Equipment for rapidly separating feather fibers from feathers

A technology for feather fibers and feathers is applied in the field of equipment for rapidly separating feather fibers, which can solve the problems of insufficient supply of textile raw materials and efficient utilization of waste feathers, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

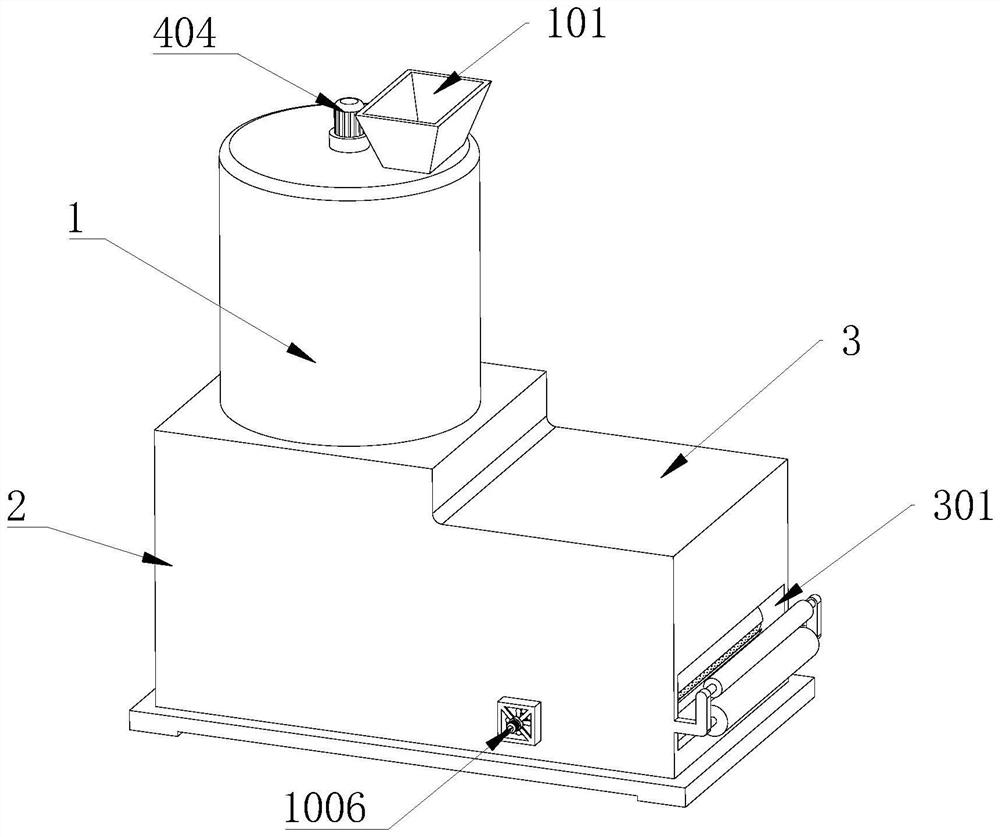

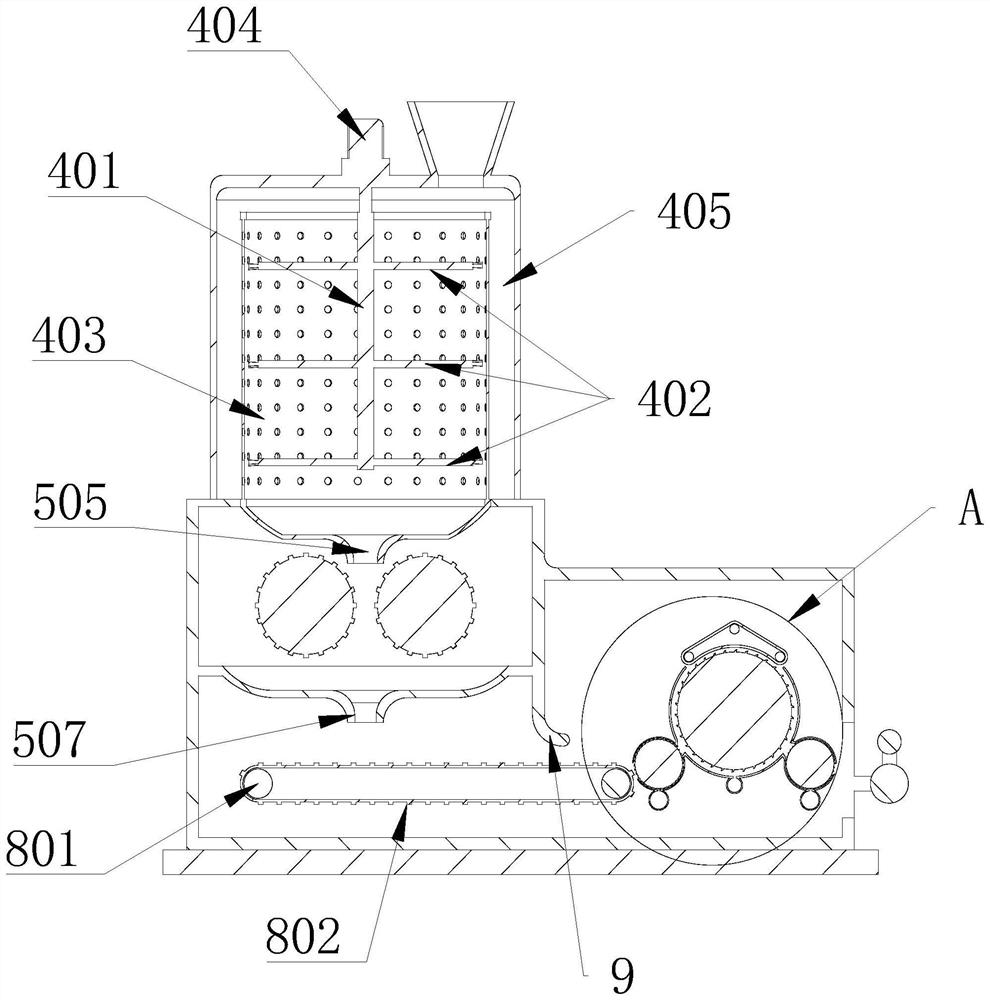

[0034] Example: such as Figure 1-Figure 2 Shown, a kind of equipment that separates feather fiber rapidly from feather, comprises first casing 1, second casing 2, the 3rd casing 3, stirring mechanism, rolling mechanism and separating mechanism, described first casing 1. A feeding port 101 is provided at the upper end, and the feeding port 101 is located on the side of the first motor 404;

