Tire and manufacturing method

A technology of tires and dual-purpose tires, which is applied to heavy-duty tires, road vehicle tires, tire parts, etc., and can solve problems such as comparability, impact on tires, casualties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

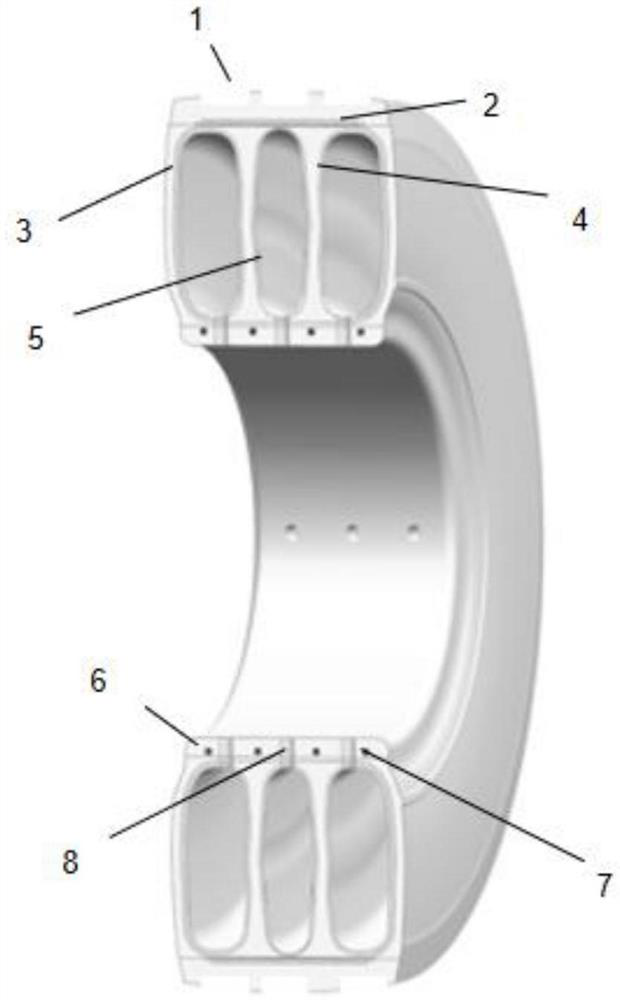

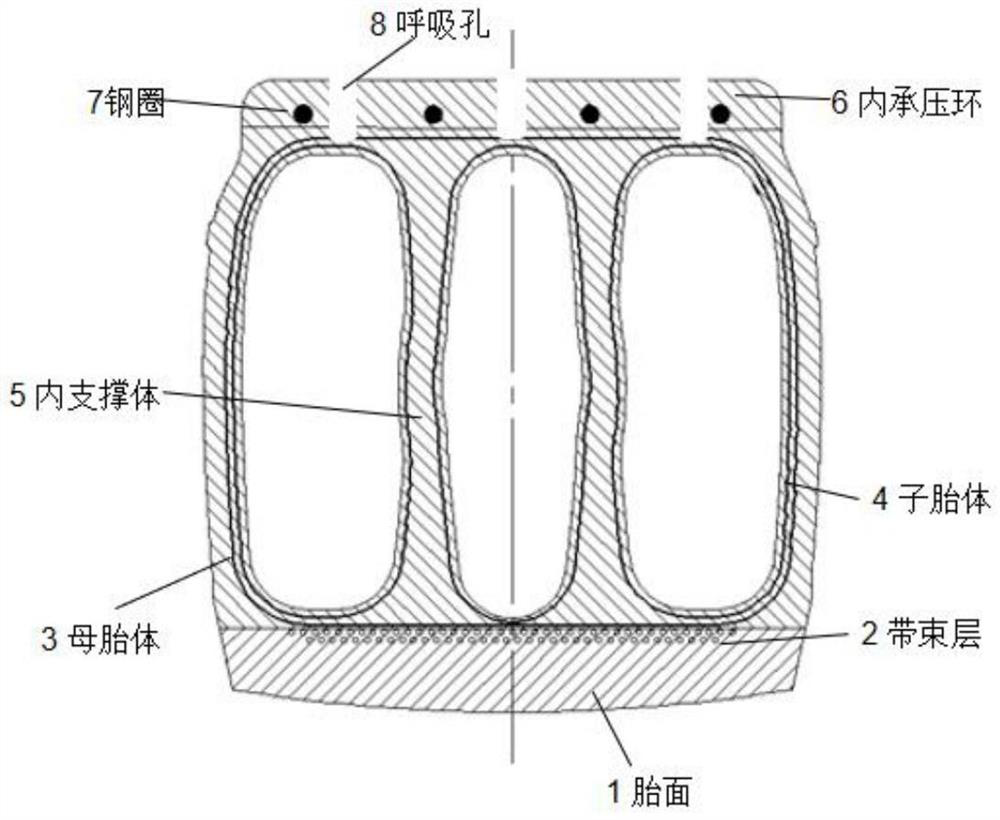

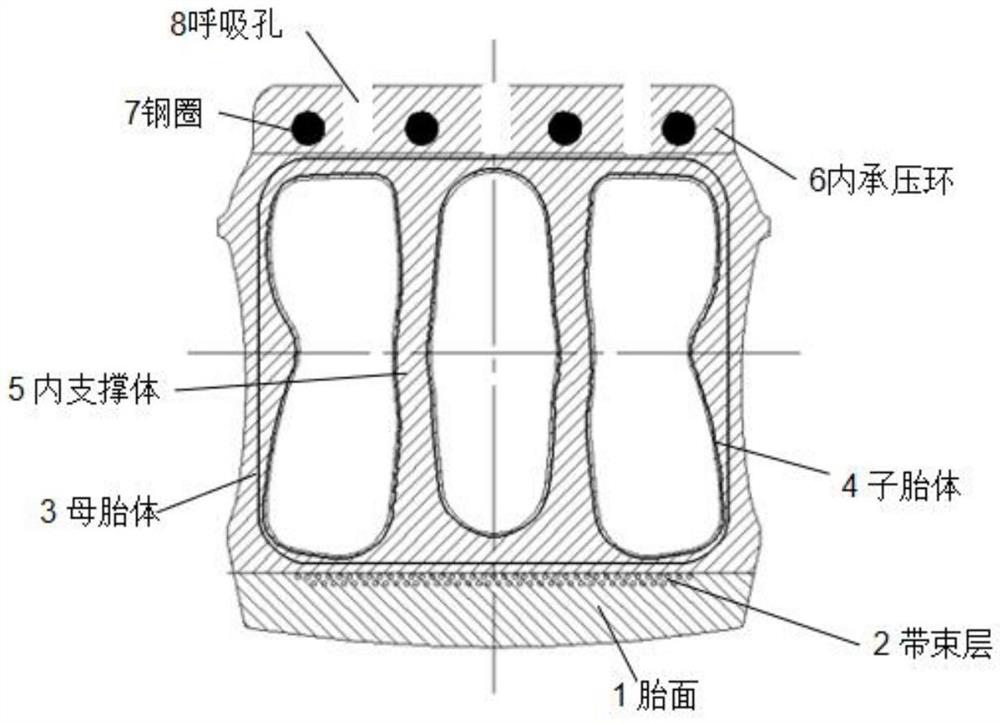

[0085] Take the type II support structure as an example to describe. like figure 1 As shown, there are two circumferential supports inside the tire, and polyurethane is used as the tire manufacturing material. The tire manufacturing method is as follows:

[0086] Steel wire belt layer: Please refer to CN201910815970.X and CN201911421934.1 for the specific process.

[0087] The entanglement of the child and mother's carcass:

[0088] Use special equipment to wind the sub-carcass. When winding, fix one end of the 3+9+15×0.175+0.15NT cord on a single inner core. The wound godet runs continuously through the inner ring of the inner core. When winding, control the gap according to the different requirements of the carcass design. After the winding is completed, the end point is fixed, such as Figure 12 shown. Wind all independent inner cores to complete, such as Image 6 shown.

[0089] Use special equipment to wrap the mother carcass. When winding, fix one end of the 3+...

Embodiment 2

[0095] Taking the polyurethane material with type II support structure as an example, nylon cord is used as the skeleton material of the mother and child carcass cord, and the manufacturing method is as follows:

[0096] Steel wire belt layer: Please refer to CN201910815970.X and CN201911421934.1 for the specific process.

