A high-precision special-shaped hole processing method

A processing method and high-precision technology, used in metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problems of unstable processing accuracy, inability to meet the high-precision and high-quality processing requirements of aerospace structural parts, and high error rates, achieving Ensure the final forming accuracy and avoid the effect of unstable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

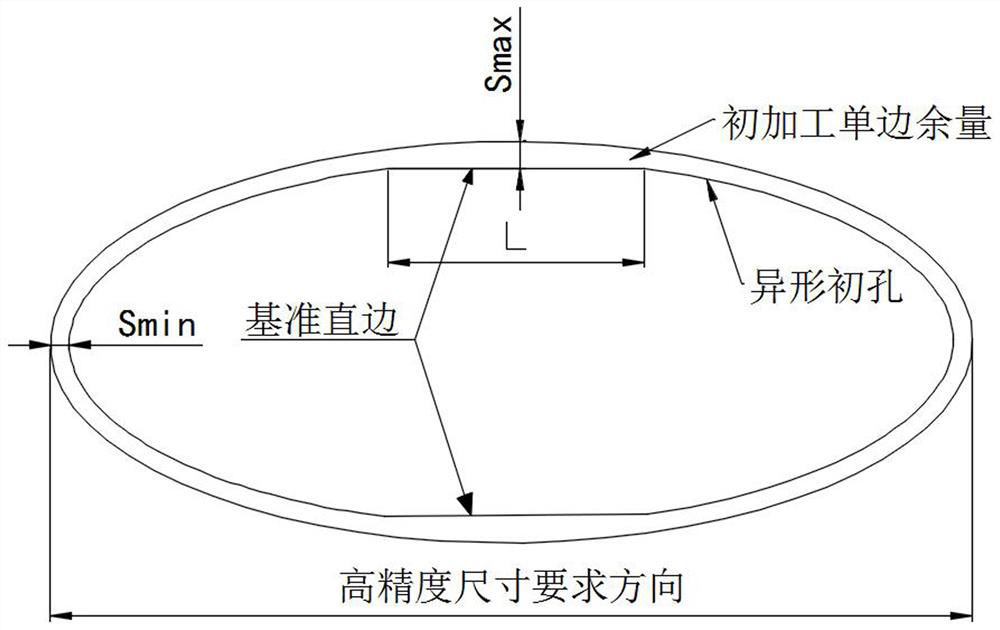

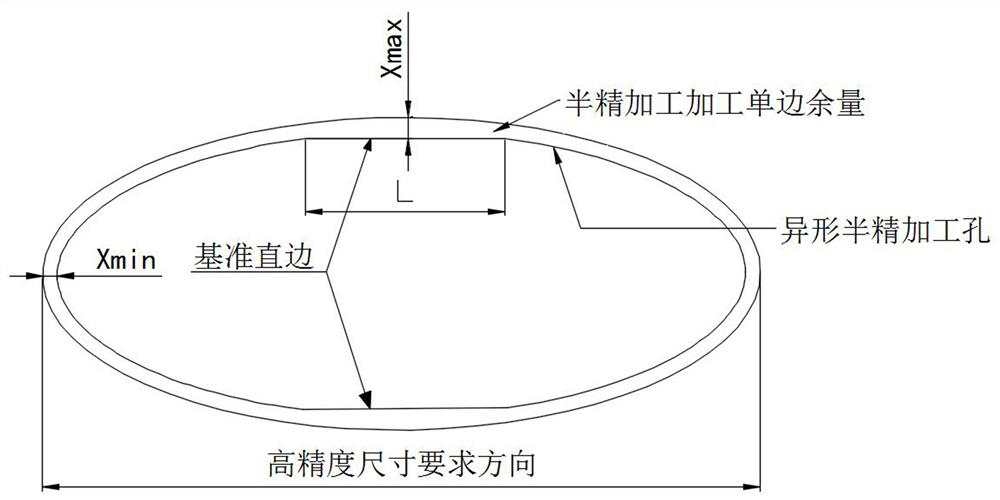

[0034] A kind of high-precision special-shaped hole processing method of the present embodiment, such as figure 1 As shown in Fig. 1, set the reference straight edge on both sides of the special-shaped initial hole parallel to the direction required by the high-precision dimension, and use the reference straight edge as the processing reference to set the preliminary machining single-side allowance for the special-shaped initial hole, and then carry out the initial processing of the special-shaped initial hole. Process to obtain the special-shaped preliminary machining hole; set the semi-finishing unilateral allowance for the special-shaped preliminary machining hole with the reference straight edge as the processing reference, and then perform semi-finishing on the special-shaped preliminary machining hole to obtain the special-shaped semi-finishing hole; use the benchmark on both sides The center line of the distance between the straight sides is used as the benchmark to meas...

