Electromagnetically actuatable valve

A technology of electromagnetism and valve seat, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of design pre-control and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

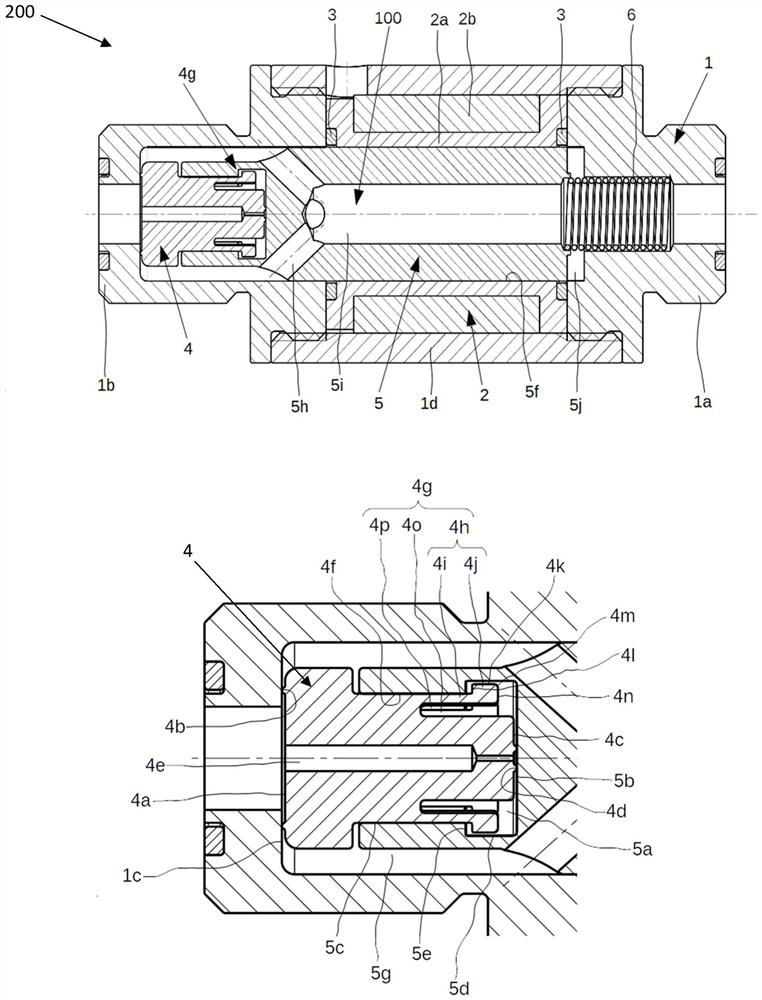

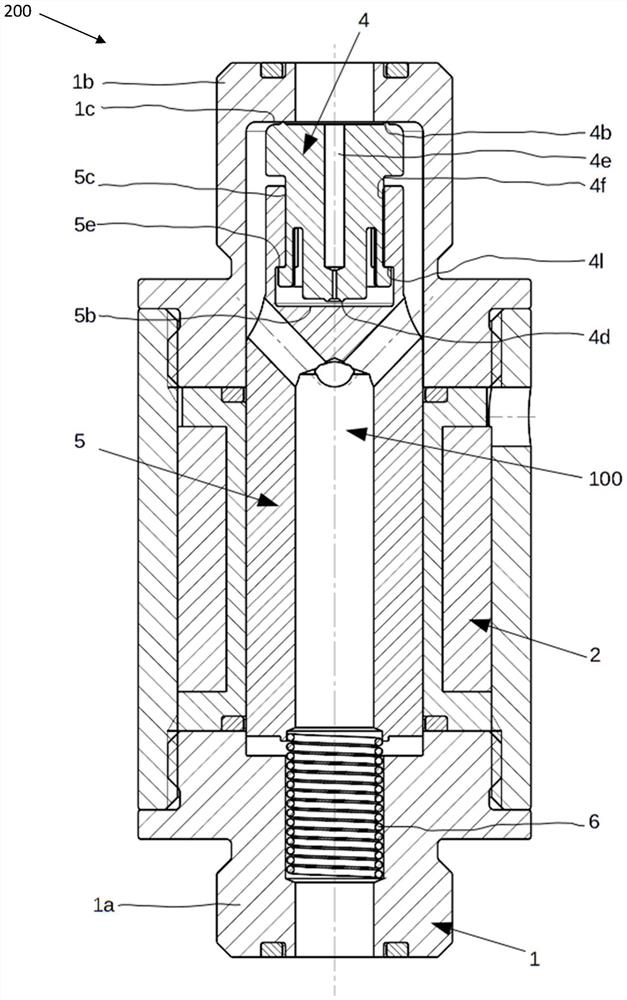

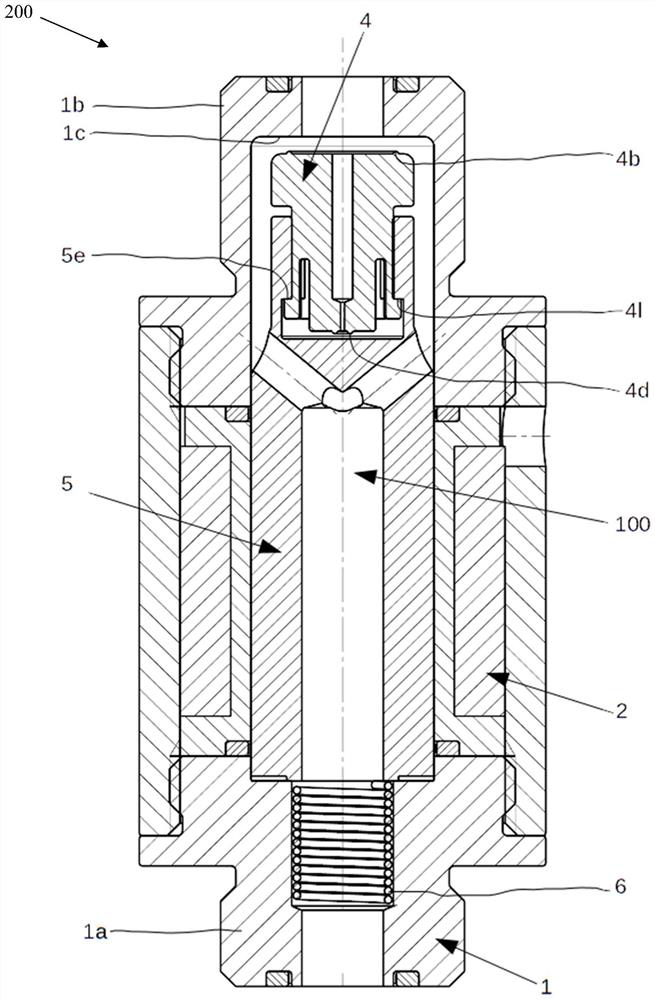

[0016] figure 1 The shut-off system 100 and a part of the shut-off system 100 are shown in the shut-off state in a solenoid straight-through valve 200 for connecting pressure lines on both sides with a multi-component housing 1 of magnetic material , the housing with inlet 1a as pressure connection on the input side, outlet 1b as pressure connection on the output side, valve seat 1c for sealing against the shut-off system 100 and as connection of the two pressure connections 1a, 1b Circuit 1d with a helical thread at both ends and with a magnetic coil 2 with a coil body 2a made of non-magnetic material and a winding 2b made of enamelled wire, wherein the magnetic coil 2 is arranged in The seals 3 on both sides seal against the adjoining parts of the housing 1 .

[0017] The shut-off system 100 is arranged inside the housing 1 or the magnetic coil 2 and comprises a sealing body 4 , an armature 5 and a shut-off spring 6 which acts as an independently operable due to the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com