An aircraft test comprehensive climate environment simulation system and simulation method

A climate environment and simulation method technology, applied in the direction of aircraft component testing, can solve the problems of high resource consumption, difficult organization and coordination, long test cycle, etc., and achieve low investment and operating costs, good scalability, and flexible system use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

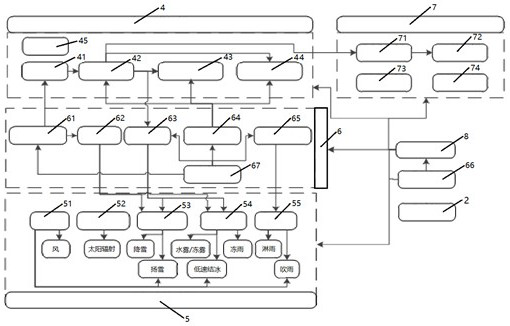

[0106] This embodiment is a kind of aircraft test comprehensive climate environment simulation system, such as figure 1 shown, including:

[0107] Test machine 1, test machine 1 is an airplane,

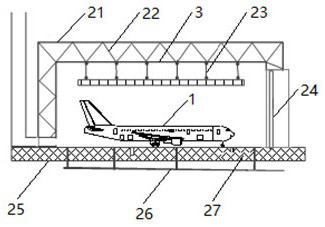

[0108] The laboratory structure system for carrying the testing machine 1, the laboratory structure system includes: a sealed insulation cabin 3, a building structure 2 for fixing the insulation cabin 3 and serving as the laboratory skeleton, the insulation cabin 3 adopts a thickness of 200mm Made of polyurethane sandwich panels, such as figure 2 As shown, the building structure 2 includes from the inside to the outside: a steel structure 22, an outer wall surface 21, a hoisting module 23 on the inner top of the steel structure 22, a bearing ground 25 on the inner bottom of the steel structure 22, and a ground on the bearing ground 25. Drainage 26 and ground mooring 27, the side of building structure 2 is also provided with gate 24,

[0109] The environment simulation system used ...

Embodiment 2

[0118] The present embodiment is the simulation method of a kind of aircraft test comprehensive climate environment simulation system based on embodiment 1, such as Figure 5 shown, including the following steps:

[0119] S1. Low temperature environment simulation

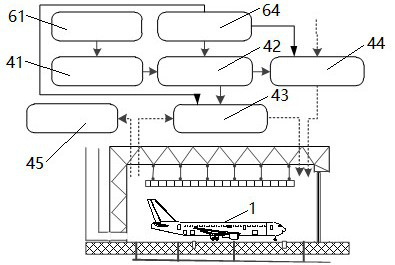

[0120] S1-1. Start the cooling water module 61, the steam boiler 64, and the air supply module 62. The cooling water module 61 is used for heat dissipation of the refrigeration module 41 and the air supply module 62. The steam boiler 64 provides a heat source for the regeneration of the dehumidification and fresh air module 44 of the runner. The air supply module 62 provides high-pressure air for the pneumatic actuator;

[0121] S1-2. Start the air circulation processing module 43, the wheel dehumidification fresh air module 44, the micro positive pressure device 45, the cooling and heating module 42 and the refrigeration module 41 in sequence;

[0122] S1-3. The refrigeration module 41 provides a cold source, an...

Embodiment 3

[0187] The difference between this embodiment and embodiment 1 is:

[0188] The insulation cabin body 3 adopts the polyurethane sandwich panel that thickness is 240mm to make.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com