Pallet carrying AGV trolley and using method thereof

A technology of pallets and trolleys, applied in the directions of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of high manufacturing cost, weak flexibility, and space occupation of trolleys, and achieve low cost, simple action, The effect of small site occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

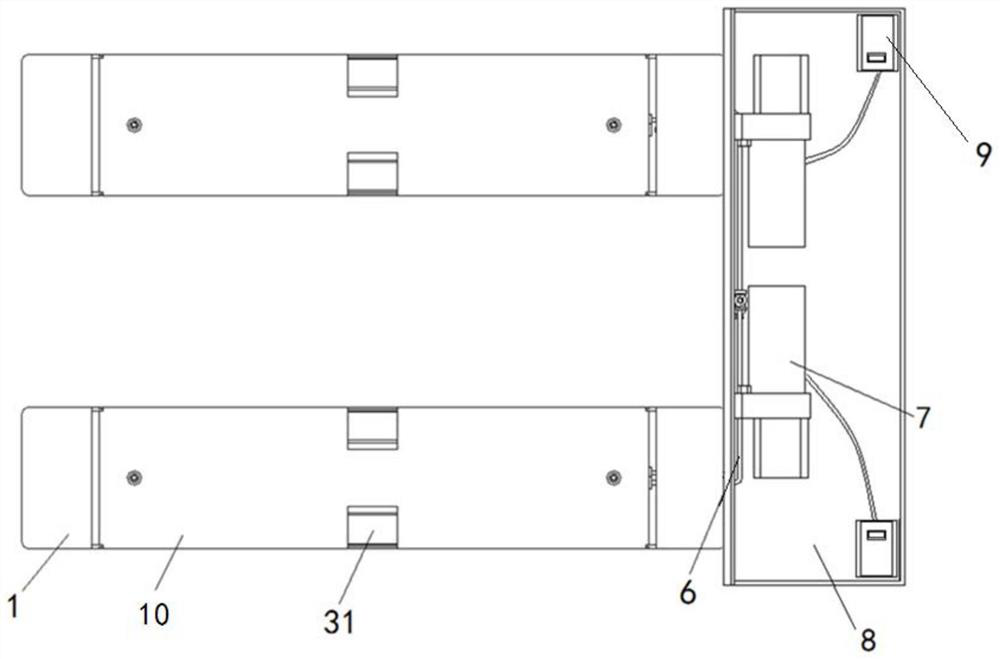

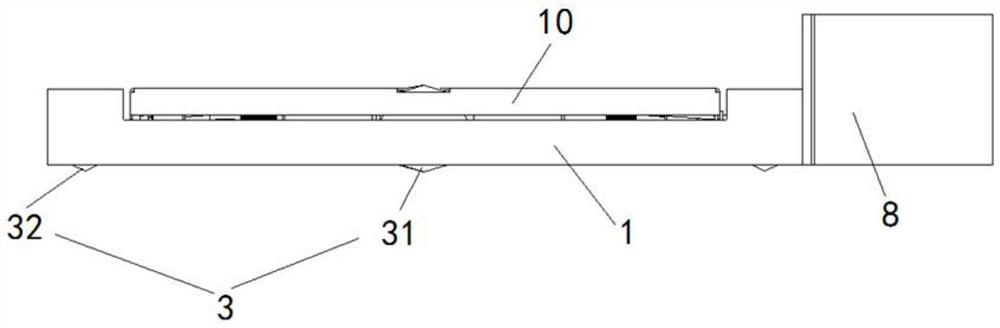

[0052] A pallet handling AGV trolley, such as Figure 1~2 As shown, it includes two parallel bearing plates 1 arranged at intervals, the two bearing plates 1 are connected by a connecting mechanism, and each bearing plate 1 is provided with a wheel set mechanism 3 and a lifting plate 10, wherein the wheel set mechanism 3 includes The driving wheel 31 arranged in the middle of the carrying plate 1 and the universal driven wheel 32 arranged at the front and rear ends of the carrying plate 1 . The lifting plate 10 is provided with a slot for the driving wheel 31 to pass through.

