A fan silencer for a dust collector

A technology of muffler and dust collector, which is applied to the components of pumping device for elastic fluid, machine/engine, mechanical equipment, etc. The effect of weight, improving service life and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

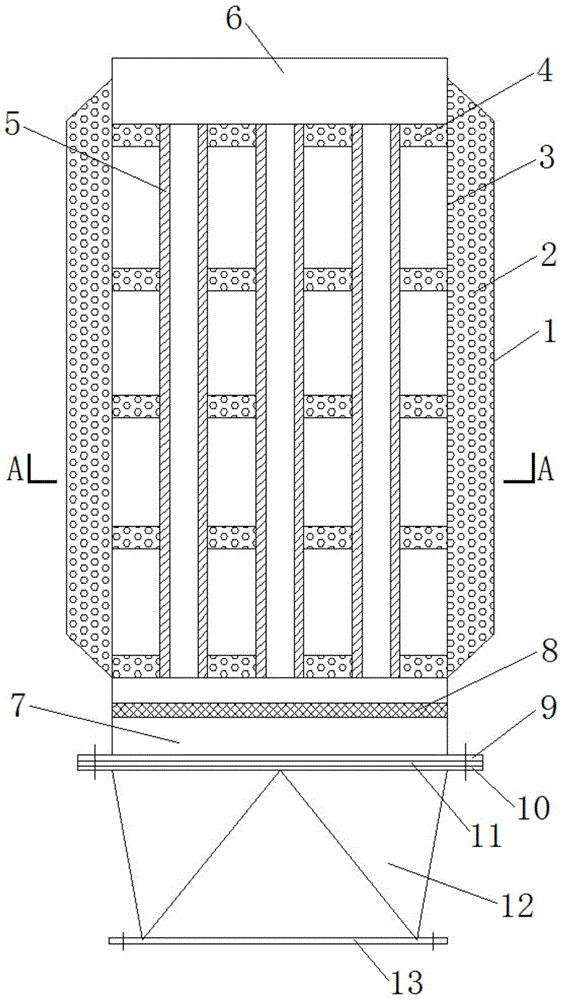

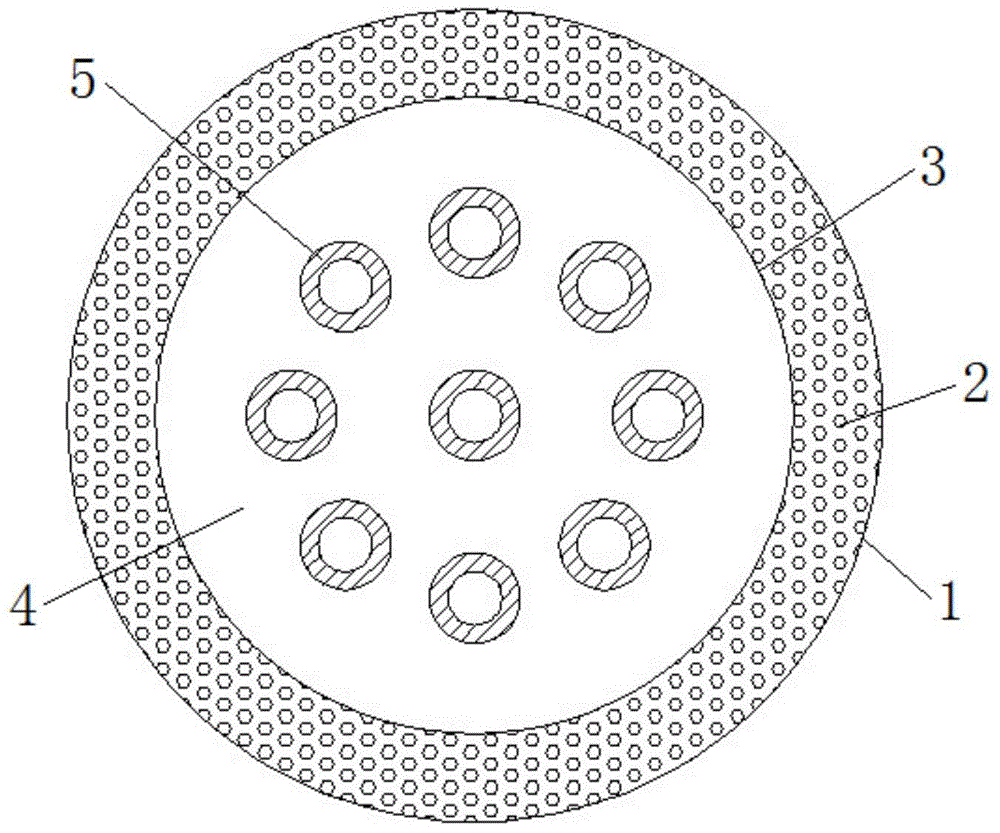

[0023] combine figure 1 and figure 2 , a fan muffler for a dust collector in this embodiment includes an outer shell 1, an inner shell 3, a sound-absorbing cotton 2 arranged between the outer shell 1 and the inner shell 3, a sound-absorbing plate 4, a porous sound-absorbing pipe 5, and a filter screen 8 and the fan connecting pipe 12, the outer shell 1 and the inner shell 3 form a cavity, and the cavity is filled with sound-absorbing cotton 2, and the side wall of the inner shell 3 that is in contact with the sound-absorbing cotton 2 is provided with sound-absorbing holes, and the two ends of the inner shell 3 are respectively The air outlet 6 and the air inlet 7, two or more sound-absorbing plates 4 are arranged in sequence in the inner shell 3, and the sound-absorbing plates 4 are perpendicular to the air inlet direction, specifically in this embodiment, according to the fan power and the environmental noise level size, the sound-absorbing board 4 is provided with 5 pieces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com