Asymmetric photonic crystal film capable of changing colors along with angles as well as preparation method and application of asymmetric photonic crystal film

A photonic crystal and varicolor technology, which is applied in the field of asymmetrical photonic crystal film and its preparation, and achieves the effects of improving anti-counterfeiting ability, easy operation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

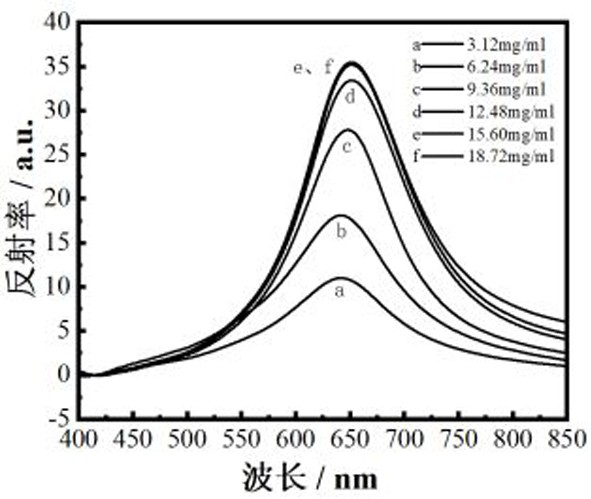

[0043] (1) Fe with a particle size of 160nm 3 o 4 @PVP magnetic nanoparticles are dispersed into a mixture composed of monomer hydroxyethyl methacrylate (HEMA), crosslinker ethylene glycol dimethacrylate (EGDMA), photoinitiator 2-hydroxy-2-methyl-1-benzene In the prepolymerization liquid that hydroxyacetone (HMPP) forms, the concentration of HEMA in the prepolymerization liquid is 0.899g / mL, and the concentration of HMPP is 3.84% of monomer HEMA quality, and the concentration of EGDMA is 14.6% of monomer HEMA monomer, Fe 3 o 4The concentrations of @PVP magnetic nanoparticles are 3.12mg / ml, 6.24mg / ml, 9.36mg / ml, 12.48mg / ml, 15.60mg / ml, 18.72mg / ml respectively.

[0044] (2) Coating different Fe on the surface of the substrate 3 o 4 The pre-polymerization solution with the concentration of @PVP magnetic nanoparticles is cured with a UV lamp for 60s in a vertical uniform magnetic field of 300 Gs (the direction of the magnetic field is perpendicular to the surface of the subst...

Embodiment 2

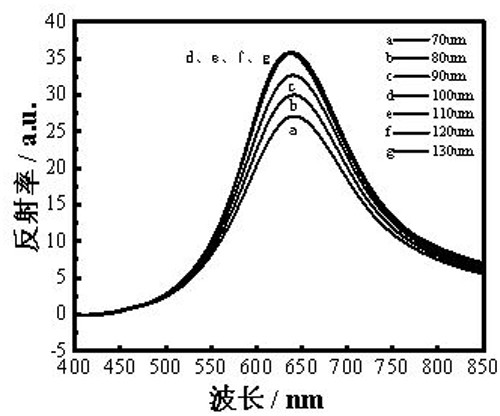

[0047] (1) Fe with a particle size of 160nm 3 o 4 @PVP magnetic nanoparticles are dispersed into a mixture composed of monomer hydroxyethyl methacrylate (HEMA), crosslinker ethylene glycol dimethacrylate (EGDMA), photoinitiator 2-hydroxy-2-methyl-1-benzene In the pre-polymerization liquid composed of methyl acetone (HMPP), Fe 3 o 4 The concentration of @PVP is 15.60mg / ml, the concentration of HEMA is 0.899g / mL, the concentration of HMPP is 3.84% of the monomeric HEMA mass, and the concentration of EGDMA is 14.6% of the monomeric HEMA monomer.

[0048] (2) Coat the pre-polymerization liquid on the surface of the substrate, in a vertical uniform magnetic field of 300 Gs (the direction of the magnetic field is perpendicular to the surface of the substrate), and cure it with a UV lamp for 60 seconds. 90µm, 100µm, 110µm, 120µm, 130µm bottom film, in which the bottom film is embedded with a vertically arranged 1D photonic crystal structure.

[0049] figure 2 It is the spectrog...

Embodiment 3

[0051] (1) The method in Example 2 was used to prepare a bottom film with a thickness of 100 μm.

[0052] (2) The surface of the bottom layer film obtained in (1) is coated with pre-polymerization solution, and cured by a UV lamp for 60 seconds in a uniform magnetic field of the same strength inclined at 30° to the surface of the substrate to obtain thicknesses of 30µm, 40µm, and 50µm respectively. , 60µm, and 70µm top film, the bottom film is embedded with a vertically arranged 1D photonic crystal structure, and the top film is embedded with photonic crystal films of different thicknesses arranged at an angle of 30°. The thickness of the photonic crystal film The order is 130µm, 140µm, 150µm, 160µm, 170µm.

[0053] image 3 It is an actual picture of the bottom layer film with a thickness of 100 μm obtained in Example 3 during the deflection of the observation angle from -60° to 60°, taking pictures at intervals of 15° deflection.

[0054] Figure 4 It is the reflectance s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com