Lateral glue injection device of injection molding machine

An injection molding machine, side-mounted technology, which is applied to the field of the injection device of the side-mounted injection molding machine, can solve the problems of shortening the service life and wear of components, and achieves the effect of reducing the length of the device, reducing the manufacturing cost and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

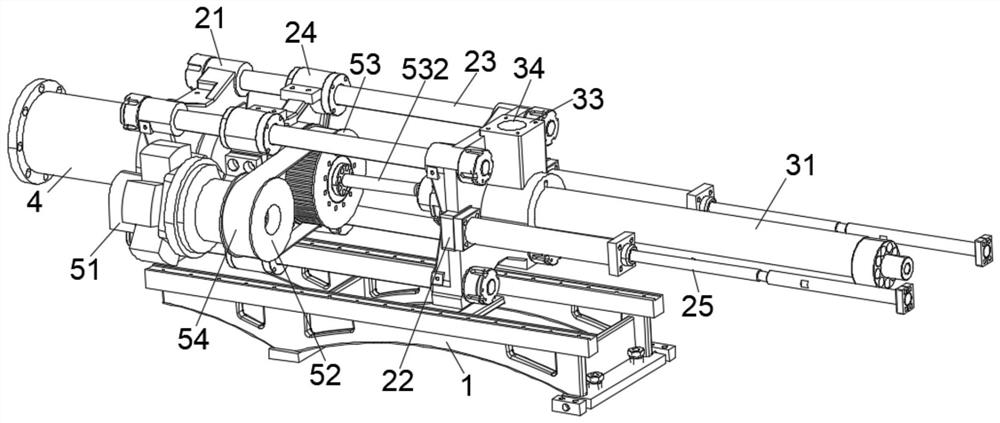

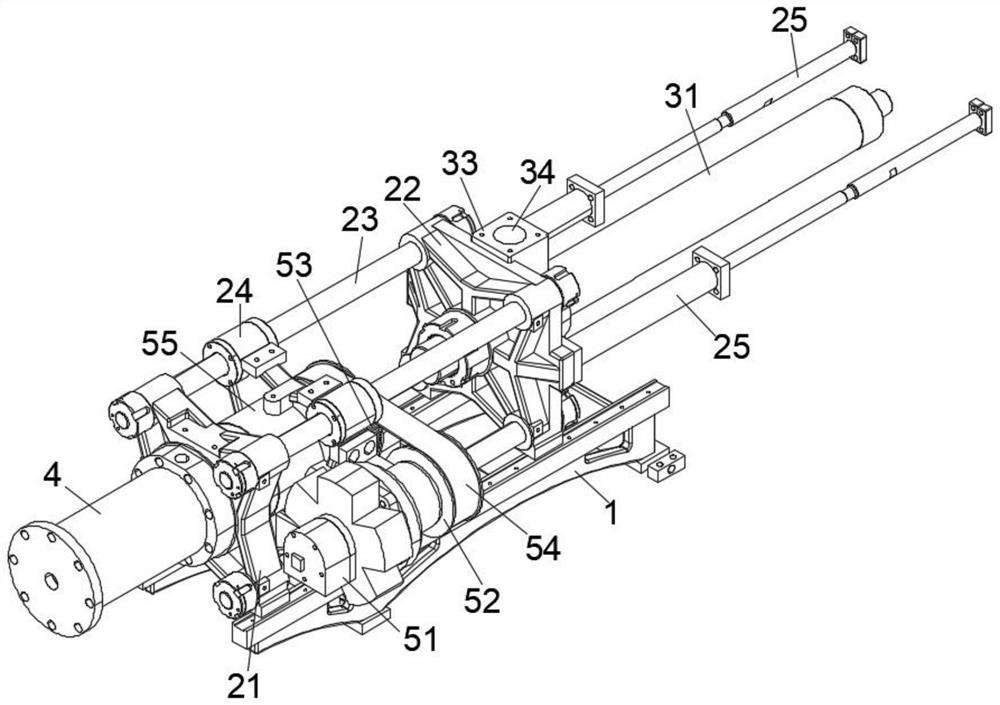

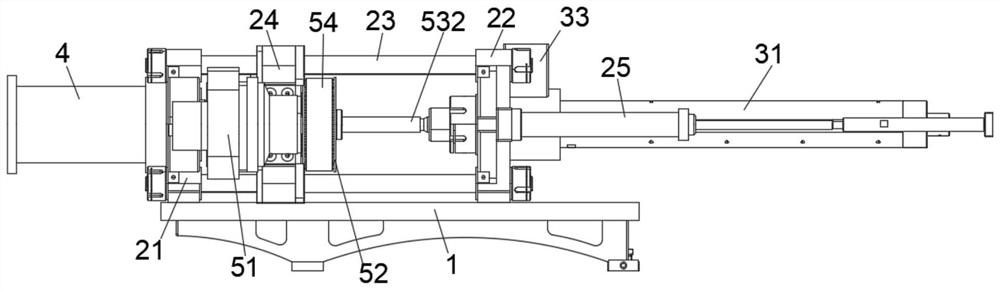

[0026] see Figure 1-5 As shown, the present invention provides a technical solution of a side-mounted injection molding machine injection device: including a base 1, the base 1 is respectively provided with a first fixed seat 21 and a second fixed seat 22, and the first fixed seat 21 and the second fixed seat 22 is connected with a positioning rod 23, the positioning rod 23 is covered with a movable bracket 24, and the movable bracket 24 is provided with a transmission mechanism. Specifically, the transmission mechanism is used to realize the rotary feeding of the injection screw rod 532. The driving part 51 on the side of the support 24, specifically, the driving part 51 can be a hydraulic motor or an electric motor, the output end of the driving part 51 is connected with a driving pulley 52, and the position of the movable support 24 is provided with a connecting seat 55, and inside the connecting seat 55 A bearing 56 is embedded, and a transmission shaft 531 is inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com