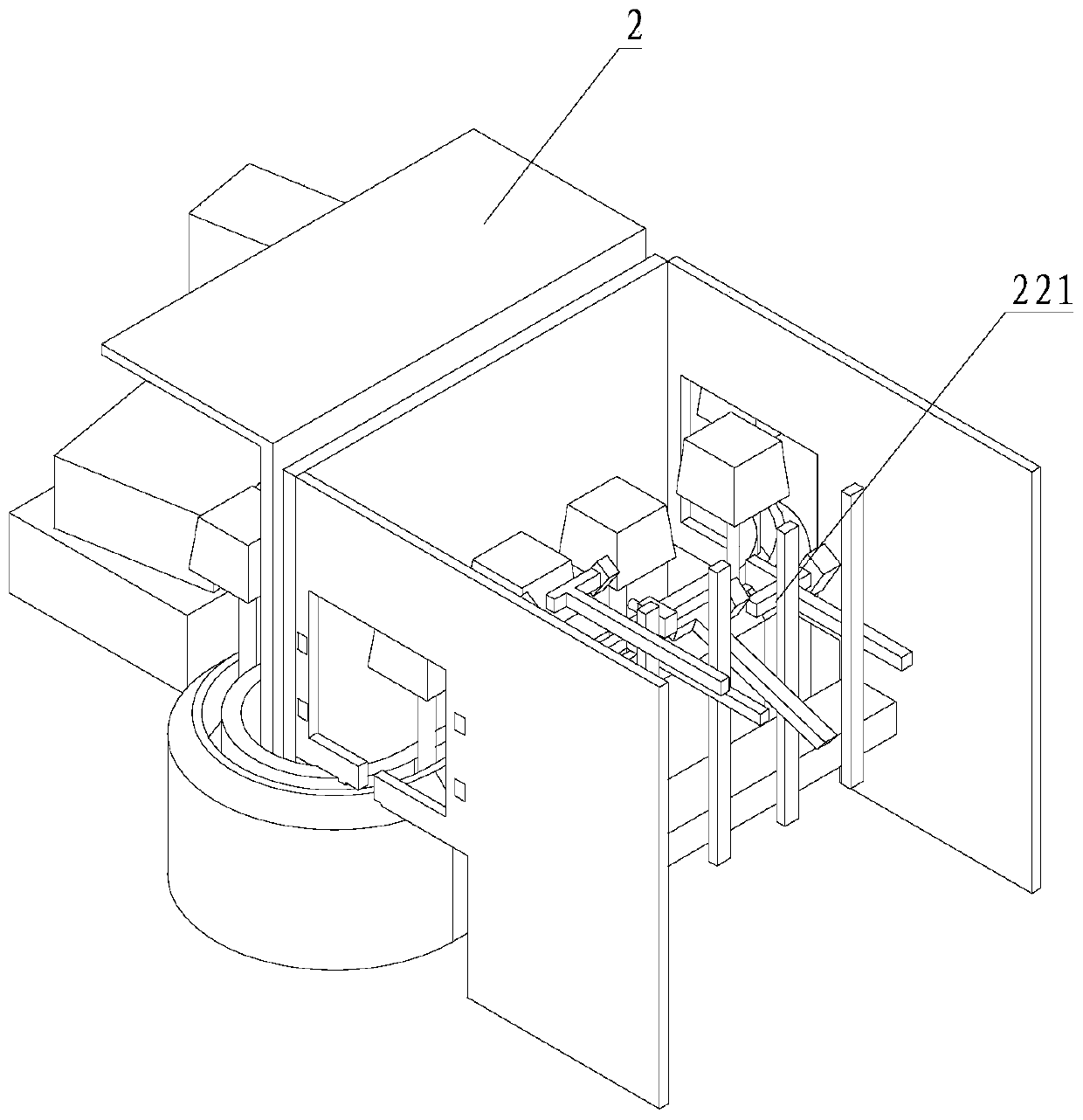

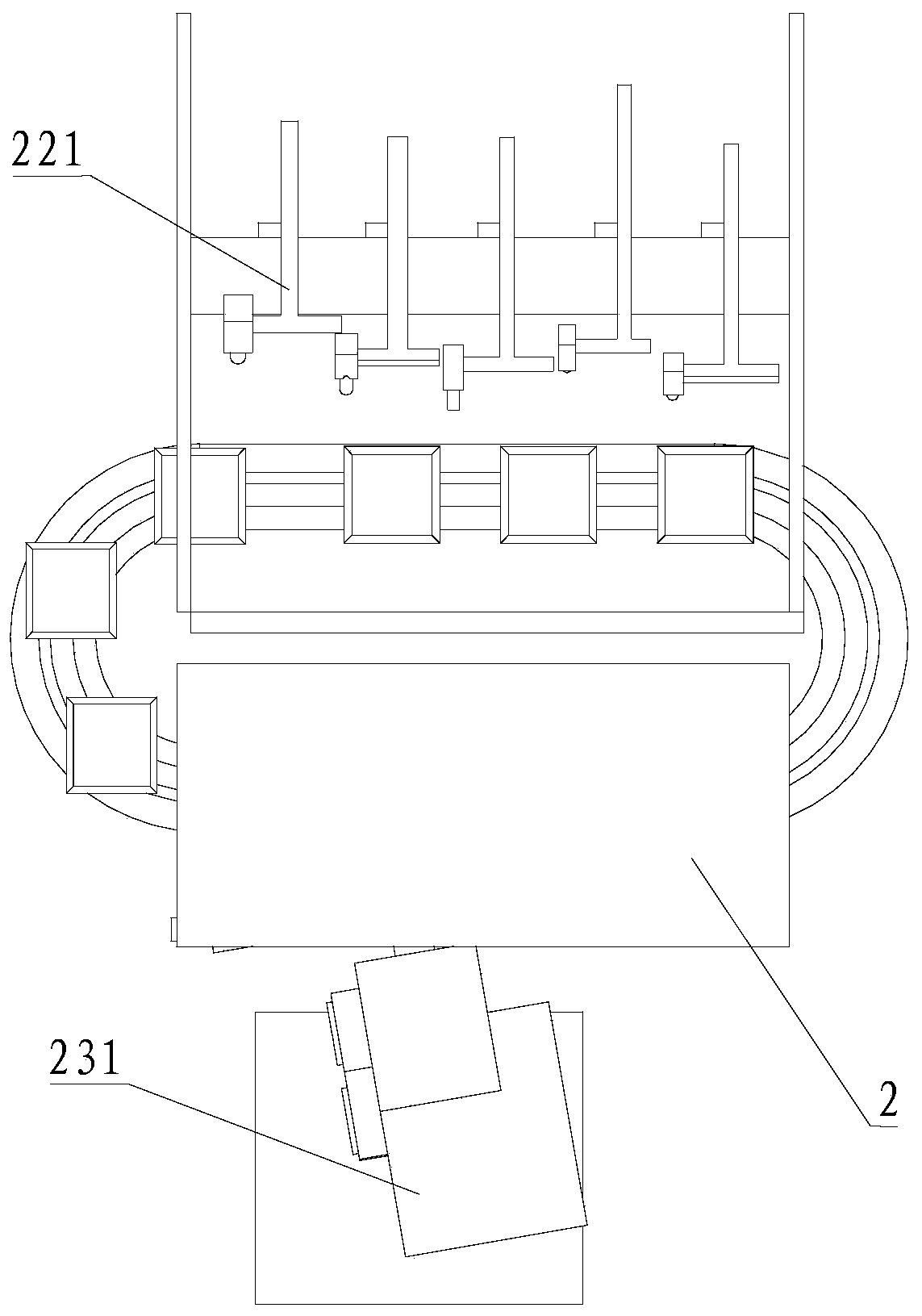

[0050] Please refer to Figure 1 to Figure 4 Shown, embodiment one of the present invention is:

[0051] A fully automatic powder spraying equipment provided by the present invention includes a horizontally distributed conveying chain 1, a powder spraying room 2 erected on the conveying chain and a controller. The conveying chain 1 runs in one direction, such as clockwise, The transmission chain 1 is provided with a mounting block 3, the outer surface of the mounting block 3 is provided with a receiver 4, and one side of the middle part of the transmission chain 1 is provided with a transmitter 5 adapted to the receiver 4, The emission direction of the transmitter 5 is perpendicular to and intersects with the movement direction of the conveyor chain 1, the interior of the installation block 3 is hollow and the interior of the installation block 3 is provided with a forward and reverse motor 6 electrically connected to the receiver 4, The output shaft of the reversible motor 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com