Web guiding device and device for handling material webs

A technology of guiding device and material width, which is applied in the direction of thin material handling, coiling strip, transportation and packaging, etc. It can solve the problems of inapplicable stress regulator, etc., and achieve the effect of improving service life and avoiding vibration or swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

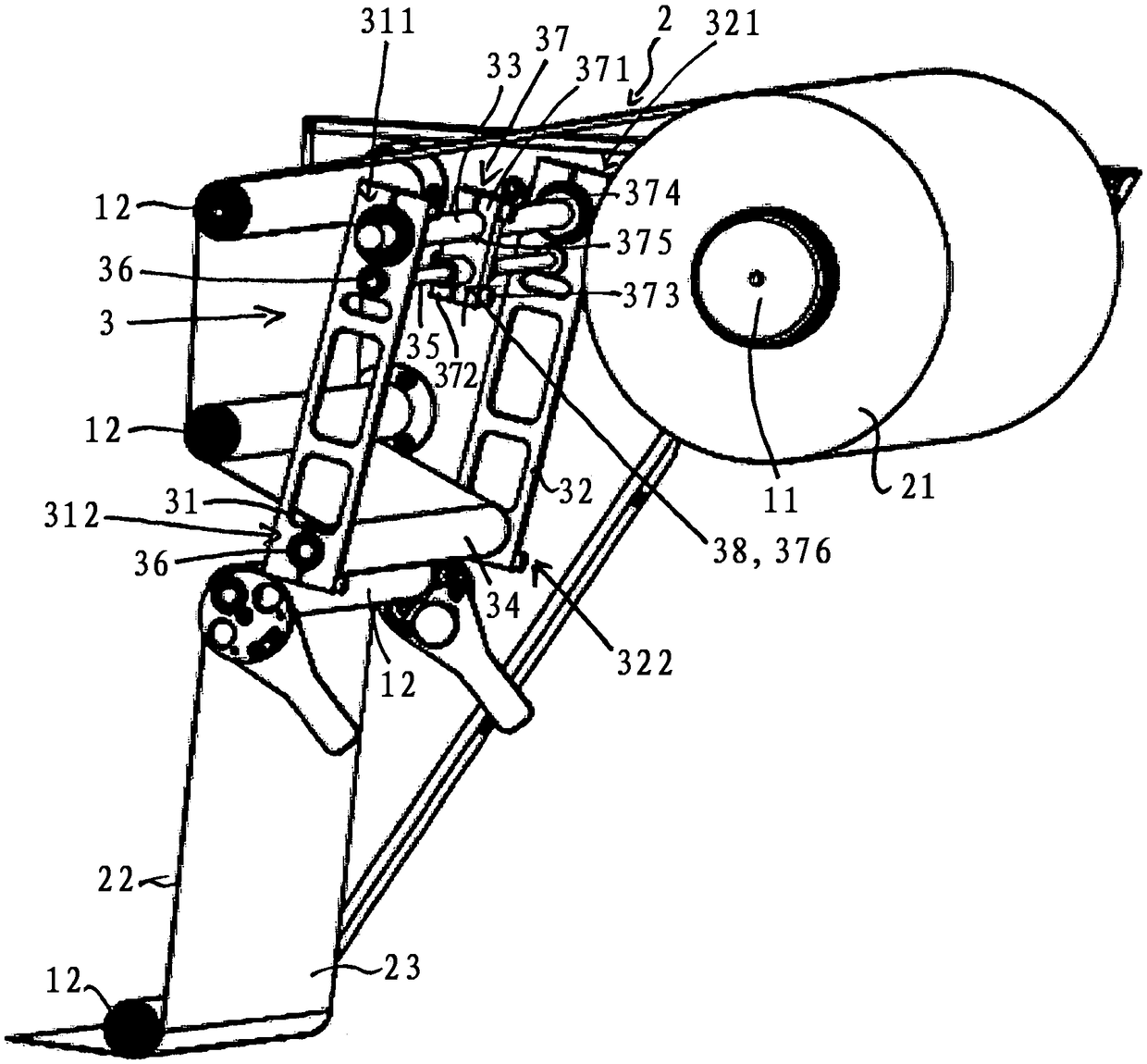

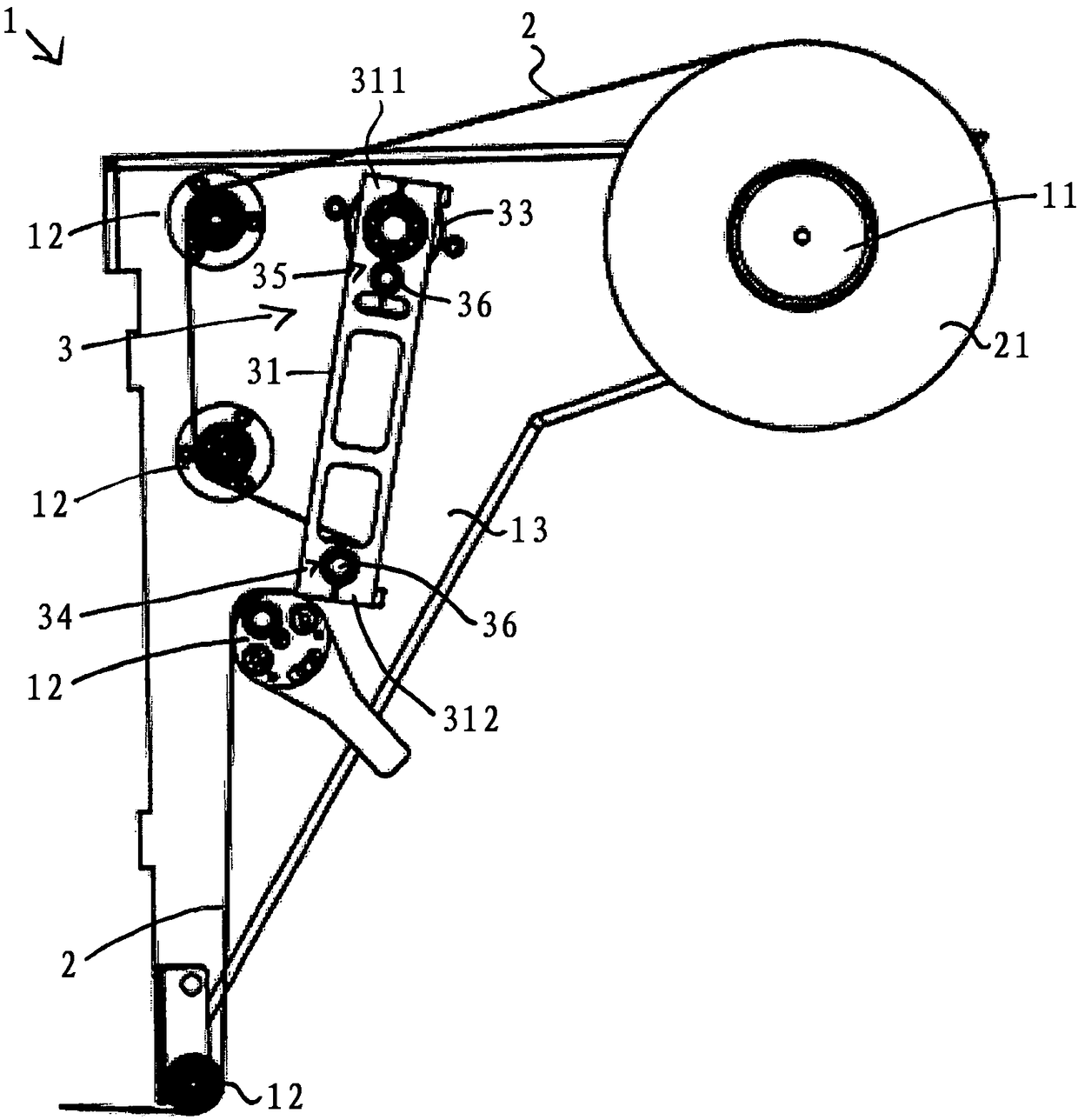

[0042] figure 1 and figure 2The part of the plant 1 for processing a material web 2 which is responsible for supplying the web is shown. The material web 2 is provided on a reel 21 , which is supported on the roller 11 of the device 1 . The uncoiled material web 2 is fed to the processing