Celadon roller forming equipment with multiple pressing dies and working method

A technology of rolling forming and compression molding, which is applied in the direction of auxiliary forming equipment, ceramic forming machines, pressing rollers, etc. It can solve the problems of reducing safety, reducing production range, and crushing injuries of operators, so as to improve the load capacity and avoid equipment damage. The effect of crushing and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

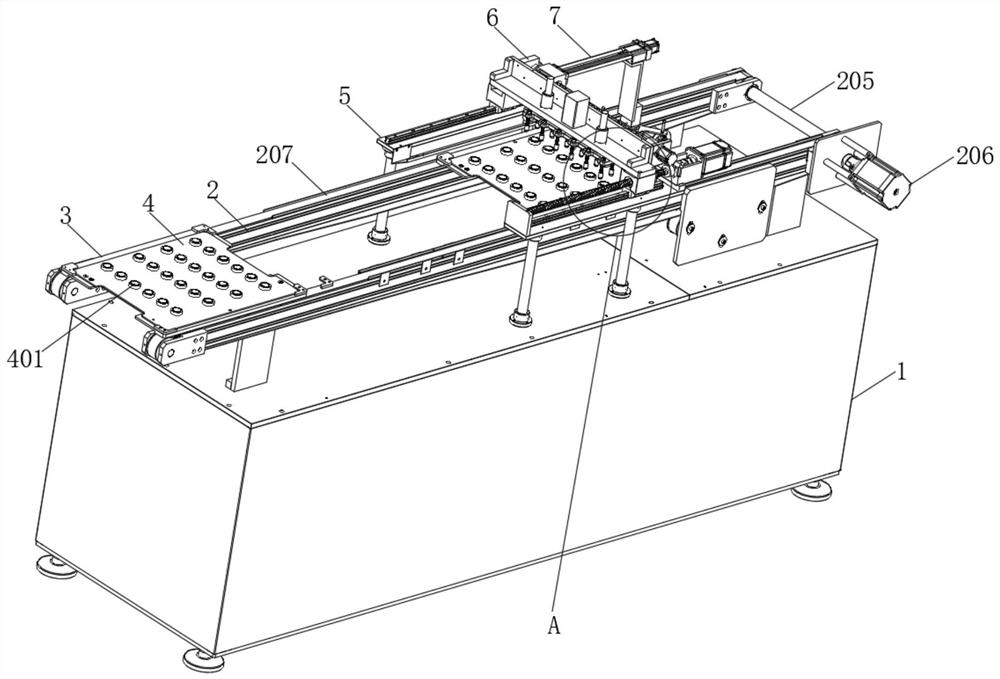

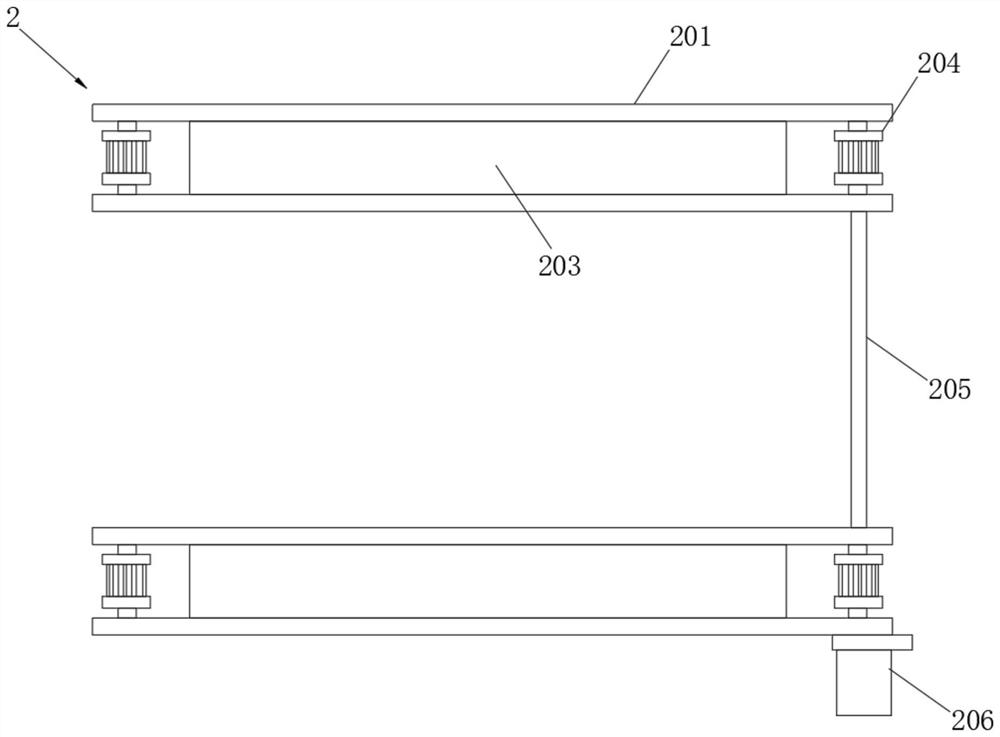

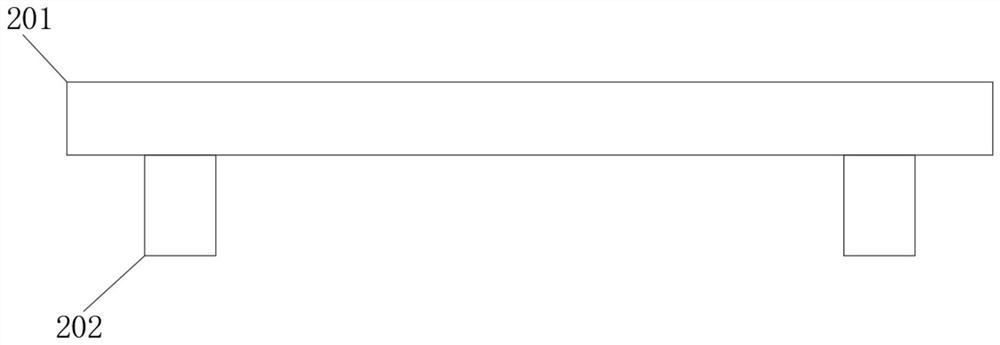

[0036] like Figure 1-Figure 9As shown, the celadon rolling forming equipment for a multi-head die according to the present invention includes a base 1, a conveying assembly 2, a plurality of carrying trays 3, a plurality of object carriers 4, a pressing assembly 5, and a moving assembly 6 and rolling assembly 7, a transfer assembly 2 is installed on the top of the base 1, the equipment makes the process of celadon roll forming more streamlined by using the transfer assembly 2, at the same time, the pressing assembly 5 is used to press the groove, and the rolling The pressing component 7 is rolled and formed. On the one hand, by using this equipment, the entire celadon rolling forming process does not require manual intervention, saving manpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com