Organic film forming apparatus

A technology of organic film and outer tube, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of sublimation stripping, organic film quality deterioration, large volume, etc., and shorten the cooling time , the effect of maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

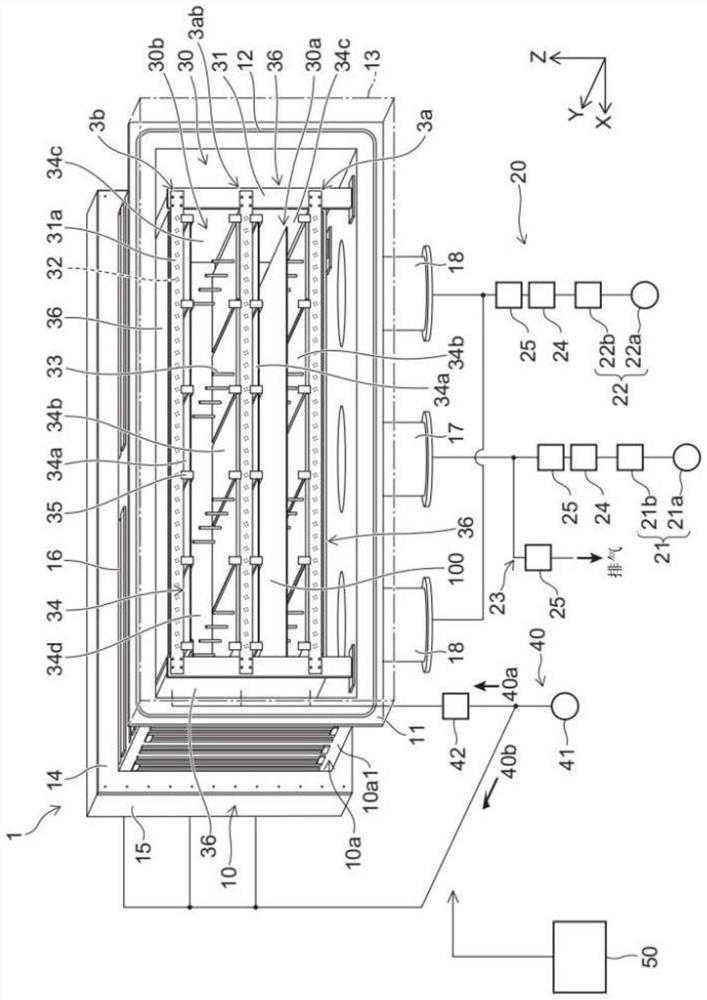

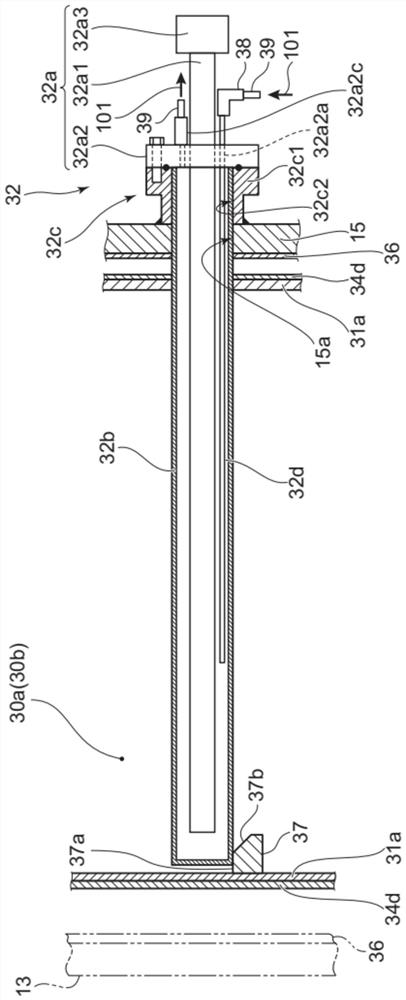

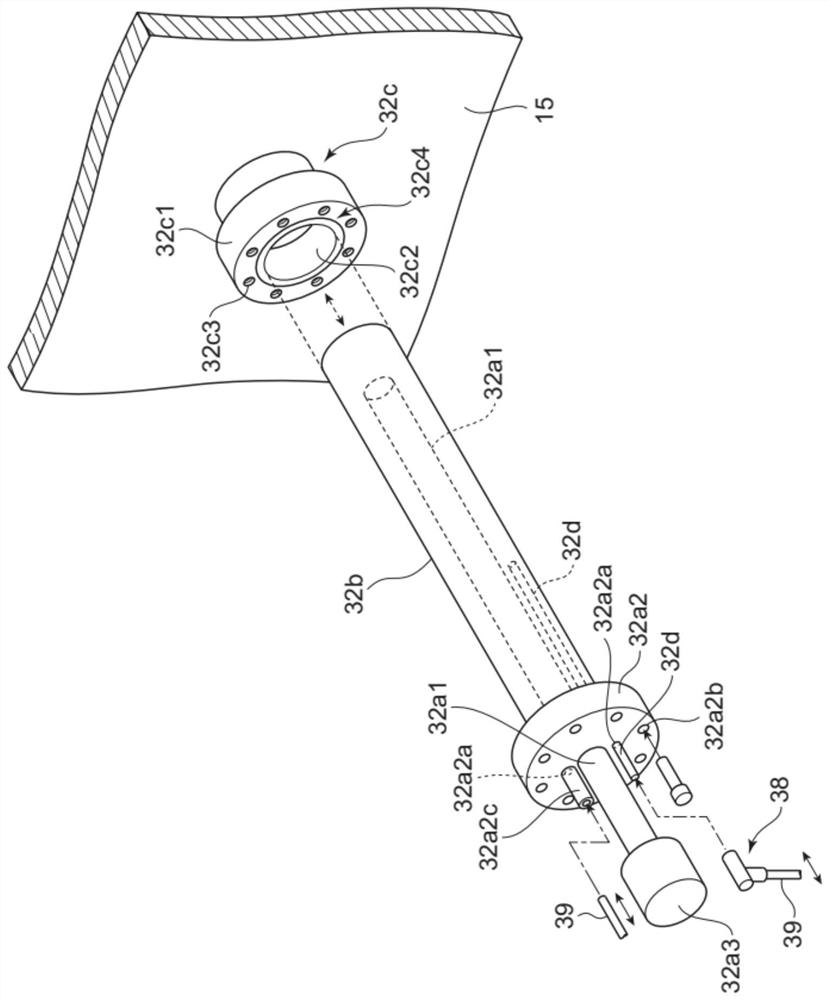

[0023] Embodiments are illustrated below with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same component in each drawing, and detailed description is abbreviate|omitted suitably. In addition, in this embodiment, an organic film forming apparatus capable of forming an organic film by firing a solution containing an organic material coated on the upper surface of a substrate under a reduced-pressure atmosphere will be described.

[0024] figure 1 It is a schematic perspective view for illustrating the organic film formation apparatus 1 which concerns on this embodiment.

[0025] in addition, figure 1 The X direction, the Y direction, and the Z direction represent three directions orthogonal to each other. The up-down direction in this specification may be the Z direction.

[0026] The workpiece 100 has a substrate and a solution coated on the upper surface of the substrate.

[0027] The substrate may be, for example, a glass sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com