Wall grinding system and mounting method thereof

A technology for grinding walls and mounting boards. It is used in grinding machines, portable grinding machines, grinding/polishing equipment, etc. It can solve the problems of wall collision, secondary damage, and hand-held operation fatigue, so as to improve accuracy, easily and stably lift. , Improve the quality and efficiency of the grinding wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

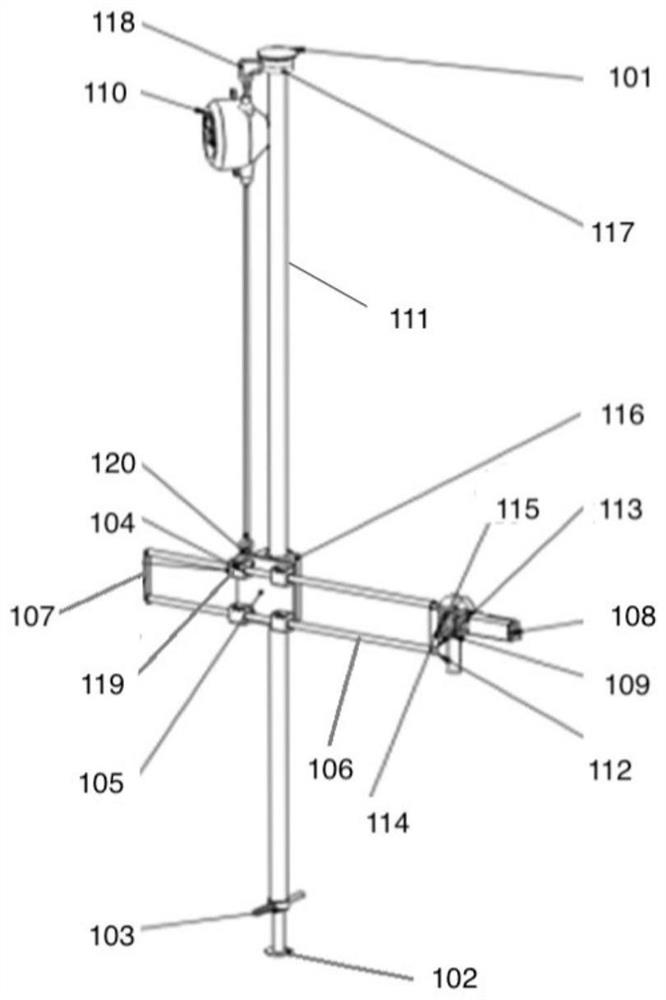

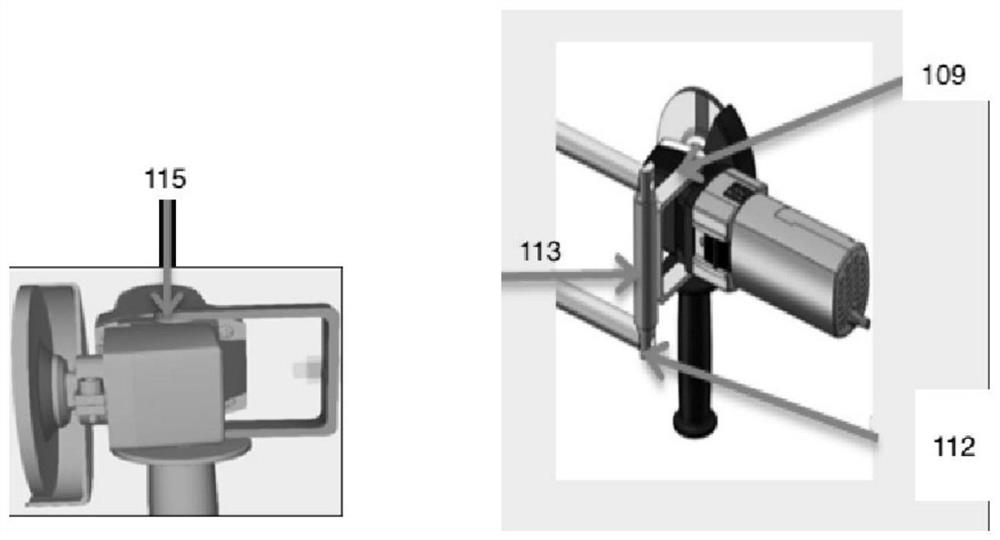

[0042] figure 1 It is a schematic diagram of the main components of the wall grinding system according to the first embodiment of the present invention. figure 2 is a schematic diagram of the main components of the connecting device of the wall grinding system according to the first embodiment of the present invention.