device by means of a plurality of deflection rollers 12 which are fixedly and rotatably arranged on a frame 13 of the device 1 . Actual processing devices, such as printing stations or embossing stations, are not shown in the figures.

[0043] If the material web is introduced obliquely when loading the new reel 21 , different tensile forces on the opposite sides 22 , 23 of the material web result when the material web 2 is drawn in. This can lead to web breaks, which require the device 1 to be taken out of operation.

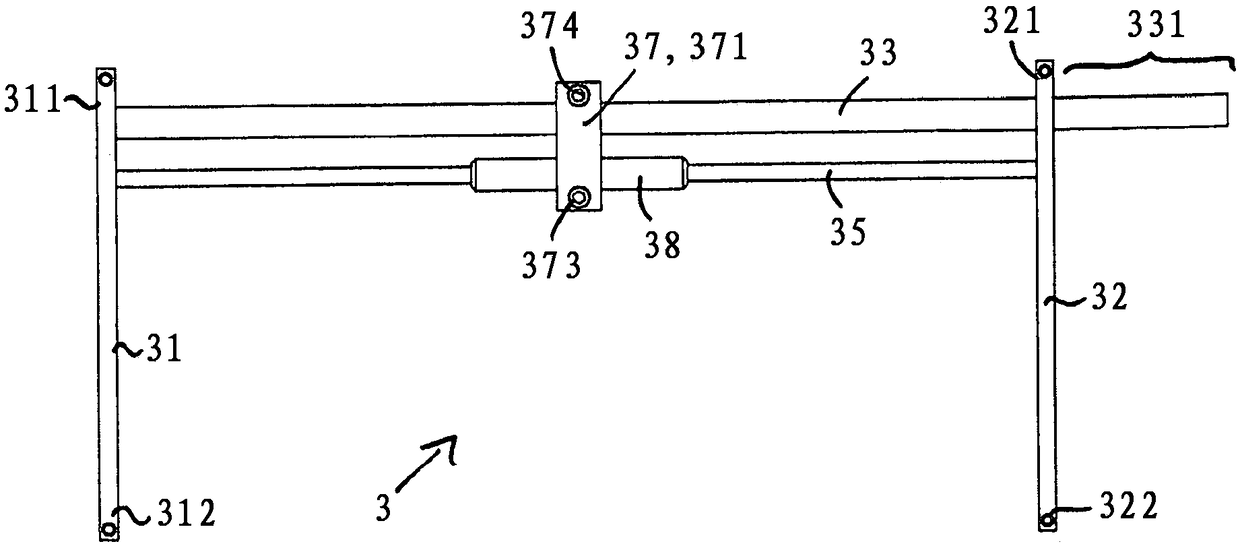

[0044] To prevent this, the device 1 includes a web guide 3 . The web guiding device comprises two frame elements 31 , 32 which are pivotably mounted with their respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com