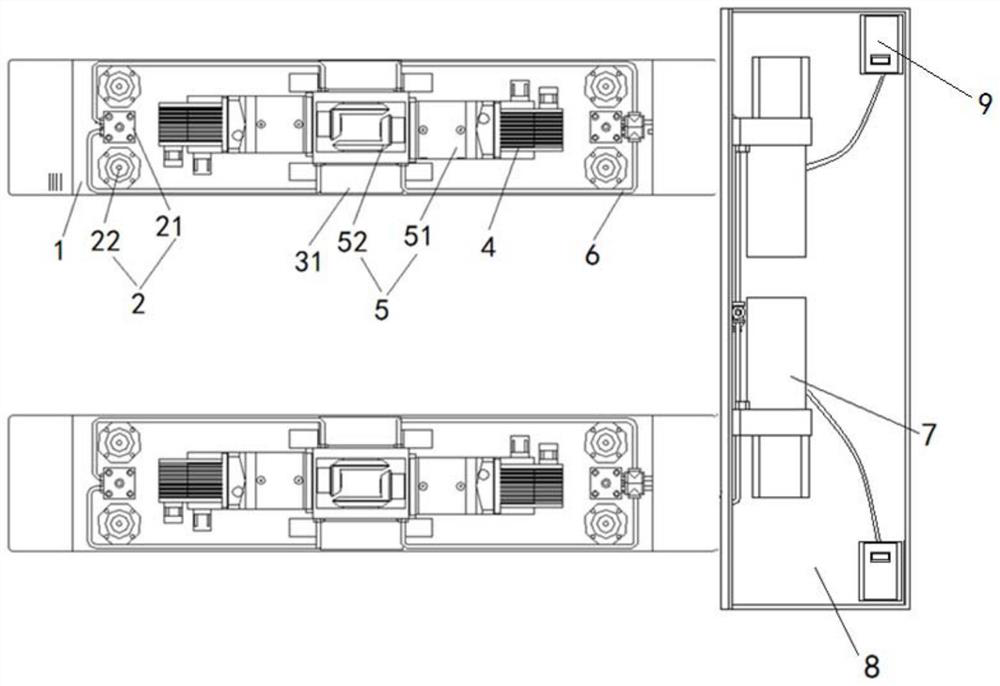

[0053] Specifically, such as Figure 3-4 As shown, the front and rear ends of the load plate 1 (based on the direction of travel of the trolley) are provided with a jacking mechanism 2 for realizing the lifting of the jacking plate 10. Each jacking mechanism 2 includes a hydraulic cylinder 21 and two hydraulic cylinders 21. The guide assembly 22 on the side and the hydraulic cylinder 21 on the same be...

Embodiment 2

[0061] In this embodiment, the guide assembly is a linear bearing, and the rest of the structure is the same as that of Embodiment 1.

Embodiment 3

[0063] A pallet handling AGV trolley, such as Figure 6-8 As shown, a bearing plate 1 is included, and a hydraulic pump 7 and a base 8 are also arranged on the bearing plate 1 . The machine base 8 and the bearing plate 1 are integrally formed, the height of both ends of the bearing plate 1 is the same, and the rest of the structure is the same as that of the first embodiment.

[0064] When using the AGV trolley of this embodiment to carry pallets, the control mechanism controls the operation of each driving mechanism 4 to drive the driving wheels 31 on the left and right sides of the load plate 1 to rotate, and the AGV trolley is transported to the pallet stacking place, and then the load plate 1 is inserted into the pallet Under the board, the hydraulic cylinder 21 drives the lifting board 10 to rise, and the pallet is lifted up for transportation. After reaching the designated position, the hydraulic cylinder 21 drives the lifting board 10 to descend, and the pallet is put d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com