Embodiment 2

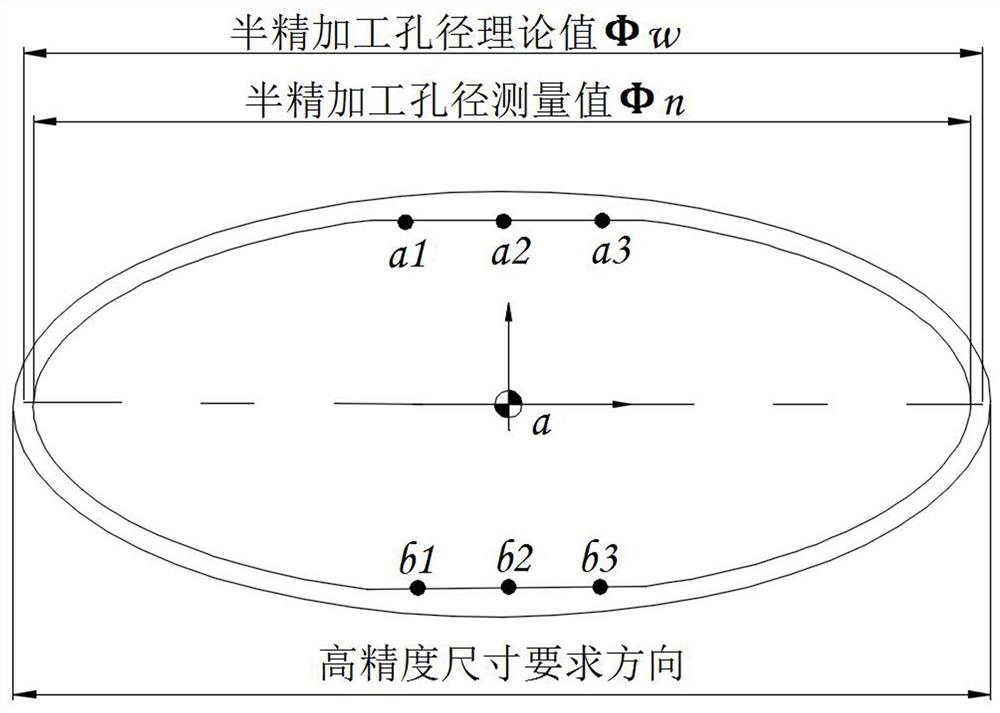

[0036] This embodiment is further optimized on the basis of embodiment 1, such as image 3 As shown, the hole diameter finishing error of the special-shaped semi-finishing hole is measured based on the center line of the distance between the reference straight sides on both sides, which specifically includes the following steps:

[0037] Step A1, randomly select three calibration points on the reference straight edges on both sides, and use the measuring probe to measure the calibration coordinate values of the three calibration points in the direction perpendicular to the high-precision dimension requirement;

[0038] Step A2, calculate the average value of the calibration coordinate values of the three calibration points, and determine the center line of the distance between the reference straight sides on both sides according to the average value of the calibration coordinate values of the reference straight sides on both sides;

[0039] Step A3, using measuring pins ...

Embodiment 3

[0046] This embodiment is further optimized on the basis of the above-mentioned embodiment 1 or 2, and the diameter of the final hole is determined according to the size relationship between the hole diameter finishing error and the tolerance requirement, which specifically includes the following steps:

[0047] Step B1. Obtain the limit upper difference f and the limit lower difference e required by the tolerance, and calculate the median value of the tolerance ;

[0048] Step B2, determining the final hole diameter according to the size relationship between the hole diameter finishing error and the tolerance median;

[0049] Step B3, stepwise adjusting the diameter of the final hole according to the tolerance requirements and preparing a corresponding processing program.

[0050] Further, in step B3, a step adjustment amount is set for the final hole diameter corresponding to each processing program, and the final hole diameter is incrementally enlarged according to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com