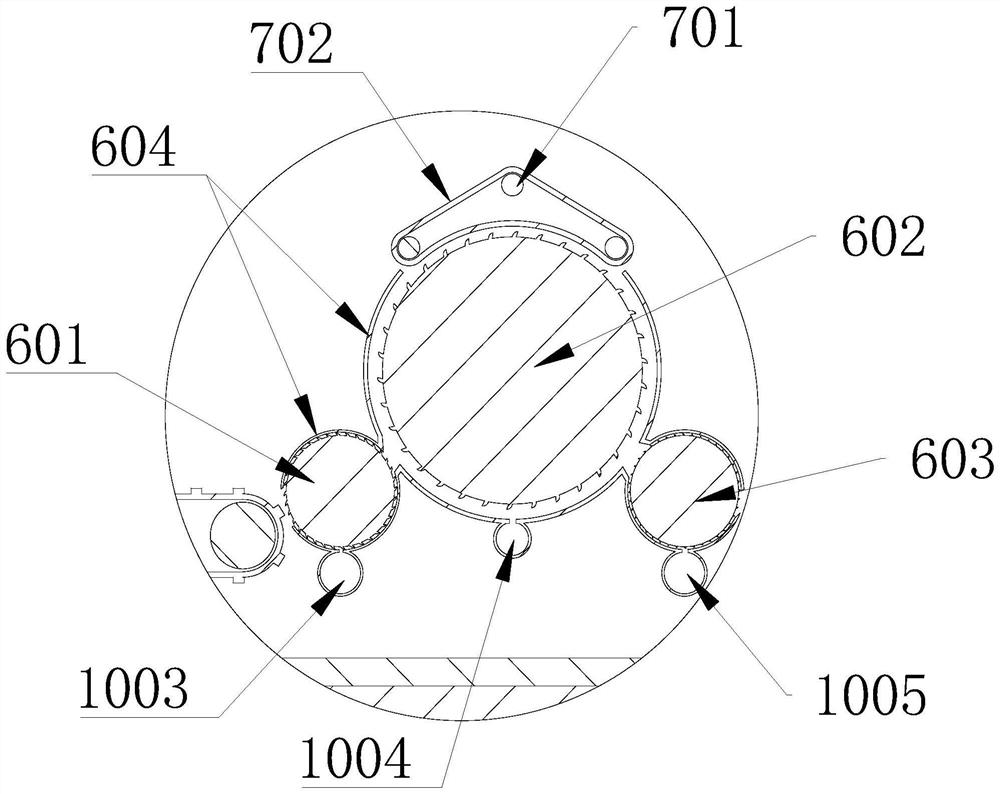

[0035] Among them such as Figure 4-Figure 5As shown, the stirring mechanism, in order to uniformly stir the feathers and remove impurities, utilizes the stirring mechanism located in the first housing 1, including a rotating shaft 401, a rotating rod 402 and an isolation net 403, and the rotating shaft 401 is located at Inside the first housing 1, a first motor 404 is provided at the top of the first housing 1, the output end of the first motor 404 is connected to the top of the rotating shaft 401, and several rotating rods 402 are evenly distributed On the shaft body of the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com