Brewing water injection device

A brewing and water injection ring technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of high equipment cost, high failure rate in use, failure to meet standardization and large cup output, etc., to reduce the failure rate and The effect of equipment cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

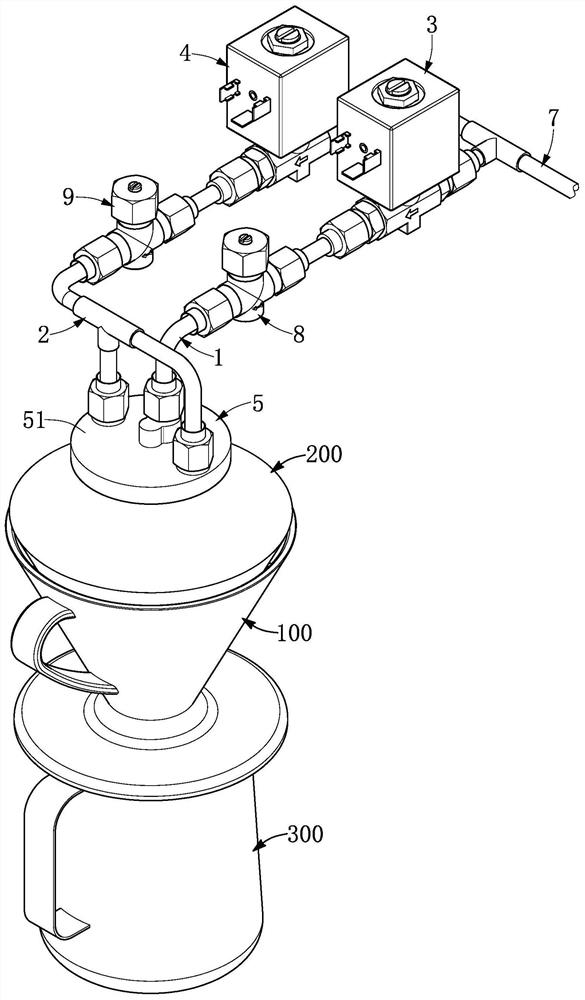

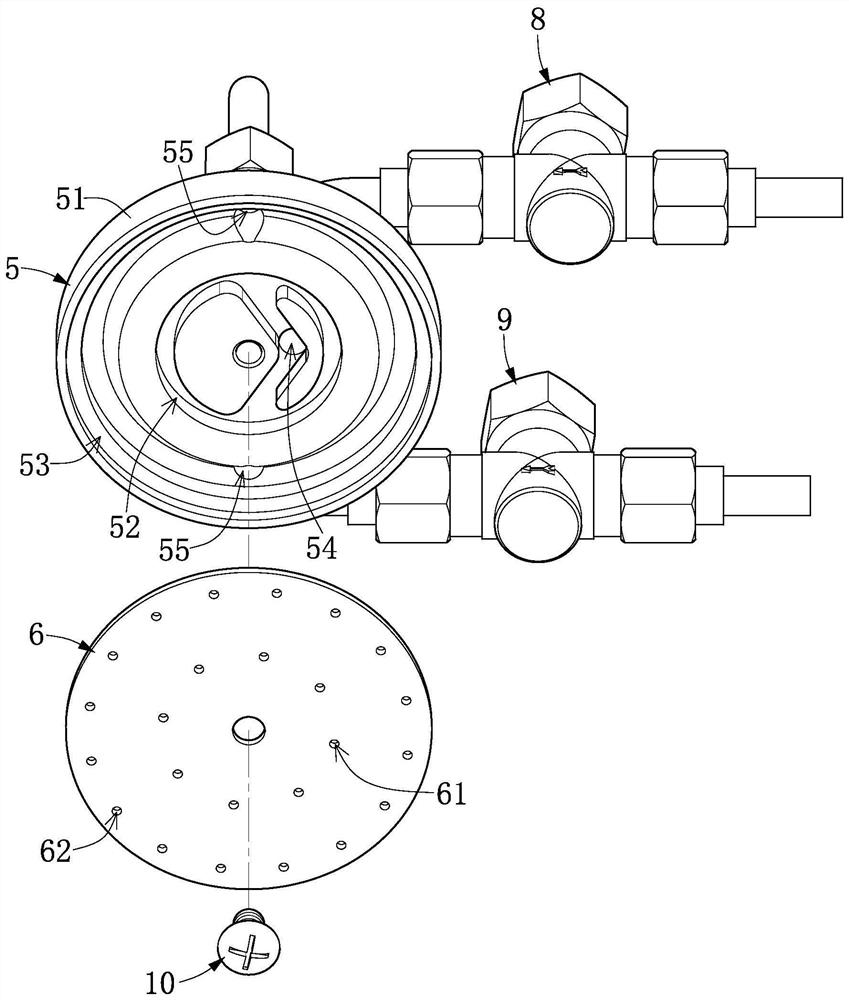

[0028] see figure 1 and figure 2 , the present invention provides a brewing water injection device, comprising an inner water injection ring hot water pipe 1, an outer water injection ring hot water pipe 2, a first solenoid valve 3, a second solenoid valve 4, a water injection head 5 and a Water injection sheet6.

