Return air purification system of ship air conditioner

A technology of purification system and air purification device, applied in the direction of hull ventilation/heating/cooling, ship components, ship construction, etc., can solve the problem that fresh air cannot be fully exchanged, increase air conditioning load and power load, threaten the health of crew, etc. The problem is to ensure the return air volume and return air uniformity, reduce the construction amount, and improve the return air purification and treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

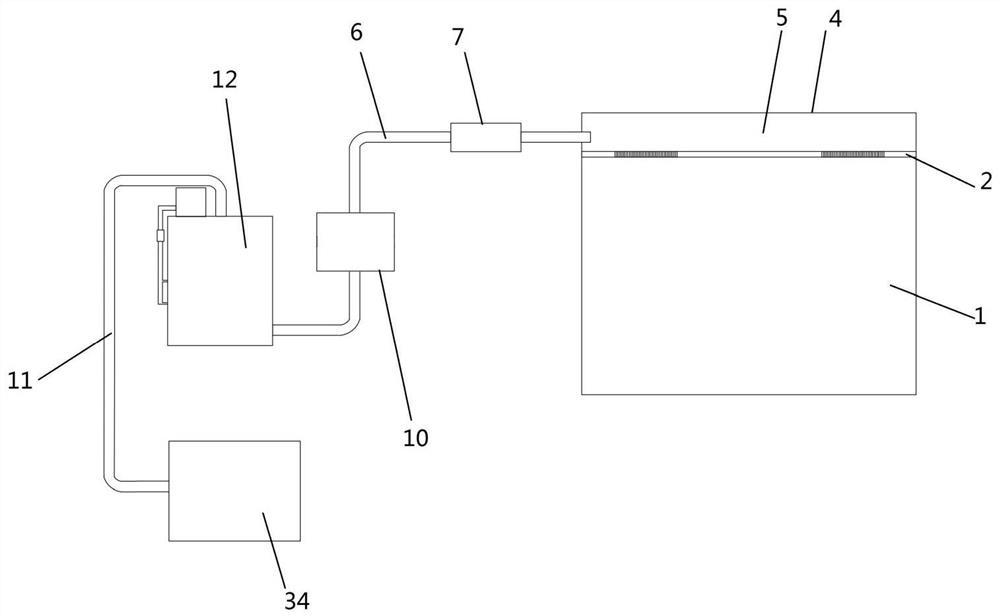

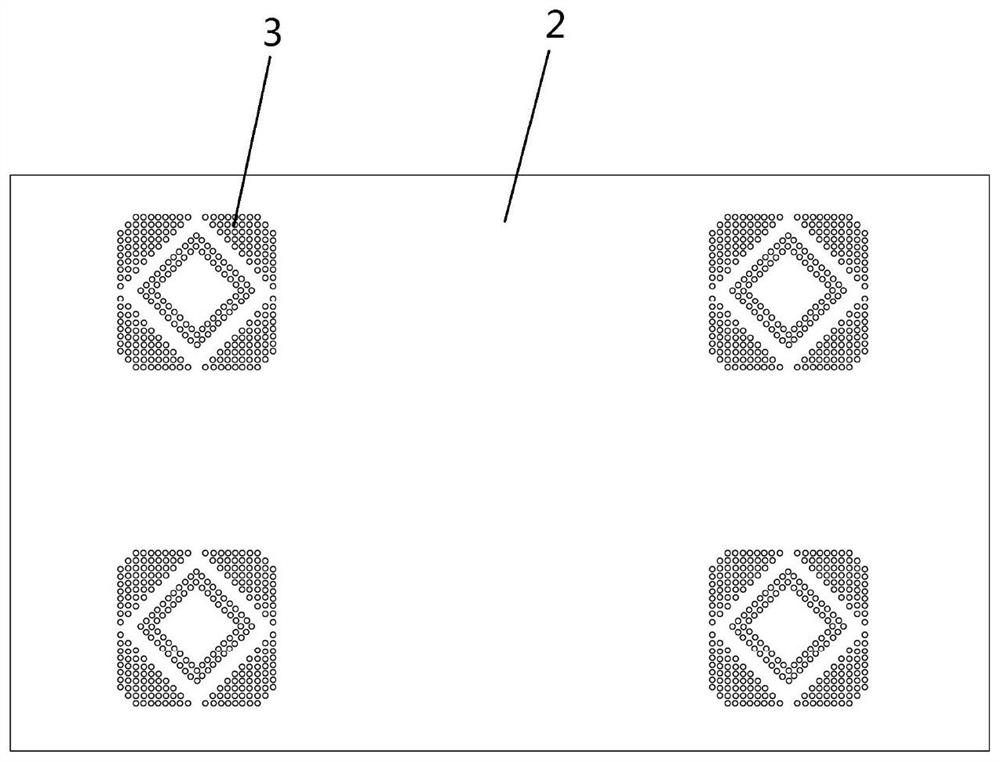

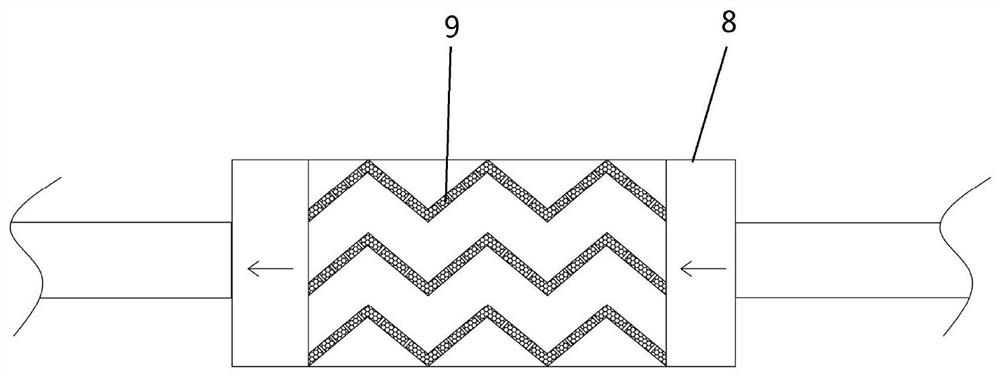

[0026] The embodiment of the present invention discloses a ship air conditioning return air purification system, such as figure 1 with figure 2 As shown, it includes a central air conditioner 34, an air cleaning device 12, a return fan 10, a return air chamber 5 and a return air outlet 3, and the return air chamber 5 is a sealed cavity formed between the ceiling 2 in the ship cabin 1 and the ship deck 4 Room, the ceiling 2 in the ship cabin 1 is provided with a return air outlet 3 connected with the space in the ship cabin 1, the number of the return air outlet 3 can be set according to the return air volume of the air conditioning system, and the return air outlet 3 is composed of multiple The shape of the return air port 3 can be round or square. The return air chamber 5 communicates with the air inlet of the return fan 10 through the first return air pipe 6. The air outlet of the return fan 10 passes through the second return air The pipe 11 communicates with the air retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com