[0043] Such as figure 1 and figure 2 As shown, the wall grinding system of the first embodiment of the present invention includes a wall grinding device 108, a labor-saving mechanism and a connecting device, and the wall grinding device 108 is connected with the labor-saving mechanism by the connecting device. Wherein, the labor-saving mechanism includes: a support device, a movable device and a spring balance device; wherein, the movable device is connected with the supporting device through a connecting part; wherein, the wall grinding device is fixed at one end of the movable device; and wherein , the spring balancing device is respectively connected t...

Embodiment 2

[0062]The labor-saving mechanism of the present invention can adopt different connection modes according to carrying different wall grinding devices. The connection device can be selected according to the weight and power of the wall milling device. For the connection device of the U-shaped pull ring of the first embodiment, the load-bearing force is limited, which corresponds to the light weight and general power wall grinding device such as the angle grinder itself, but for the high power and heavy weight wall grinding device, its own weight The operating load is very large, and the first U-shaped ring connection method cannot be used. Thereby, the present invention researches another kind of connection device, carries out the connection of the second mode. It will be explained in detail below.

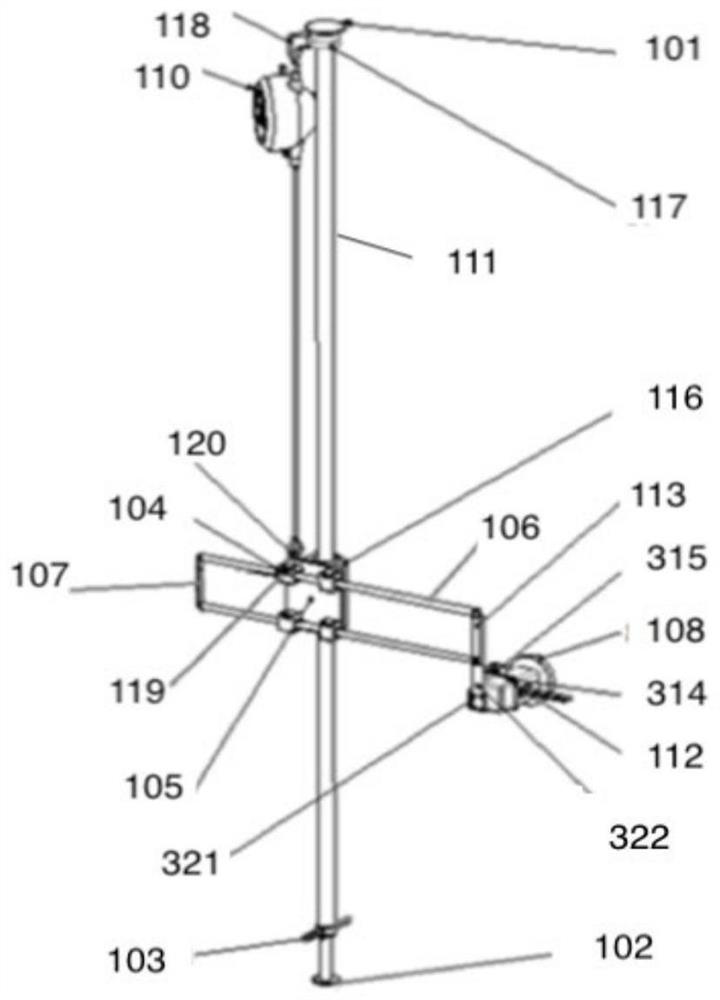

[0063] Next, image 3 It is a schematic diagram of the main components of the wall grinding system according to the second embodiment of the present invention. Figure 4 is a sc...

Embodiment 3

[0070] As mentioned above, the labor-saving mechanism of the present invention can adopt different connection methods according to carrying different wall grinding devices. The connection device can be selected according to the weight and power of the wall milling device. For light weight wall grinding devices such as the angle grinder itself, the connection device of the U-shaped pull ring of the first embodiment is used for connection, but for high power, heavy weight wall grinding devices, the connection device of the second embodiment is used to connect. Further, under the complex construction site environmental conditions, the wall grinding device needs to be rotated universally to realize 360-degree rotation and operation, and it is necessary to operate in narrow spaces such as corners and edges without dead angles.

[0071] For this reason, the wall grinding system of the third embodiment just arises at the historic moment.

[0072] Next, Figure 5 It is a schematic ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap