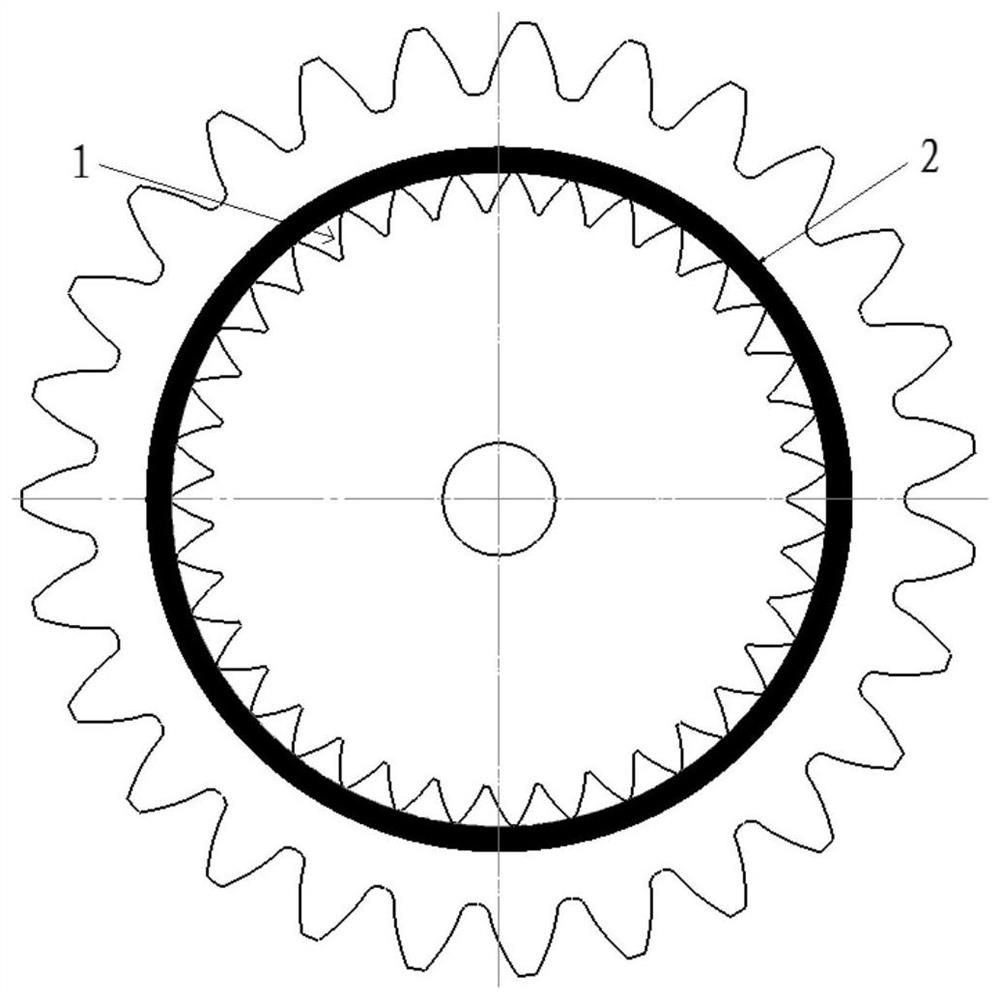

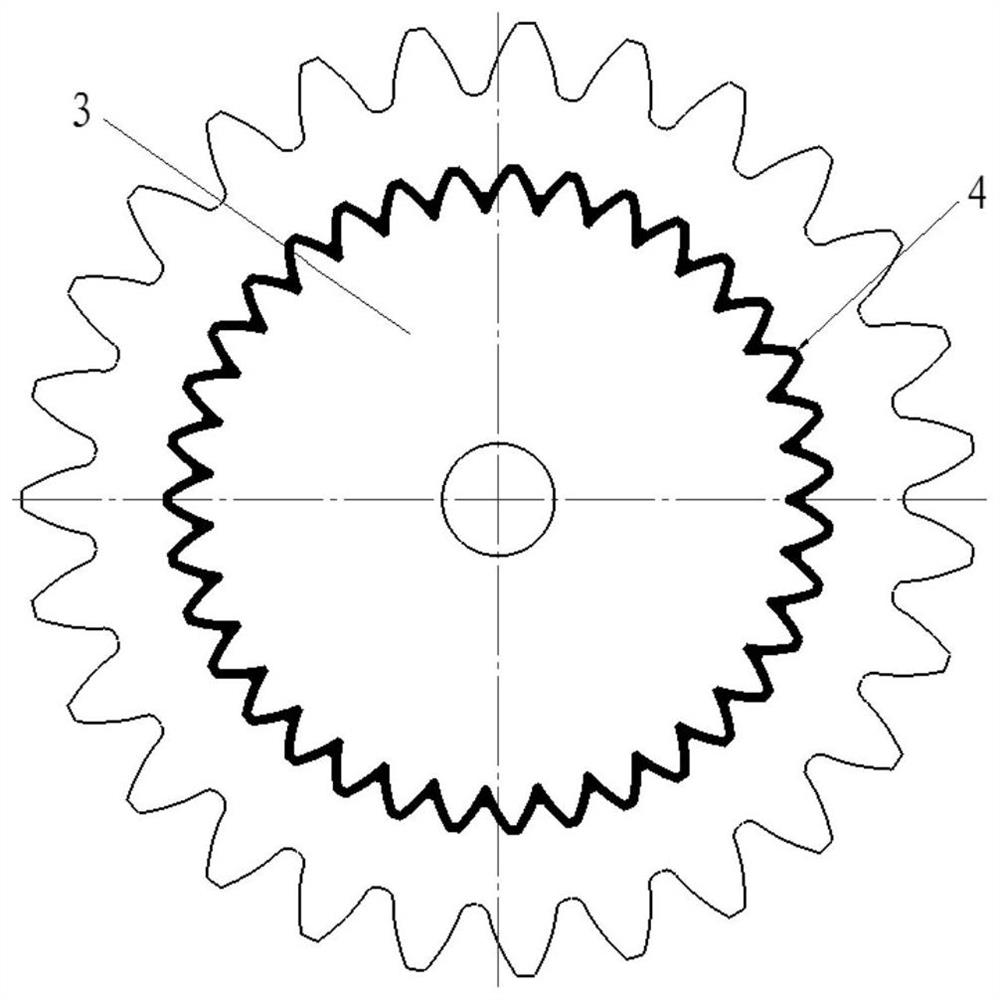

Method for controlling hardness of spline after carburizing and integral quenching of gear

A technology of overall quenching and hardness control, applied in the direction of heat treatment process control, manufacturing tools, improvement of process efficiency, etc., can solve the problem of high surface hardness of splines, reduce the difficulty of finishing and improve the quality of gear products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment includes the following steps:

[0042] Step 1. Die forging the cylindrical steel raw material after heating to obtain a forged gear blank; the material of the cylindrical steel raw material is 17Cr2Ni2MoA low-carbon alloy steel; The temperature is 880°C;

[0043] Step 2: Normalizing and high-temperature tempering the forged blank of the gear part obtained in Step 1 in sequence to obtain a blank; the temperature of the normalizing is 930°C, and the temperature of the high-temperature tempering is 650°C;

[0044] Step 3: Carry out hobbing and contour processing on the blank obtained in step 2 to obtain a green body; during the hobbing and contour processing, a machining allowance is reserved at the spline; the reserved machining allowance at the spline satisfies : The thickness of the machining allowance is 3.8mm;

[0045] Step 4. Carburizing the blank obtained in step 3 to obtain a carburized gear blank; the carburizing uses a nitrogen-methanol carburiz...

Embodiment 2

[0054] This embodiment includes the following steps:

[0055] Step 1. Die forging the cylindrical steel raw material after heating to obtain a forged gear blank; the material of the cylindrical steel raw material is 18CrMnNiMoA low-carbon alloy steel; The temperature is 900°C;

[0056] Step 2. Carrying out normalizing and high-temperature tempering in turn on the forged gear blank obtained in step 1 to obtain a blank; the normalizing temperature is 920°C, and the high-temperature tempering temperature is 670°C;

[0057] Step 3: Carry out hobbing and contour processing on the blank obtained in step 2 to obtain a green body; during the hobbing and contour processing, a machining allowance is reserved at the spline; the reserved machining allowance at the spline satisfies : The thickness of the machining allowance is 4.9mm;

[0058] Step 4. Carburizing the blank obtained in step 3 to obtain a carburized gear blank; the carburizing uses a nitrogen-methanol carburizing atmosphere...

Embodiment 3

[0067] This embodiment includes the following steps:

[0068] Step 1. Die forging the cylindrical steel raw material after heating to obtain a forged gear blank; the material of the cylindrical steel raw material is 18Cr2Ni4WA low-carbon alloy steel; the initial forging temperature in the die forging process is 1180°C, The temperature is 860°C;

[0069] Step 2: Perform normalizing and high-temperature tempering on the forging blank of the gear part obtained in step 1 in sequence to obtain a blank; the temperature of the normalizing is 950°C, and the temperature of the high-temperature tempering is 630°C;

[0070] Step 3: Carry out hobbing and contour processing on the blank obtained in step 2 to obtain a green body; during the hobbing and contour processing, a machining allowance is reserved at the spline; the reserved machining allowance at the spline satisfies : The thickness of the machining allowance is 2.9mm;

[0071] Step 4. Carburizing the blank obtained in step 3 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com