[0029] One end of the inner water injection ring hot water pipe 1 and one end of the outer water injection ring hot water pipe 2 are connected to a hot water input port 7, and the hot water input port 7 can be connected to a hot water supply device (not shown) for Convey hot water to inner water injection ring hot water pipe 1 and outer water injection ring hot water pipe 2. The inner water injection ring hot water pipe 1 can be regarded as the first ring hot water pipe, and the outer water injection ring hot water pipe 2 can be regarded as the second ring hot water pipe. The hot water supply device may include a hot water boiler, a flow meter, a pump, etc., whi...

no. 2 example

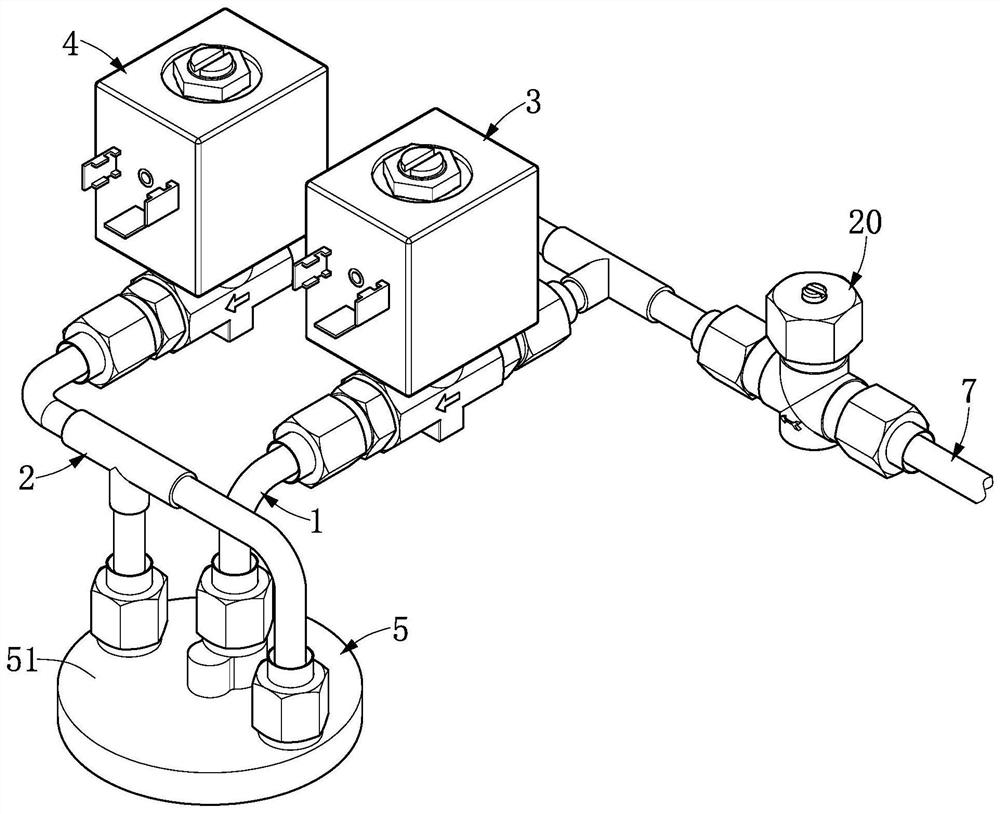

[0040] see image 3 , in this embodiment, the inner water injection ring hot water pipe 1 and the outer water injection ring hot water pipe 2 can also be provided with a throttle valve 20 at the upstream position (front end), and the first electromagnetic valve 3 and the second electromagnetic valve 4 are simultaneously Open, can spray a larger area, only open one of the solenoid valves (the first solenoid valve 3 or the second solenoid valve 4), because of the same water flow, the water injection holes (the inner ring water injection hole 61, the outer ring water injection hole 62 ) is less, the water flow speed is faster, which can stir the ingredients and improve the brewing effect.

no. 3 example

[0042] see Figure 4 and Figure 5 , in this embodiment, if a larger-capacity filter cup needs to be brewed, the water injection sheet 6 can be provided with a third ring water injection hole 63 with a larger spraying range, and the water injection head 5 is correspondingly provided with a third ring hot water channel 57, add a third ring hot water pipe 30, so that hot water can be transported through the third ring hot water pipe 30 to the third ring hot water channel 57 of the water injection head 5 and the third ring water injection hole 63 of the water injection sheet 6 downward Water injection, the third ring water injection can also be used to moisten the upper end of the cone filter paper, so that the cone filter paper can be attached to the filter cup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com