Linear tool magazine clamping jaw

A tool magazine claw, straight line technology, applied in the direction of clamping, support, positioning device, etc., can solve the problems of inaccurate positioning of the claw, easy to loosen, low strength, etc., to achieve simple structure, convenient processing, high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings.

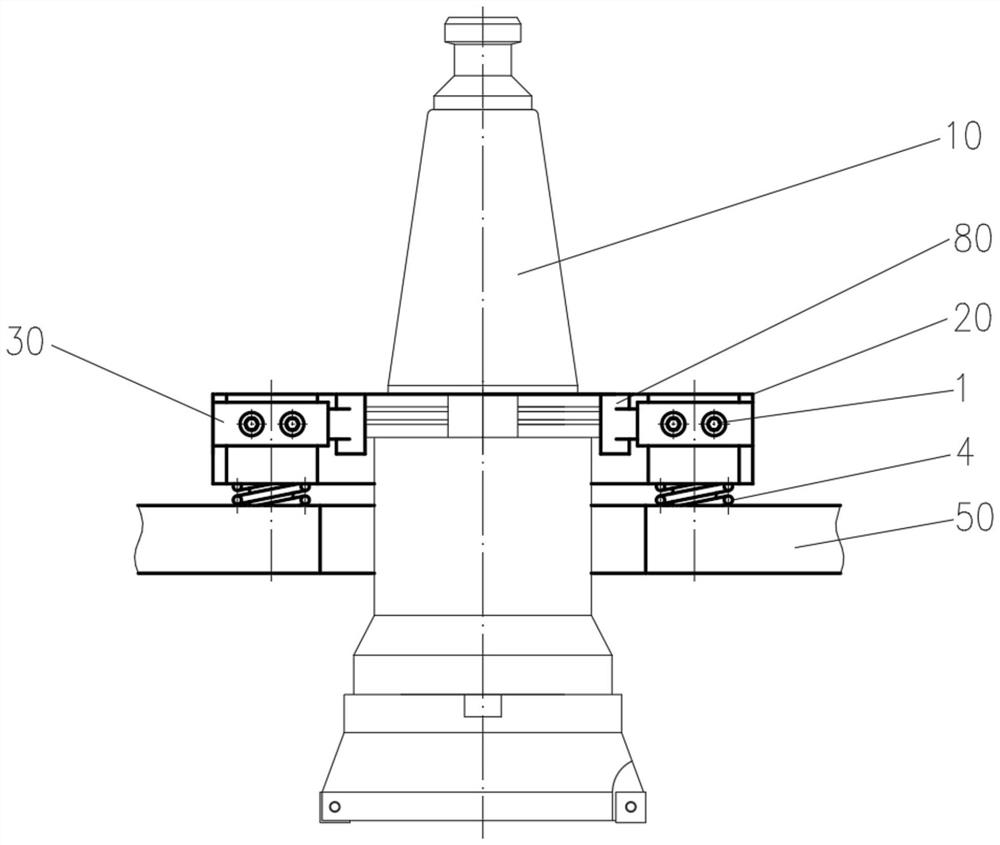

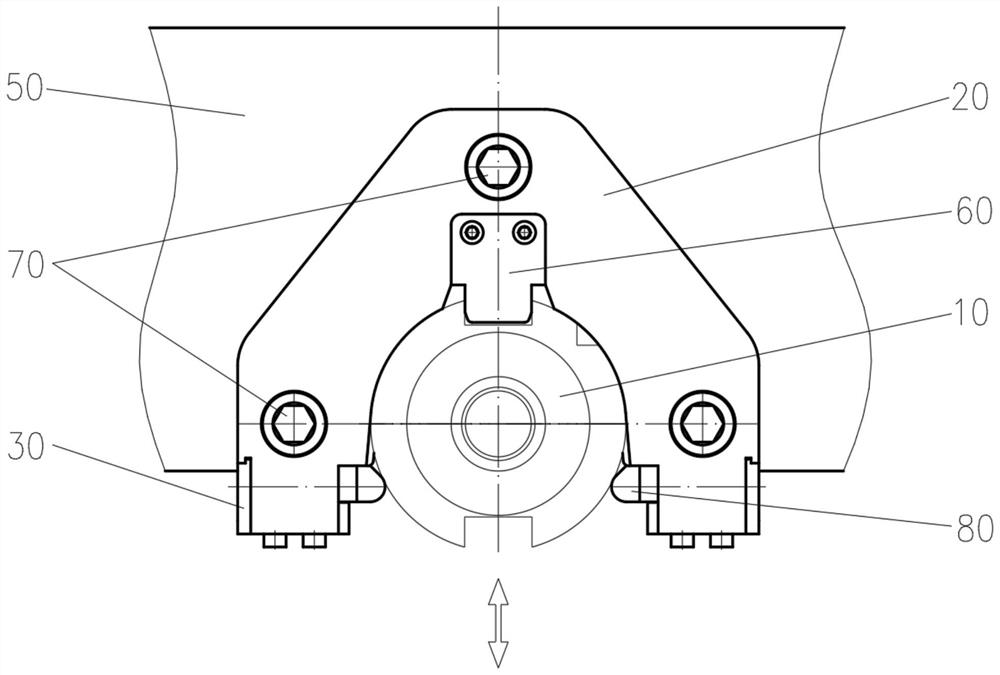

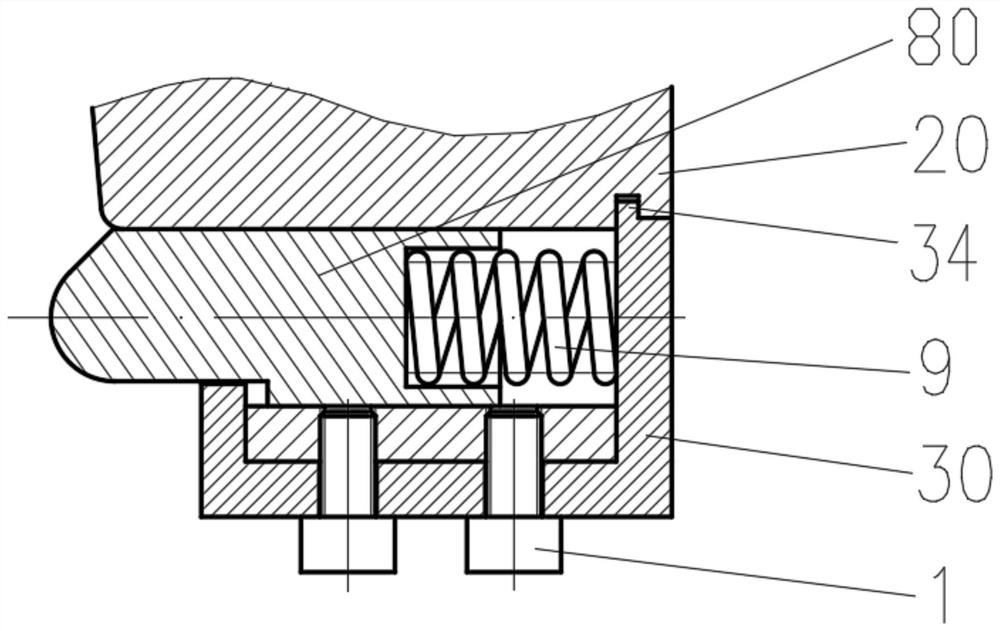

[0041] There are two stop pins 80 at the opening of the jaws of the linear tool magazine of the present invention. Relying on the internal spring 29, the stop pins 80 are provided with elastic force, stretched along the axial direction, and the handle is locked in the tool holder, or the knife is removed. clamp, see figure 1 , figure 2 , image 3 . The body 20 is provided with three stepped holes 23 , and the tool magazine mounting frame 50 is provided with a connecting hole 51 corresponding to the stepped holes 23 . Three position-limiting guide posts 70 pass through three stepped holes 23 on the body 20 , are covered with three springs 4 , and are fixed on the tool magazine installation frame 50 . The limit guide column 70 is installed in the step hole on the body 20, the big head 71 at the upper end of the limit guide column 70 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com