Protective device for three-dimensional warehouse

A protective device and three-dimensional warehouse technology, applied in storage devices, transportation and packaging, etc., can solve the problems of unfavorable protection of personnel safety equipment, etc., and achieve the effect of good protection, good protection and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

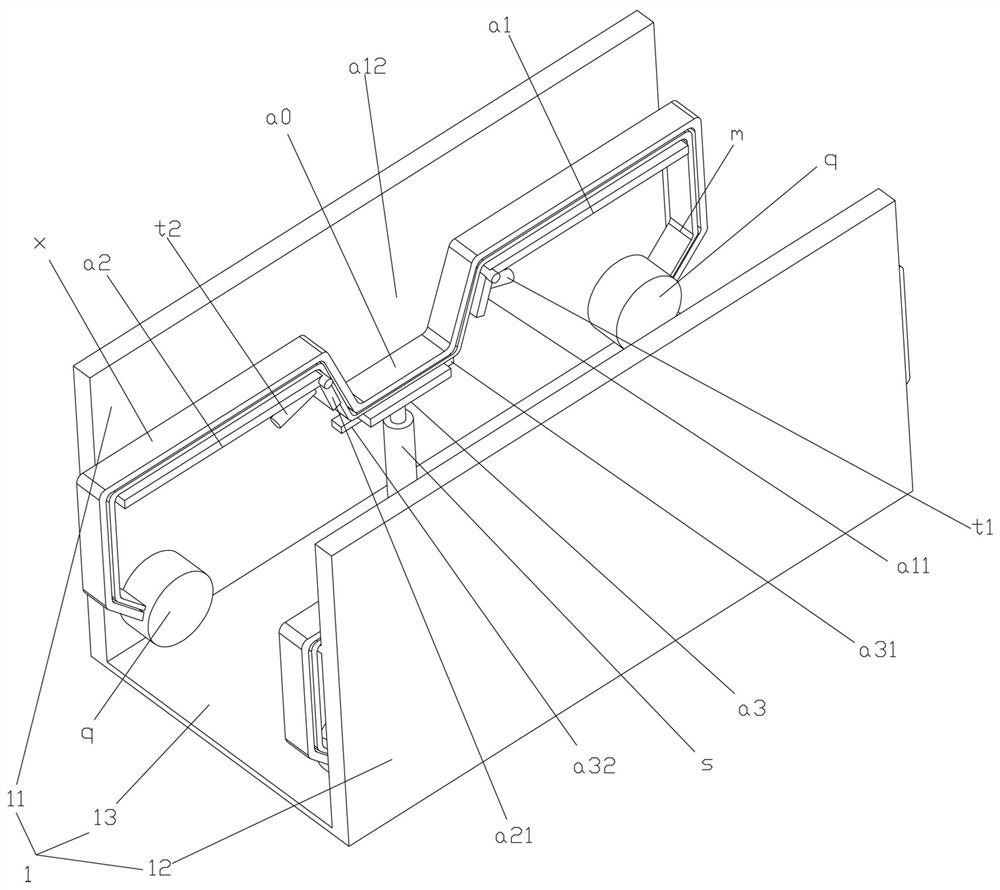

[0032] Example 1, such as Figure 1-8 As shown, this embodiment is essentially formed by the further transformation of the stacker, and this structure is specially designed for the handling robot with wheels on the left and right sides, specifically:

[0033] A safety protection mechanism for a three-dimensional warehouse handling robot, comprising a stacker platform 1, the stacker platform 1 includes a left side plate 11, a right side plate 12, and the bottom of the left side plate 11 and the right side plate 12 The bottom and side plates 13 connected between them are also the U-shaped structure of the conventional stacker loading platform. The area surrounded by this U-shaped structure is to park the handling robot. On the one hand, the existing stacker does not have The robot is well limited. On the other hand, the robot is not effectively protected during the operation of the stacker, which may cause safety accidents such as falling goods and hitting people or equipment. E...