[0097] The entanglement of the child and mother's carcass:

[0098] Use special equipment to wind the sub-carcass. When winding, one end of the polymer fiber (nylon) cord is fixed on a single inner core. The wound godet runs continuously through the inner ring of the inner core. When winding, control the gap according to the different requirements of the carcass design. After the winding is completed, the end point is fixed, such as Figure 12 shown. Wind all independent inner cores to complete, such as Image 6 shown.

[0099] Use special equipment to wrap the mother carcass. When winding, fix one end of the polymer fiber (nylon) cord to the outerm...

Embodiment 3

[0105] Taking tires with support ribs as an example, the manufacturing method is as follows:

[0106] Steel wire belt layer: Please refer to CN201910815970.X and CN201911421934.1 for the specific process.

[0107] The entanglement of the child and mother's carcass:

[0108] Use special equipment to wind the sub-carcass. When winding, fix one end of the 3+9+15×0.175+0.15NT cord on a single inner core. The wound godet runs continuously through the inner ring of the inner core. When winding, control the gap according to the different requirements of the carcass design. After the winding is completed, the end point is fixed, such as Figure 12 shown. Wind all independent inner cores to complete, such as Image 6 shown.

[0109] Use special equipment to wrap the mother carcass. When winding, fix one end of the 3+9+15×0.175+0.15NT cord to the outermost ring of the inner core. The cord is wound around several cores, passing the wound godets continuously through the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com