Embodiment 2

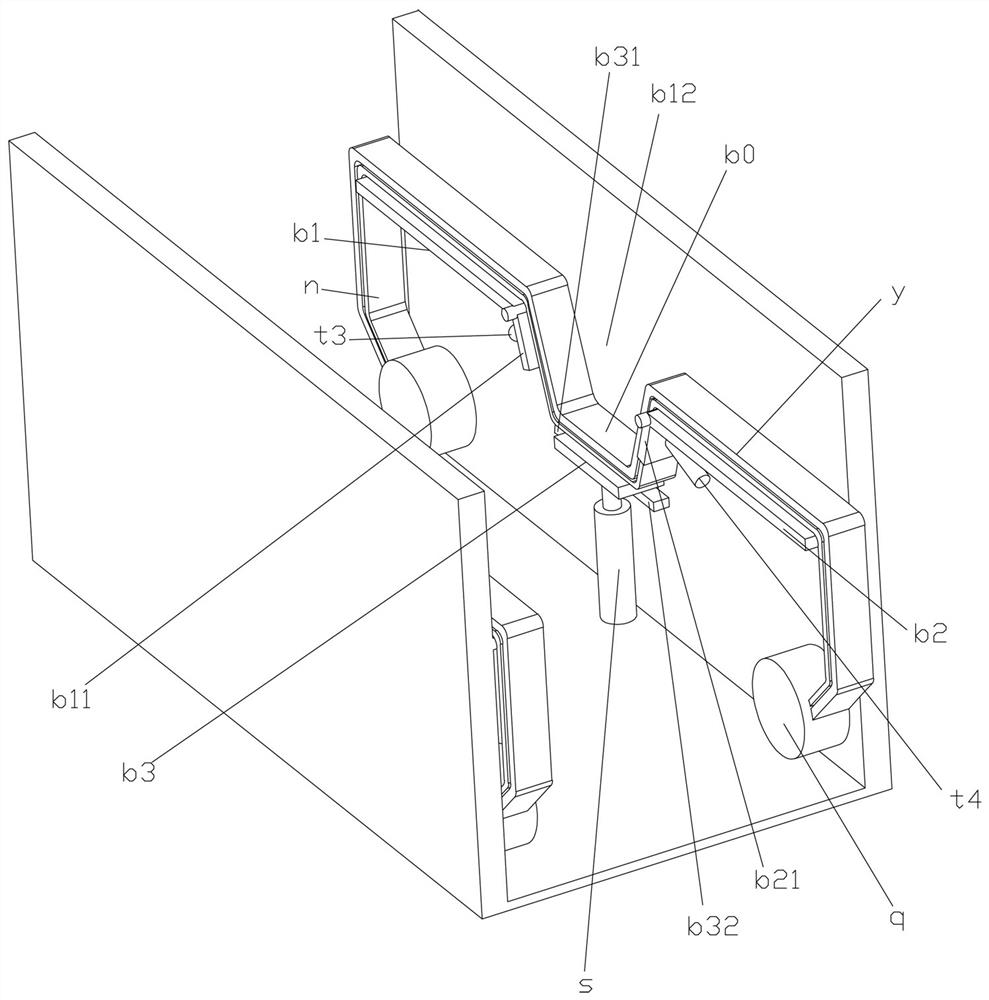

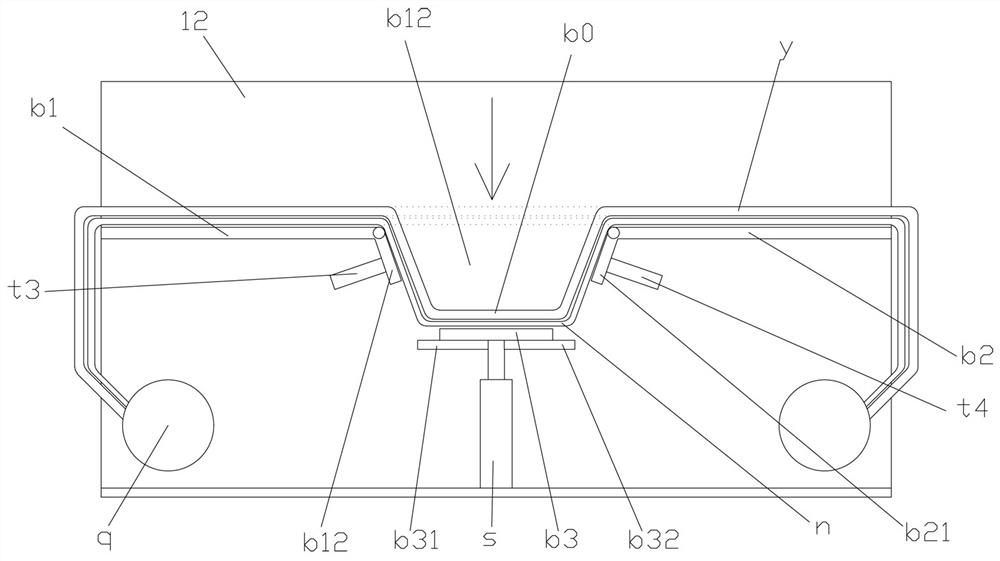

[0044] Example 2, such as Figure 9-12 As shown, a protective device for a three-dimensional warehouse, this embodiment is essentially an improvement on the exit positions on the front and rear sides of the stacker, mainly to effectively improve the gap between the stacker and the shelf. impact, and the structure inside the stacker can adopt the structural design of Embodiment 1.

[0045] The protective device of this embodiment includes a stacker platform 1, and the stacker platform 1 includes a left side plate 11, a right side plate 12, and a bottom plate connected between the left side plate 11 and the right side plate 12. Bottom side plate 13, on the right side part of described left side plate 11, the left guide rail assembly for the left side wheel part of three-dimensional storehouse handling robot j to walk back and forth is installed, on the left side part of described right side plate 12, is installed The right guide rail assembly for the right side wheel part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com